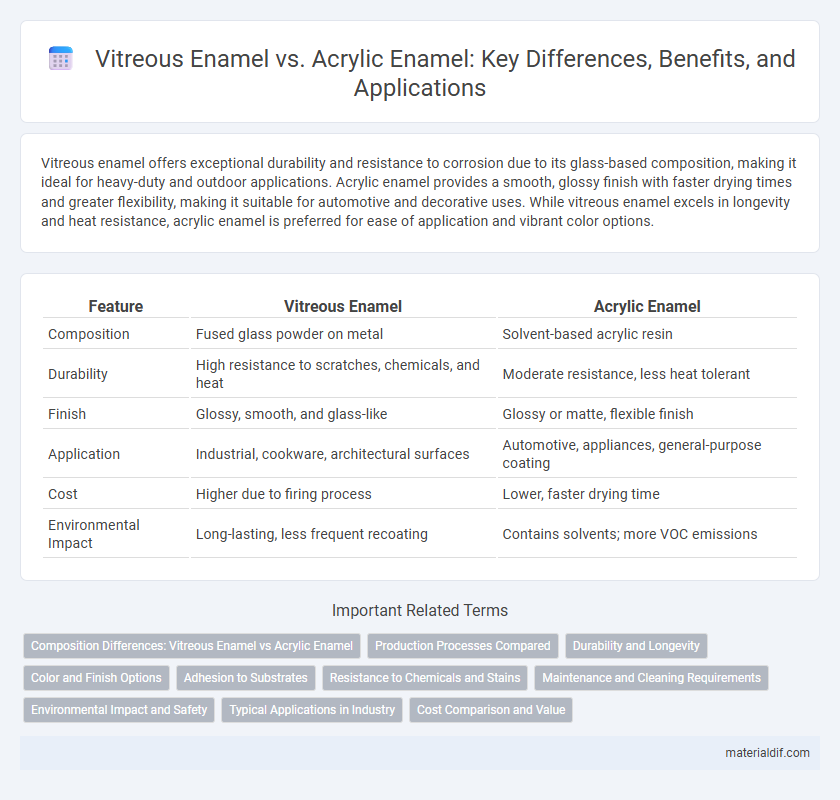

Vitreous enamel offers exceptional durability and resistance to corrosion due to its glass-based composition, making it ideal for heavy-duty and outdoor applications. Acrylic enamel provides a smooth, glossy finish with faster drying times and greater flexibility, making it suitable for automotive and decorative uses. While vitreous enamel excels in longevity and heat resistance, acrylic enamel is preferred for ease of application and vibrant color options.

Table of Comparison

| Feature | Vitreous Enamel | Acrylic Enamel |

|---|---|---|

| Composition | Fused glass powder on metal | Solvent-based acrylic resin |

| Durability | High resistance to scratches, chemicals, and heat | Moderate resistance, less heat tolerant |

| Finish | Glossy, smooth, and glass-like | Glossy or matte, flexible finish |

| Application | Industrial, cookware, architectural surfaces | Automotive, appliances, general-purpose coating |

| Cost | Higher due to firing process | Lower, faster drying time |

| Environmental Impact | Long-lasting, less frequent recoating | Contains solvents; more VOC emissions |

Composition Differences: Vitreous Enamel vs Acrylic Enamel

Vitreous enamel is composed of powdered glass fused to a substrate through firing at high temperatures, resulting in a durable, glassy coating with excellent resistance to heat and corrosion. Acrylic enamel consists of synthetic resin polymers combined with pigments and solvents, offering flexible, fast-drying coatings suitable for various surfaces but with less heat resistance than vitreous enamel. The fundamental composition difference lies in vitreous enamel's inorganic glass base versus acrylic enamel's organic polymer base, impacting durability, heat resistance, and environmental stability.

Production Processes Compared

Vitreous enamel production involves fusing powdered glass onto metal at temperatures between 750-850degC, creating a durable, glossy coating through a high-temperature vitrification process. In contrast, acrylic enamel is produced by applying pigmented acrylic resin via spray or brush, cured at room temperature or low heat for rapid drying and flexibility. The vitreous enamel process offers superior hardness and chemical resistance, while acrylic enamel allows for easier application and faster turnaround in manufacturing.

Durability and Longevity

Vitreous enamel offers superior durability and longevity due to its glass-based coating fused to metal at high temperatures, providing exceptional resistance to corrosion, scratching, and fading. Acrylic enamel, while easier to apply and faster to dry, usually lacks the same hard-wearing properties and tends to degrade faster under environmental stress. For applications demanding long-term protection and wear resistance, vitreous enamel remains the preferred choice.

Color and Finish Options

Vitreous enamel offers a rich, glossy finish with vibrant, long-lasting colors that resist fading and wear, ideal for durable applications. Acrylic enamel provides a wide range of colors with a smooth, semi-gloss to matte finish, allowing greater flexibility in design aesthetics. Both enamels ensure excellent coverage, but vitreous enamel excels in hardness and gloss retention, while acrylic enamel is prized for quick drying times and ease of application.

Adhesion to Substrates

Vitreous enamel offers exceptional adhesion to metal substrates due to its fusion of powdered glass onto the surface at high temperatures, creating a durable, glassy coating that resists chipping and peeling. Acrylic enamel, a polymer-based coating, relies on chemical adhesion and often requires primers for effective bonding, making it less robust on bare metals compared to vitreous enamel. The thermal bonding process of vitreous enamel results in superior long-term durability and resistance to environmental factors, whereas acrylic enamel provides easier application but with comparatively lower adhesion strength.

Resistance to Chemicals and Stains

Vitreous enamel exhibits superior resistance to chemicals and stains due to its glassy, non-porous surface formed by fusing powdered glass to metal at high temperatures, making it highly durable against acids, alkalis, and various solvents. Acrylic enamel, being a synthetic polymer-based coating, offers moderate chemical resistance but is more prone to staining and degradation when exposed to harsh chemicals or prolonged exposure to UV light. The highly inert nature of vitreous enamel ensures long-term preservation of appearance and structural integrity in chemically aggressive environments compared to the relatively softer and more permeable acrylic enamel.

Maintenance and Cleaning Requirements

Vitreous enamel requires minimal maintenance due to its glass-like surface that resists stains, corrosion, and scratching, making cleaning simple with mild detergents and water. Acrylic enamel, while easier to repair, demands more frequent cleaning and careful handling to avoid surface damage, often needing specialized cleaners to maintain its gloss and prevent fading. Regular upkeep of vitreous enamel ensures longevity and preserves its smooth, non-porous finish compared to the more vulnerable acrylic enamel coating.

Environmental Impact and Safety

Vitreous enamel, composed of powdered glass fused to metal at high temperatures, is highly durable and non-toxic, making it environmentally friendly due to its recyclability and long lifespan. Acrylic enamel, a synthetic resin-based coating, offers lower durability and contains volatile organic compounds (VOCs) that contribute to air pollution and pose health risks during application. The environmental impact of vitreous enamel is significantly lower compared to acrylic enamel, which requires careful handling and produces more hazardous waste.

Typical Applications in Industry

Vitreous enamel is commonly used in industrial applications requiring high durability and resistance to corrosion, such as cookware, architectural panels, and chemical processing equipment. Acrylic enamel is preferred for automotive coatings and household appliances due to its faster drying time and flexibility. Both coatings serve distinct purposes based on their composition, with vitreous enamel excelling in heavy-duty environments and acrylic enamel favored for aesthetic finishes and ease of application.

Cost Comparison and Value

Vitreous enamel typically incurs higher upfront costs due to its durable glass-like coating created by fusing powdered glass onto metal at high temperatures. Acrylic enamel offers a more budget-friendly option with faster application and lower material costs but may lack the long-term resistance and gloss retention of vitreous enamel. When considering value, vitreous enamel provides superior durability and longevity, making it cost-effective over time despite its initial expense.

Vitreous enamel vs acrylic enamel Infographic

materialdif.com

materialdif.com