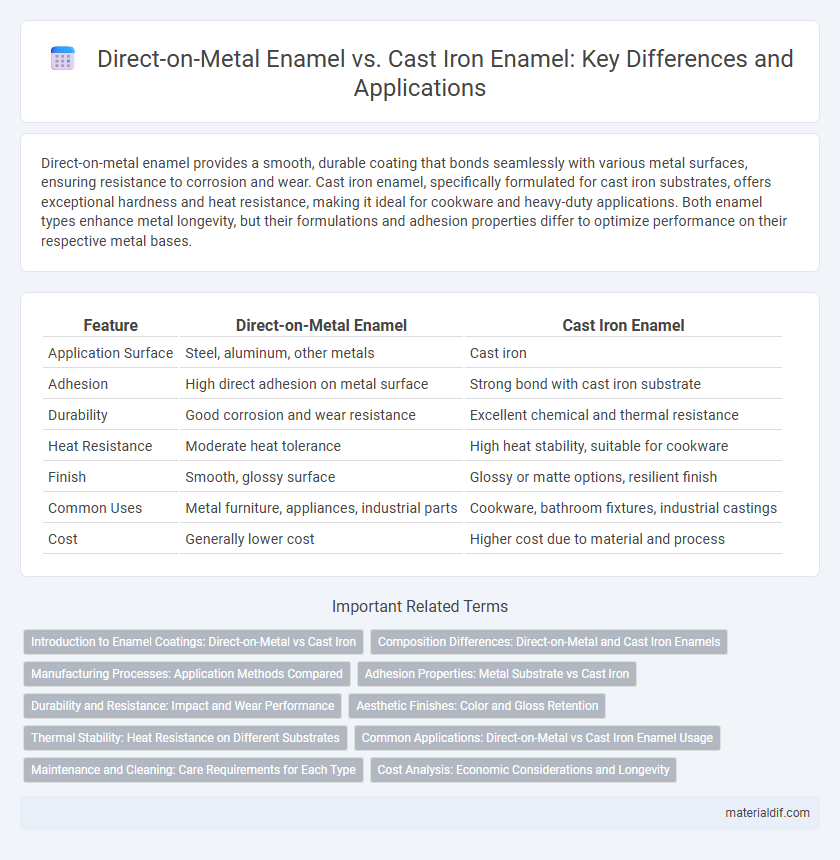

Direct-on-metal enamel provides a smooth, durable coating that bonds seamlessly with various metal surfaces, ensuring resistance to corrosion and wear. Cast iron enamel, specifically formulated for cast iron substrates, offers exceptional hardness and heat resistance, making it ideal for cookware and heavy-duty applications. Both enamel types enhance metal longevity, but their formulations and adhesion properties differ to optimize performance on their respective metal bases.

Table of Comparison

| Feature | Direct-on-Metal Enamel | Cast Iron Enamel |

|---|---|---|

| Application Surface | Steel, aluminum, other metals | Cast iron |

| Adhesion | High direct adhesion on metal surface | Strong bond with cast iron substrate |

| Durability | Good corrosion and wear resistance | Excellent chemical and thermal resistance |

| Heat Resistance | Moderate heat tolerance | High heat stability, suitable for cookware |

| Finish | Smooth, glossy surface | Glossy or matte options, resilient finish |

| Common Uses | Metal furniture, appliances, industrial parts | Cookware, bathroom fixtures, industrial castings |

| Cost | Generally lower cost | Higher cost due to material and process |

Introduction to Enamel Coatings: Direct-on-Metal vs Cast Iron

Direct-on-metal enamel coatings bond directly to metal surfaces, offering superior corrosion resistance and enhanced durability for steel and aluminum substrates. Cast iron enamel involves applying vitreous enamel to pre-cast iron, providing excellent heat resistance and a smooth, glass-like finish ideal for cookware and architectural elements. Understanding the differences in adhesion, thermal properties, and substrate compatibility is essential for selecting the appropriate enamel coating in industrial and decorative applications.

Composition Differences: Direct-on-Metal and Cast Iron Enamels

Direct-on-metal enamel typically contains a higher concentration of silica and alkali oxides, promoting better adhesion and flexibility on steel and other ferrous metals. Cast iron enamel formulations incorporate greater amounts of fluxes like borax and lead oxides, optimizing durability and resistance to thermal shock specifically for cast iron substrates. These compositional differences directly influence the enamel's bonding strength, wear resistance, and suitability for specific metal types in industrial applications.

Manufacturing Processes: Application Methods Compared

Direct-on-metal enamel involves applying enamel directly to a clean, treated metal surface through spray or dip coating, ensuring strong adhesion and a smoother finish ideal for steel substrates. Cast iron enamel requires a more controlled application, often using wet-on-wet techniques or ground coat layers to accommodate the rougher texture and variable porosity of cast iron, preventing defects like cracking or peeling. Differences in temperature profiles during firing are critical; direct-on-metal enamel benefits from rapid firing cycles, while cast iron enamel demands slower, more gradual heating and cooling to maintain coating integrity.

Adhesion Properties: Metal Substrate vs Cast Iron

Direct-on-metal enamel exhibits superior adhesion properties due to its compatibility with a smooth, homogeneous metal substrate, enabling a strong chemical bond and reducing the risk of exfoliation. Cast iron enamel systems face adhesion challenges because the porous and uneven surface of cast iron hinders enamel bonding, often necessitating primer layers to improve surface receptivity. The distinct microstructural differences between metal substrates and cast iron significantly influence enamel durability and resistance to mechanical stress.

Durability and Resistance: Impact and Wear Performance

Direct-on-metal enamel offers superior adhesion and resistance to chipping due to its strong chemical bonding with the metal substrate, making it highly durable under impact and wear conditions. Cast iron enamel typically exhibits exceptional hardness and wear resistance, benefiting from the robust composite structure formed during the casting process, which enhances its longevity in abrasive environments. Both types of enamel provide excellent protection, but direct-on-metal enamel excels in flexibility and impact resilience, whereas cast iron enamel is favored for heavy-duty durability in industrial applications.

Aesthetic Finishes: Color and Gloss Retention

Direct-on-metal enamel provides superior color vibrancy and gloss retention due to its strong adhesion and resistance to chipping. Cast iron enamel offers a durable finish with excellent gloss but may experience color fading over time under harsh conditions. Both types ensure aesthetic longevity, with direct-on-metal enamel excelling in maintaining vivid hues and consistent shine.

Thermal Stability: Heat Resistance on Different Substrates

Direct-on-metal enamel exhibits superior thermal stability due to its specialized formulation for bonding directly with metal substrates, allowing it to withstand high temperatures without cracking or discoloration. Cast iron enamel, while durable, may experience reduced heat resistance as the thicker substrate can expand and contract unevenly under thermal stress, potentially leading to enamel crazing. Heat resistance varies significantly between these enamels because the direct-on-metal type forms a stronger chemical bond, enhancing thermal shock resistance on metals like steel and aluminum.

Common Applications: Direct-on-Metal vs Cast Iron Enamel Usage

Direct-on-metal enamel is commonly applied in automotive parts, household appliances, and metal furniture due to its strong adhesion and corrosion resistance on steel substrates. Cast iron enamel is primarily used for cookware, bathtubs, and industrial equipment, offering excellent durability and heat resistance on cast iron surfaces. Both enameling types enhance protection and aesthetic appeal but are selected based on the underlying metal and intended application environment.

Maintenance and Cleaning: Care Requirements for Each Type

Direct-on-metal enamel requires regular cleaning with non-abrasive detergents to prevent surface degradation and maintain its glossy finish, as it is more prone to chipping due to its thinner application. Cast iron enamel, being thicker and more durable, tolerates harsher cleaning methods and is less susceptible to scratches, but still benefits from gentle cleaning to avoid wear over time. Both types demand avoidance of acidic or abrasive substances to preserve enamel integrity and ensure long-lasting performance.

Cost Analysis: Economic Considerations and Longevity

Direct-on-metal enamel generally offers a lower initial cost compared to cast iron enamel due to simpler application processes and reduced material expenses. Cast iron enamel, while more expensive upfront, provides superior durability and longer lifespan, potentially lowering lifetime maintenance and replacement costs. Economic considerations must balance immediate budget constraints with long-term investment benefits, emphasizing the trade-off between initial expenditure and extended performance.

Direct-on-metal enamel vs cast iron enamel Infographic

materialdif.com

materialdif.com