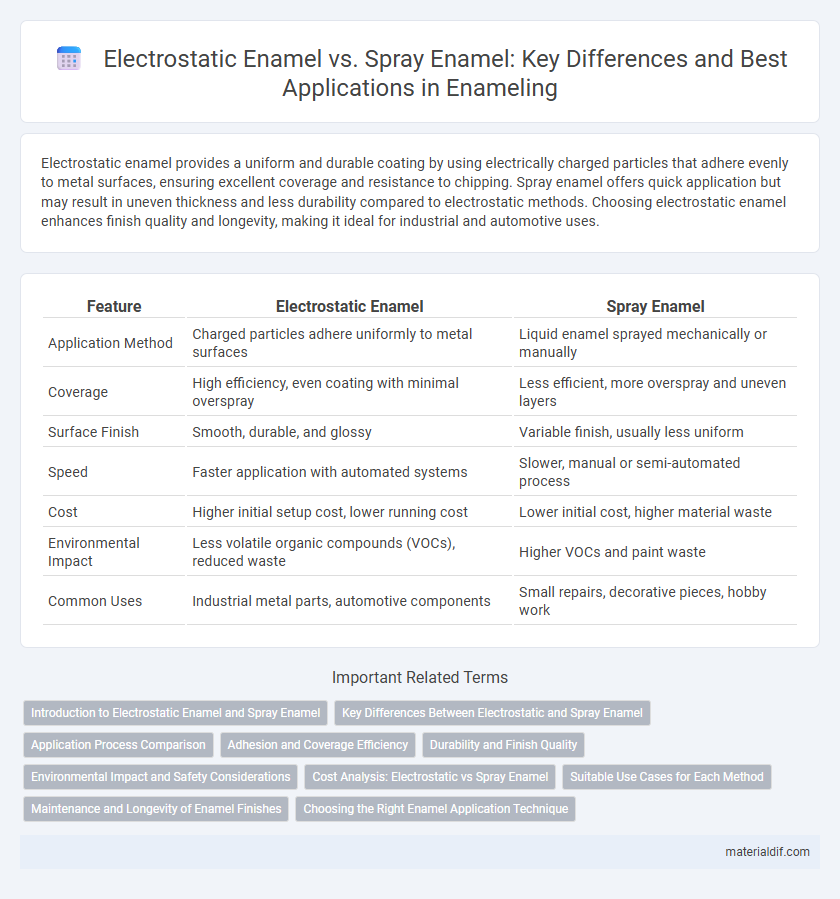

Electrostatic enamel provides a uniform and durable coating by using electrically charged particles that adhere evenly to metal surfaces, ensuring excellent coverage and resistance to chipping. Spray enamel offers quick application but may result in uneven thickness and less durability compared to electrostatic methods. Choosing electrostatic enamel enhances finish quality and longevity, making it ideal for industrial and automotive uses.

Table of Comparison

| Feature | Electrostatic Enamel | Spray Enamel |

|---|---|---|

| Application Method | Charged particles adhere uniformly to metal surfaces | Liquid enamel sprayed mechanically or manually |

| Coverage | High efficiency, even coating with minimal overspray | Less efficient, more overspray and uneven layers |

| Surface Finish | Smooth, durable, and glossy | Variable finish, usually less uniform |

| Speed | Faster application with automated systems | Slower, manual or semi-automated process |

| Cost | Higher initial setup cost, lower running cost | Lower initial cost, higher material waste |

| Environmental Impact | Less volatile organic compounds (VOCs), reduced waste | Higher VOCs and paint waste |

| Common Uses | Industrial metal parts, automotive components | Small repairs, decorative pieces, hobby work |

Introduction to Electrostatic Enamel and Spray Enamel

Electrostatic enamel applies a charged powder coating to metal surfaces, creating a durable, even finish through electrostatic attraction and heat curing, widely used in automotive and industrial applications. Spray enamel involves spraying liquid enamel paint onto surfaces, offering versatile color options and quick drying, ideal for smaller projects and touch-ups. Both methods enhance metal protection and aesthetics, with electrostatic enamel providing superior adhesion and uniformity compared to traditional spray enamel techniques.

Key Differences Between Electrostatic and Spray Enamel

Electrostatic enamel uses charged particles that adhere uniformly to surfaces through electrostatic attraction, resulting in a smooth, even coating with minimal overspray and better material efficiency. Spray enamel involves atomizing enamel into fine droplets sprayed onto a surface, allowing for quick application but often leading to higher material waste and less consistent coverage. Key differences include the precision and efficiency of electrostatic enamel compared to the faster but messier spray enamel method.

Application Process Comparison

Electrostatic enamel application utilizes charged particles that adhere uniformly to conductive surfaces, resulting in a smooth, even coating with minimal waste and faster curing times. Spray enamel, applied through pneumatic or airless spray guns, offers versatility for various surface types and shapes but often requires multiple passes and increased overspray management. The electrostatic method enhances precision and efficiency, making it ideal for industrial metal components, while spray enamel suits smaller projects and intricate details needing flexible coverage.

Adhesion and Coverage Efficiency

Electrostatic enamel provides superior adhesion due to the charged particles that uniformly attract to metal surfaces, ensuring a strong, durable bond. Spray enamel offers variable coverage efficiency depending on technique and environmental conditions, often resulting in uneven coating thickness. Electrostatic application maximizes material utilization and reduces overspray, enhancing overall coverage efficiency compared to traditional spray methods.

Durability and Finish Quality

Electrostatic enamel coating offers superior durability due to its strong adhesion and uniform coverage, resulting in a smooth, high-quality finish resistant to chipping and corrosion. Spray enamel provides more flexibility for complex shapes but often yields a less consistent finish with lower durability, prone to uneven thickness and faster wear. Choosing electrostatic enamel is ideal for applications requiring long-lasting protection and a flawless, professional appearance.

Environmental Impact and Safety Considerations

Electrostatic enamel application reduces overspray and minimizes volatile organic compound (VOC) emissions, making it more environmentally friendly than traditional spray enamel, which often releases higher levels of VOCs and hazardous particulates. The controlled deposition in electrostatic techniques enhances worker safety by limiting inhalation exposure and reducing flammability risks. Spray enamel requires extensive ventilation and personal protective equipment due to its airborne chemical particles and solvent content, increasing potential health hazards.

Cost Analysis: Electrostatic vs Spray Enamel

Electrostatic enamel application typically incurs higher upfront equipment costs but offers superior transfer efficiency, reducing paint waste and long-term material expenses compared to spray enamel. Spray enamel processes have lower initial investment but often lead to increased overspray and higher paint consumption, which elevates operational costs over time. Evaluating total cost of ownership reveals electrostatic systems are more cost-effective for large-scale or continuous production environments due to their precision and reduced material usage.

Suitable Use Cases for Each Method

Electrostatic enamel is ideal for coating metal surfaces with durability, commonly used in automotive parts and industrial equipment due to its uniform application and strong adhesion. Spray enamel excels in artistic projects and small-scale applications, offering versatility and ease of touch-up on household items and decorative surfaces. Choosing between these methods depends on the surface type, desired finish quality, and production scale.

Maintenance and Longevity of Enamel Finishes

Electrostatic enamel offers superior adhesion and uniform coating, significantly enhancing maintenance ease and extending the longevity of enamel finishes by resisting chipping and corrosion. Spray enamel provides quick application but often results in thinner, less durable layers that require more frequent touch-ups and maintenance. Choosing electrostatic enamel can reduce long-term upkeep costs and improve finish durability in harsh environments.

Choosing the Right Enamel Application Technique

Electrostatic enamel offers superior adhesion and uniform coating by using electrically charged particles that bond efficiently to metal surfaces, reducing overspray and material waste. Spray enamel provides versatility and ease of application, particularly suitable for irregular shapes or touch-up tasks, but often results in less consistent coverage compared to electrostatic methods. Selecting the right enamel application technique depends on project requirements, surface complexity, and desired finish quality.

Electrostatic enamel vs spray enamel Infographic

materialdif.com

materialdif.com