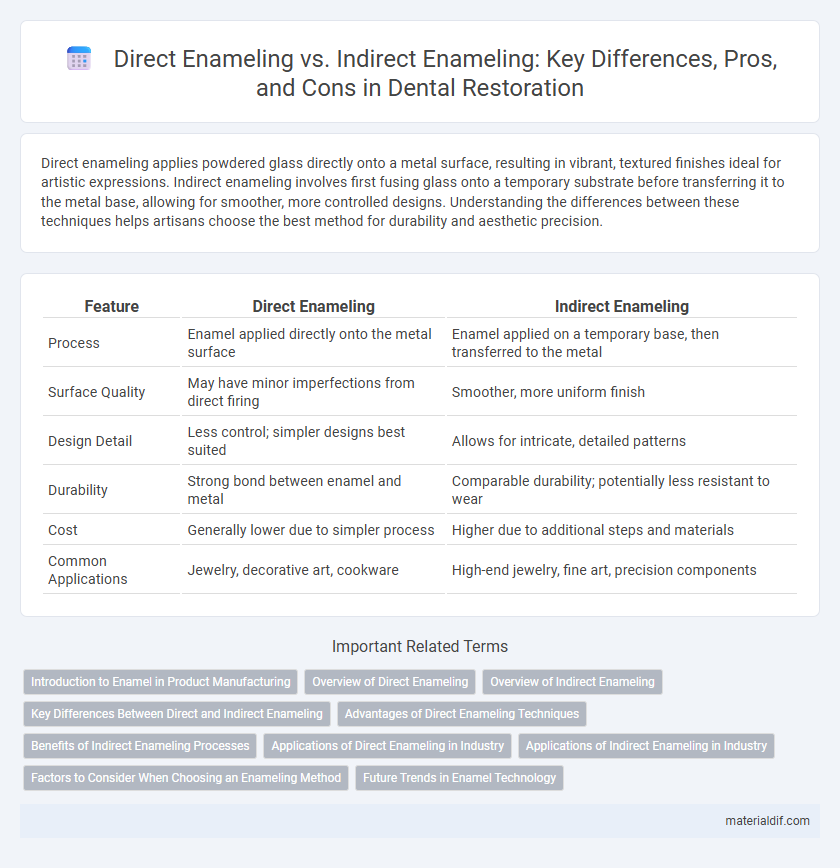

Direct enameling applies powdered glass directly onto a metal surface, resulting in vibrant, textured finishes ideal for artistic expressions. Indirect enameling involves first fusing glass onto a temporary substrate before transferring it to the metal base, allowing for smoother, more controlled designs. Understanding the differences between these techniques helps artisans choose the best method for durability and aesthetic precision.

Table of Comparison

| Feature | Direct Enameling | Indirect Enameling |

|---|---|---|

| Process | Enamel applied directly onto the metal surface | Enamel applied on a temporary base, then transferred to the metal |

| Surface Quality | May have minor imperfections from direct firing | Smoother, more uniform finish |

| Design Detail | Less control; simpler designs best suited | Allows for intricate, detailed patterns |

| Durability | Strong bond between enamel and metal | Comparable durability; potentially less resistant to wear |

| Cost | Generally lower due to simpler process | Higher due to additional steps and materials |

| Common Applications | Jewelry, decorative art, cookware | High-end jewelry, fine art, precision components |

Introduction to Enamel in Product Manufacturing

Direct enameling involves applying powdered glass directly onto a metal surface and firing it to create a durable, glossy coating commonly used in cookware and jewelry. Indirect enameling uses a prepared enamel sheet or decal that is transferred onto the substrate before firing, allowing for more intricate designs and consistent thickness. Both techniques enhance corrosion resistance and aesthetic appeal, with direct enameling offering more robust adhesion and indirect enameling providing superior detail and uniformity in product manufacturing.

Overview of Direct Enameling

Direct enameling involves applying powdered glass directly onto a metal surface, which is then fired at high temperatures to create a smooth, durable coating. This technique allows for vibrant color blending and intricate designs, making it ideal for artistic and decorative applications. The process ensures strong adhesion between the enamel and metal, enhancing durability and resistance to wear and corrosion.

Overview of Indirect Enameling

Indirect enameling involves applying powdered glass onto a temporary surface before fusing it onto the final metal substrate through high-temperature firing. This technique allows for intricate designs and multiple firings without compromising the metal base, commonly used in decorative art and jewelry. It offers greater control over color layering and detail compared to direct enameling, enhancing durability and aesthetic quality.

Key Differences Between Direct and Indirect Enameling

Direct enameling involves applying powdered glass directly onto a metal surface, creating a strong bond through heating that results in vibrant, durable finishes. Indirect enameling uses a transfer process where the design is first applied onto a substrate and then fused onto the metal, allowing more intricate patterns and layered effects. Key differences include the application method, color precision, and the level of detail achievable, with direct enameling offering robust surface adhesion and indirect enameling enabling complex designs.

Advantages of Direct Enameling Techniques

Direct enameling offers superior precision and vibrant color retention due to the direct application of enamel onto the metal surface, enhancing durability and aesthetic appeal. This technique minimizes the risk of imperfections such as bubbles or cracks, resulting in a smoother, more uniform finish. Enhanced control over thickness and texture in direct enameling contributes to its preference in high-quality decorative and industrial applications.

Benefits of Indirect Enameling Processes

Indirect enameling offers superior precision and consistency in color application, ensuring vibrant and uniform finishes on complex surfaces. This method reduces defects such as bubbles and uneven layering, enhancing durability and aesthetic quality. It also allows for more intricate designs by enabling multiple color overlays without compromising the enamel's adhesion or brilliance.

Applications of Direct Enameling in Industry

Direct enameling is extensively used in the manufacturing of cookware, electrical components, and signage due to its strong adhesion and vibrant color retention on metal surfaces. This technique allows for durable, heat-resistant coatings ideal for kitchen appliances and automotive parts exposed to high temperatures. Industrial applications benefit from direct enameling's ability to create corrosion-resistant and aesthetically appealing finishes on steel and cast iron products.

Applications of Indirect Enameling in Industry

Indirect enameling finds extensive applications in the jewelry and decorative arts industries, where intricate designs and high precision are essential. Its ability to produce smooth, detailed surfaces without direct exposure to heat makes it ideal for delicate items and multi-colored patterns. This technique is also favored in industrial components requiring durable, corrosion-resistant coatings with fine artistic finishes.

Factors to Consider When Choosing an Enameling Method

When deciding between direct enameling and indirect enameling, factors such as the complexity of the design, desired durability, and type of substrate play crucial roles. Direct enameling allows for vibrant, thick coatings ideal for intricate patterns, while indirect enameling offers greater control and smoother finishes suitable for mass production. Consider also the firing temperature and enamel composition compatibility to ensure optimal adhesion and longevity.

Future Trends in Enamel Technology

Direct enameling offers superior durability and vibrant colors by applying powdered glass directly to metal substrates, while indirect enameling allows for intricate designs through stencil or screen printing on transfer paper before firing. Emerging trends in enamel technology focus on eco-friendly materials, enhanced thermal shock resistance, and nano-structured enamel coatings that improve longevity and color stability. Innovations in digital printing and automation are also shaping the future, enabling more precise and customizable enamel applications in industrial and artistic sectors.

Direct Enameling vs Indirect Enameling Infographic

materialdif.com

materialdif.com