Hard enamel and soft enamel differ primarily in their texture and finish; hard enamel is polished flat to create a smooth, glass-like surface, while soft enamel has raised metal edges and recessed enamel that provide a textured feel. Hard enamel is more durable and resistant to scratches, making it ideal for high-quality, long-lasting pins, whereas soft enamel offers a cost-effective option with vibrant color contrasts and greater detail definition. Choosing between hard and soft enamel depends on your preference for texture, durability, and budget.

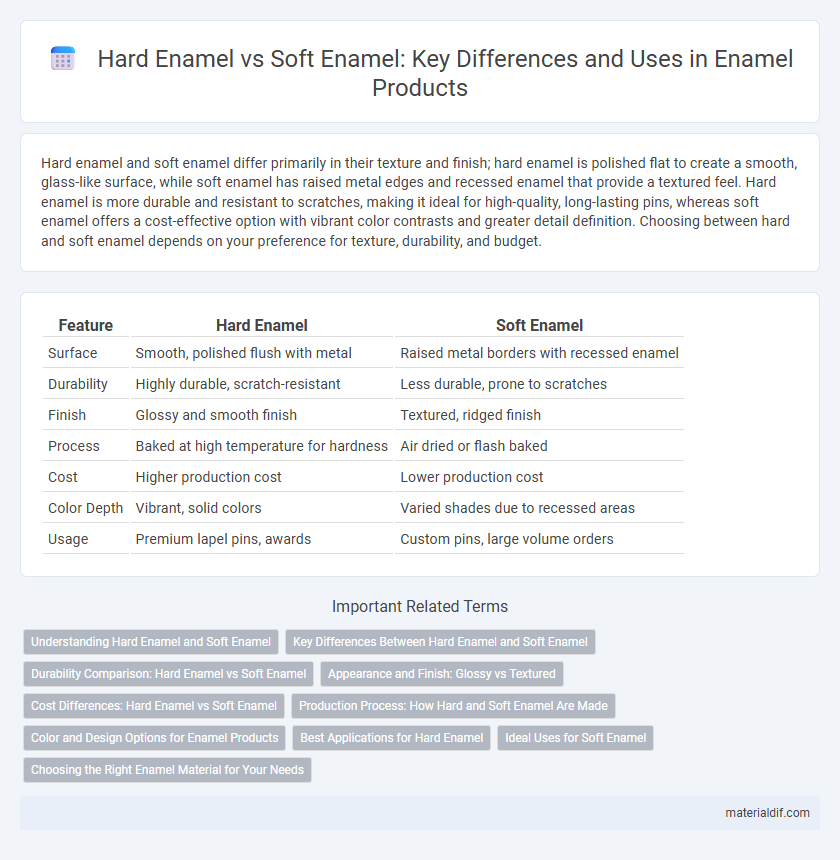

Table of Comparison

| Feature | Hard Enamel | Soft Enamel |

|---|---|---|

| Surface | Smooth, polished flush with metal | Raised metal borders with recessed enamel |

| Durability | Highly durable, scratch-resistant | Less durable, prone to scratches |

| Finish | Glossy and smooth finish | Textured, ridged finish |

| Process | Baked at high temperature for hardness | Air dried or flash baked |

| Cost | Higher production cost | Lower production cost |

| Color Depth | Vibrant, solid colors | Varied shades due to recessed areas |

| Usage | Premium lapel pins, awards | Custom pins, large volume orders |

Understanding Hard Enamel and Soft Enamel

Hard enamel features a smooth, polished surface achieved by filling recessed areas with colored enamel and then baking it at high temperatures, resulting in a durable, glass-like finish ideal for high-quality lapel pins. Soft enamel creates raised metal lines with recessed enamel areas, offering textured designs and a slightly rough surface due to the enamel sitting lower than the metal borders. Understanding the differences helps in choosing hard enamel for a sleek, professional look or soft enamel for vibrant, tactile pins with detailed dimension.

Key Differences Between Hard Enamel and Soft Enamel

Hard enamel features a polished, smooth surface with a glass-like finish, making it more durable and resistant to scratches compared to soft enamel, which has a textured and raised metal outline. Soft enamel fills color recessed areas, creating a noticeable depth difference, whereas hard enamel is filled flush and polished flat for a sleek appearance. The manufacturing process of hard enamel involves firing at higher temperatures to fuse the enamel to the metal base, whereas soft enamel uses air drying or UV curing for a quicker finish.

Durability Comparison: Hard Enamel vs Soft Enamel

Hard enamel offers superior durability compared to soft enamel, making it highly resistant to scratches and wear due to its polished, glass-like finish. Soft enamel, while less durable, provides textured surfaces with raised metal edges, which can wear down over time under frequent use. Choosing hard enamel ensures long-lasting vibrancy and protection, ideal for items exposed to significant handling.

Appearance and Finish: Glossy vs Textured

Hard enamel showcases a smooth, glossy finish achieved by polishing multiple layers until flush with the metal backing, creating a sleek and refined appearance. Soft enamel features recessed areas filled with enamel, leaving raised metal lines that produce a textured, dimensional effect often preferred for intricate designs. The choice between hard and soft enamel significantly influences the visual depth and tactile quality of the finished product.

Cost Differences: Hard Enamel vs Soft Enamel

Hard enamel costs more than soft enamel due to its durable, glass-like finish that requires multiple heating and polishing processes. Soft enamel is more affordable because it involves fewer production steps and air-dried coloring, resulting in a textured finish. Budget-conscious buyers often prefer soft enamel for its cost-efficiency while collectors favor hard enamel for longevity and premium appearance.

Production Process: How Hard and Soft Enamel Are Made

Hard enamel is created by filling recessed areas of a metal pin with colored glass powder, which is then fired at high temperatures, causing the powder to melt and fuse into a smooth, durable surface level with the metal borders. Soft enamel involves filling the recessed areas with enamel paint that is air-dried or baked at lower temperatures, leaving raised metal edges that add texture and depth to the design. The distinct production processes result in hard enamel pins having a polished, flat finish, while soft enamel pins exhibit a more textured, embossed appearance.

Color and Design Options for Enamel Products

Hard enamel offers a smooth, polished finish with colors that are baked at a high temperature, resulting in a durable, glass-like surface ideal for intricate and long-lasting designs. Soft enamel allows for more vibrant color contrasts and raised metal edges, providing textured effects that enhance detailed artwork and create a tactile experience. Both options cater to diverse design needs, with hard enamel favoring sleek, professional looks and soft enamel emphasizing vivid colors and depth.

Best Applications for Hard Enamel

Hard enamel, also known as cloisonne, is best suited for high-quality lapel pins, jewelry, and medals that require a smooth, durable surface with a glass-like finish. Its ability to withstand wear and maintain color vibrancy makes it ideal for items subjected to frequent handling or outdoor exposure. This makes hard enamel the preferred choice for premium collectibles and corporate awards where longevity and detailed design are paramount.

Ideal Uses for Soft Enamel

Soft enamel is ideal for promotional products, lapel pins, and badges due to its textured, recessed design that highlights intricate details and vibrant colors. Its raised metal borders provide durability and a classic look, making it suitable for items requiring affordability and quick production. Soft enamel's ability to combine visual depth with cost-effectiveness makes it perfect for mass-produced merchandise and branded giveaways.

Choosing the Right Enamel Material for Your Needs

Hard enamel offers a smooth, durable finish ideal for high-end lapel pins and jewelry, providing a glassy surface that resists scratches and fading over time. Soft enamel, distinguished by its raised metal borders and recessed enamel areas, delivers vibrant colors and a textured feel, making it perfect for bold designs and cost-effective custom branding. Selecting the right enamel material depends on the desired finish, budget, and usage, with hard enamel best for polished, long-lasting pieces and soft enamel favored for detailed, affordable options.

Hard Enamel vs Soft Enamel Infographic

materialdif.com

materialdif.com