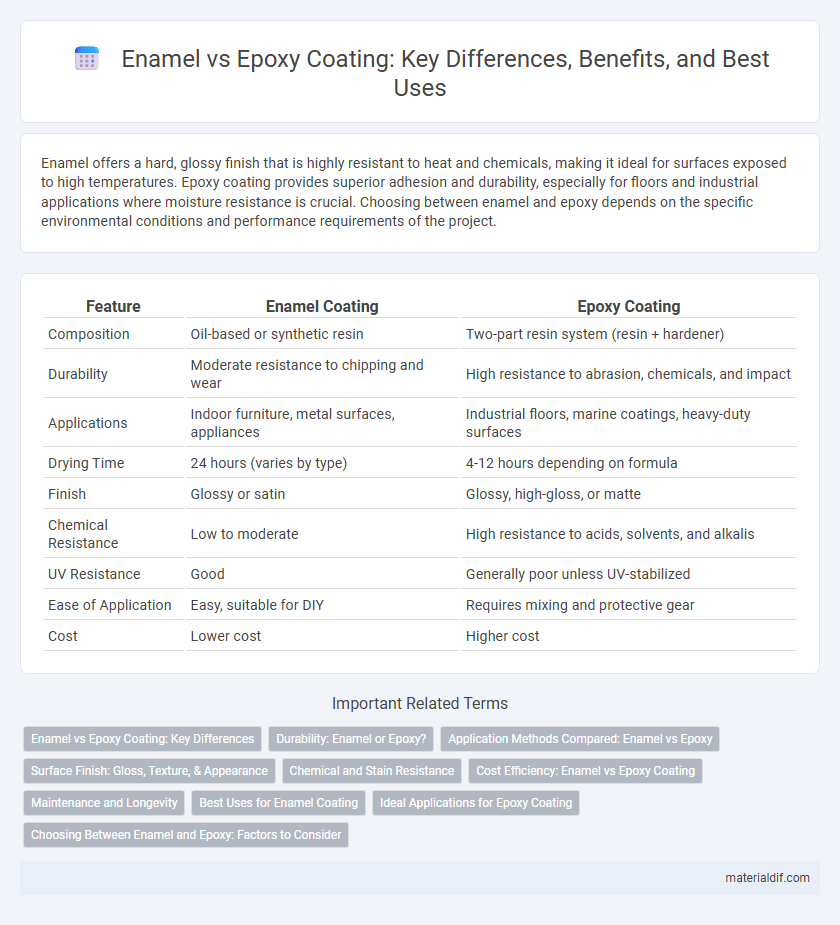

Enamel offers a hard, glossy finish that is highly resistant to heat and chemicals, making it ideal for surfaces exposed to high temperatures. Epoxy coating provides superior adhesion and durability, especially for floors and industrial applications where moisture resistance is crucial. Choosing between enamel and epoxy depends on the specific environmental conditions and performance requirements of the project.

Table of Comparison

| Feature | Enamel Coating | Epoxy Coating |

|---|---|---|

| Composition | Oil-based or synthetic resin | Two-part resin system (resin + hardener) |

| Durability | Moderate resistance to chipping and wear | High resistance to abrasion, chemicals, and impact |

| Applications | Indoor furniture, metal surfaces, appliances | Industrial floors, marine coatings, heavy-duty surfaces |

| Drying Time | 24 hours (varies by type) | 4-12 hours depending on formula |

| Finish | Glossy or satin | Glossy, high-gloss, or matte |

| Chemical Resistance | Low to moderate | High resistance to acids, solvents, and alkalis |

| UV Resistance | Good | Generally poor unless UV-stabilized |

| Ease of Application | Easy, suitable for DIY | Requires mixing and protective gear |

| Cost | Lower cost | Higher cost |

Enamel vs Epoxy Coating: Key Differences

Enamel coatings offer a hard, glossy finish that is typically more resistant to UV rays and weathering than epoxy coatings, making them ideal for exterior surfaces. Epoxy coatings provide superior chemical resistance and adhesion, often used for industrial applications and flooring due to their durability and resistance to abrasion. Unlike epoxy, enamel cures by oxidation and tends to be more flexible but less resistant to solvents and impact damage.

Durability: Enamel or Epoxy?

Epoxy coatings offer superior durability compared to enamel, with high resistance to chemicals, abrasion, and moisture, making them ideal for industrial and heavy-use applications. Enamel provides a hard, glossy finish but tends to chip and wear faster under heavy stress or exposure to harsh environments. For long-term protection and resilience, epoxy coatings generally outperform enamel in durability.

Application Methods Compared: Enamel vs Epoxy

Enamel coatings are typically applied using brushes, rollers, or spray guns, offering easy application with good flow and leveling properties ideal for detailed surfaces. Epoxy coatings require more precise surface preparation and are primarily applied via roller or airless spray, ensuring thicker, durable layers that excel in chemical and abrasion resistance. Differences in curing times and environmental sensitivity also influence the choice of application method between enamel and epoxy coatings.

Surface Finish: Gloss, Texture, & Appearance

Enamel coatings offer a smooth, glossy surface finish with a hard, durable texture that resists chipping and scratches, making them ideal for decorative and protective applications. Epoxy coatings typically provide a thicker, high-gloss, and chemically resistant finish with a tougher texture suited for industrial and high-wear environments. The appearance of enamel is often more vibrant and glossy, while epoxy coatings can vary from matte to high gloss depending on formulation, emphasizing durability over aesthetic detail.

Chemical and Stain Resistance

Enamel coatings exhibit superior chemical resistance due to their hard, glass-like surface, making them highly effective at resisting acids, alkalis, and solvents. Epoxy coatings offer exceptional stain resistance and strong adhesion to various substrates, providing durable protection against oils, grease, and chemicals. While enamel is preferred for its glossy finish and hardness, epoxy's chemical resistance qualities are advantageous in industrial and high-impact environments.

Cost Efficiency: Enamel vs Epoxy Coating

Enamel coatings typically offer a lower initial cost compared to epoxy coatings, making them a cost-efficient choice for projects with tight budgets. Epoxy coatings provide superior durability and chemical resistance, leading to longer service life and reduced maintenance expenses over time. Evaluating total lifecycle costs, epoxy coatings often prove more economical despite higher upfront prices due to enhanced performance and longevity.

Maintenance and Longevity

Enamel coatings offer superior resistance to scratches and chemical wear, making maintenance simpler with only occasional cleaning needed to preserve their glossy finish. Epoxy coatings provide excellent adhesion and durability but may require more frequent touch-ups due to potential yellowing and chipping over time. The longevity of enamel typically exceeds epoxy in high-traffic environments, thanks to its hard, non-porous surface that resists environmental degradation.

Best Uses for Enamel Coating

Enamel coating excels in applications requiring a durable, glossy finish resistant to moisture, chemicals, and abrasion, making it ideal for household appliances, automotive parts, and metal furniture. Its fast-drying properties and superior adhesion to metal surfaces ensure long-lasting protection and aesthetic appeal in indoor environments. Compared to epoxy coatings, enamel is better suited for decorative purposes and surfaces exposed to moderate wear rather than heavy industrial use.

Ideal Applications for Epoxy Coating

Epoxy coating is ideal for high-traffic industrial floors, garage surfaces, and commercial environments due to its exceptional durability, chemical resistance, and strong adhesive properties. Its ability to create a thick, protective barrier makes it suitable for areas exposed to heavy wear and moisture. Epoxy coating is also preferred for its fast curing time and compatibility with various substrates like concrete and metal.

Choosing Between Enamel and Epoxy: Factors to Consider

Choosing between enamel and epoxy coatings depends on factors such as durability, application surface, and environmental exposure. Enamel coatings offer a glossy finish and moderate resistance to wear, making them suitable for indoor furniture and appliances. Epoxy coatings provide superior chemical and abrasion resistance, ideal for industrial floors and outdoor surfaces subject to harsh conditions.

Enamel vs Epoxy Coating Infographic

materialdif.com

materialdif.com