Silica enamel offers superior hardness and chemical resistance, making it ideal for industrial applications requiring durability and corrosion protection. Feldspar enamel, on the other hand, provides enhanced thermal stability and a smoother surface finish, suitable for decorative and household items. Choosing between silica and feldspar enamels depends on the required balance between mechanical strength and aesthetic quality.

Table of Comparison

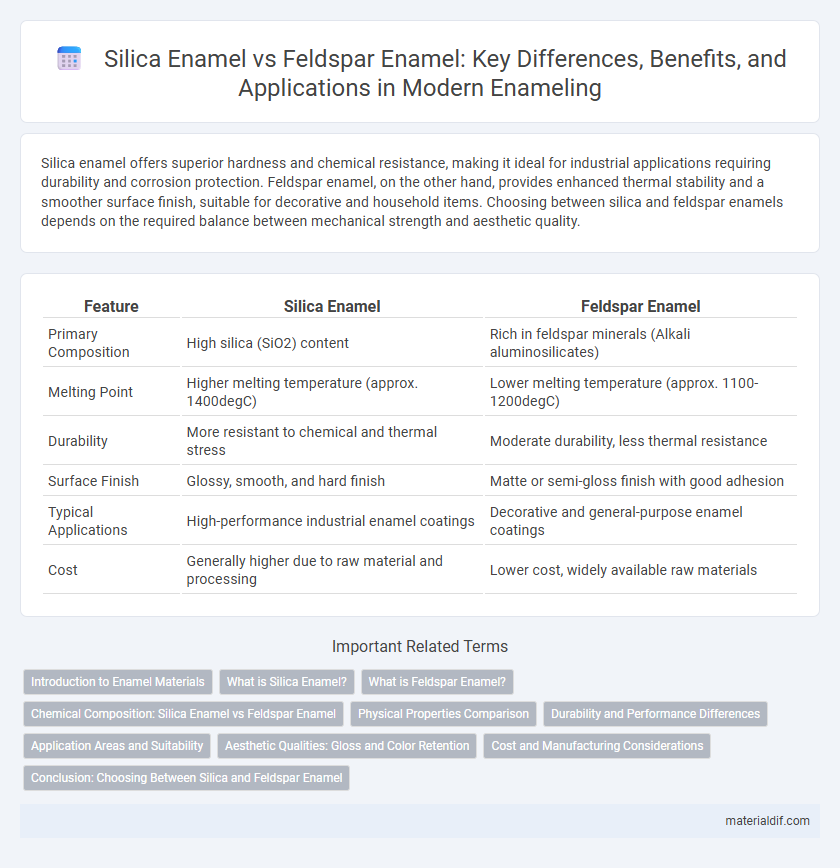

| Feature | Silica Enamel | Feldspar Enamel |

|---|---|---|

| Primary Composition | High silica (SiO2) content | Rich in feldspar minerals (Alkali aluminosilicates) |

| Melting Point | Higher melting temperature (approx. 1400degC) | Lower melting temperature (approx. 1100-1200degC) |

| Durability | More resistant to chemical and thermal stress | Moderate durability, less thermal resistance |

| Surface Finish | Glossy, smooth, and hard finish | Matte or semi-gloss finish with good adhesion |

| Typical Applications | High-performance industrial enamel coatings | Decorative and general-purpose enamel coatings |

| Cost | Generally higher due to raw material and processing | Lower cost, widely available raw materials |

Introduction to Enamel Materials

Silica enamel primarily consists of silicon dioxide, offering high thermal stability and excellent resistance to chemical corrosion, making it ideal for industrial applications. Feldspar enamel incorporates potassium aluminum silicate, providing enhanced durability, smooth finish, and better adherence to metal substrates. Both enamel materials serve distinct purposes in coating technologies, with silica favored for heat resistance and feldspar preferred for aesthetic and protective finishes.

What is Silica Enamel?

Silica enamel is a glassy coating composed primarily of silicon dioxide (SiO2), known for its high thermal resistance, durability, and chemical stability, making it ideal for protective and decorative applications. Unlike feldspar enamel, which contains alkali aluminosilicates, silica enamel offers superior resistance to acidic environments and extreme temperatures. This enamel type is widely used in cookware, industrial equipment, and architectural surfaces due to its robust bonding properties and long-lasting finish.

What is Feldspar Enamel?

Feldspar enamel is a type of glassy coating made primarily from feldspar minerals, which serve as a crucial flux in the enamel formulation, lowering the melting point and enhancing durability. Compared to silica enamel, feldspar enamel offers superior chemical resistance and a smoother surface finish, making it ideal for applications requiring both aesthetic appeal and long-lasting protection. Its unique mineral composition, rich in potassium and sodium aluminosilicates, contributes to improved adhesion on metal substrates and increased resistance to thermal shock.

Chemical Composition: Silica Enamel vs Feldspar Enamel

Silica enamel primarily contains high levels of silicon dioxide (SiO2), which enhances its hardness and chemical resistance, making it suitable for industrial applications requiring durability. Feldspar enamel incorporates significant amounts of potassium aluminum silicates (KAlSi3O8) that improve thermal stability and facilitate smoother melting behavior during firing. The distinct chemical compositions directly influence enamel performance characteristics such as adhesion, thermal expansion, and resistance to corrosion.

Physical Properties Comparison

Silica enamel exhibits higher hardness and better thermal stability compared to feldspar enamel, making it more resistant to abrasion and temperature fluctuations. Feldspar enamel offers superior gloss and smoother texture due to its lower melting point and increased flux content. Both types demonstrate excellent chemical durability, but silica enamel generally outperforms feldspar enamel in mechanical strength and resistance to thermal shock.

Durability and Performance Differences

Silica enamel offers superior chemical resistance and thermal stability compared to feldspar enamel, making it highly durable in high-temperature and corrosive environments. Feldspar enamel, while providing good mechanical strength and smooth finish, tends to be less resistant to chemical wear and thermal shock. These performance differences influence the selection of enamel types in applications requiring enhanced longevity and resistance.

Application Areas and Suitability

Silica enamel offers excellent chemical resistance and high-temperature stability, making it ideal for industrial applications such as chemical reactors and furnace linings. Feldspar enamel provides superior mechanical strength and a glossy finish, often used in consumer goods like cookware and decorative ceramics. Choosing between silica and feldspar enamel depends on the required durability, aesthetic quality, and exposure conditions of the final product.

Aesthetic Qualities: Gloss and Color Retention

Silica enamel offers superior gloss retention due to its high silica content, which creates a smooth, reflective surface that enhances visual appeal over time. Feldspar enamel delivers vibrant color stability, as its potassium-rich composition resists fading under prolonged exposure to sunlight and heat. The combination of silica's glossy finish and feldspar's durable pigmentation makes each enamel type uniquely suited for specific aesthetic applications in ceramics and glassware.

Cost and Manufacturing Considerations

Silica enamel presents a cost-effective option due to its lower raw material expenses and simpler manufacturing process compared to feldspar enamel, which requires more precise temperature control and higher-quality raw materials. Feldspar enamel typically demands advanced kiln technology and longer firing times, increasing energy consumption and production costs. Manufacturers must balance these factors against desired enamel properties, with silica enamel favored for budget-sensitive applications and feldspar enamel chosen for superior durability and finish quality.

Conclusion: Choosing Between Silica and Feldspar Enamel

Silica enamel offers superior hardness and chemical resistance, making it ideal for industrial applications requiring durability and corrosion protection. Feldspar enamel provides better thermal shock resistance and a smoother finish, suited for decorative and cookware purposes. Selecting between silica and feldspar enamel depends on the specific performance needs, balancing hardness versus thermal stability.

Silica enamel vs Feldspar enamel Infographic

materialdif.com

materialdif.com