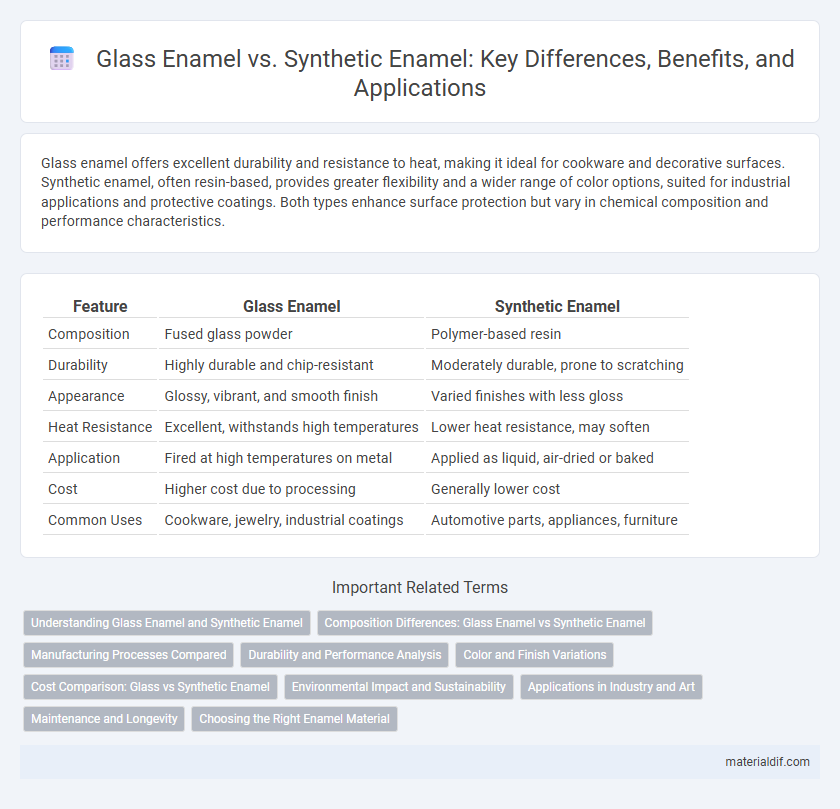

Glass enamel offers excellent durability and resistance to heat, making it ideal for cookware and decorative surfaces. Synthetic enamel, often resin-based, provides greater flexibility and a wider range of color options, suited for industrial applications and protective coatings. Both types enhance surface protection but vary in chemical composition and performance characteristics.

Table of Comparison

| Feature | Glass Enamel | Synthetic Enamel |

|---|---|---|

| Composition | Fused glass powder | Polymer-based resin |

| Durability | Highly durable and chip-resistant | Moderately durable, prone to scratching |

| Appearance | Glossy, vibrant, and smooth finish | Varied finishes with less gloss |

| Heat Resistance | Excellent, withstands high temperatures | Lower heat resistance, may soften |

| Application | Fired at high temperatures on metal | Applied as liquid, air-dried or baked |

| Cost | Higher cost due to processing | Generally lower cost |

| Common Uses | Cookware, jewelry, industrial coatings | Automotive parts, appliances, furniture |

Understanding Glass Enamel and Synthetic Enamel

Glass enamel, also known as vitreous enamel, is a smooth, durable coating made by fusing powdered glass to a substrate through high-temperature firing, offering excellent resistance to heat, chemicals, and corrosion. Synthetic enamel, typically composed of resin-based polymers, provides a flexible, quick-drying finish that is ideal for industrial applications requiring impact resistance and less heat exposure. Understanding the differences in composition, application methods, and performance properties is crucial for selecting the appropriate enamel type in manufacturing and design projects.

Composition Differences: Glass Enamel vs Synthetic Enamel

Glass enamel consists primarily of finely ground glass particles fused onto a substrate through high-temperature firing, creating a durable, glossy surface with excellent chemical resistance. Synthetic enamel, on the other hand, is typically formulated from polymer resins combined with pigments and additives, curing at lower temperatures to form a flexible, impact-resistant coating. The key composition difference lies in the inorganic silica-base of glass enamel versus the organic polymer base of synthetic enamel, influencing their application methods and performance characteristics.

Manufacturing Processes Compared

Glass enamel manufacturing involves fusing powdered glass to a metal substrate through high-temperature firing, creating a durable, smooth coating with excellent chemical and heat resistance. Synthetic enamel, often composed of polymer-based resins, is applied via spraying or dipping and cured at lower temperatures, offering faster production cycles but reduced heat tolerance. The firing process in glass enameling requires precise temperature control, while synthetic enamel manufacturing emphasizes formulation adjustments for environmental compliance and flexibility in application methods.

Durability and Performance Analysis

Glass enamel offers superior durability due to its resistance to scratches, heat, and chemicals, making it ideal for high-wear applications and long-term use. Synthetic enamel, while more affordable and versatile in terms of color and finish, generally exhibits lower resistance to environmental factors, leading to faster wear and potential degradation. Performance analysis reveals glass enamel's enhanced longevity and structural integrity, whereas synthetic enamel provides easier application and quicker drying times, suited for less demanding surfaces.

Color and Finish Variations

Glass enamel offers rich, vibrant color depth and a glossy finish with high durability, making it ideal for artistic and decorative applications. Synthetic enamel provides a broader range of color options with customizable matte, satin, and gloss finishes, allowing for versatile surface textures and enhanced adaptability in industrial uses. Both enamel types exhibit excellent adhesion and resistance, but synthetic enamel allows for finer control over finish variations through chemical composition adjustments.

Cost Comparison: Glass vs Synthetic Enamel

Glass enamel typically incurs higher production costs due to its raw material composition and energy-intensive firing process, while synthetic enamel benefits from lower manufacturing expenses and faster curing times. The cost efficiency of synthetic enamel makes it a preferred choice for large-scale industrial applications where budget constraints are critical. However, glass enamel's superior durability and resistance to thermal shock may justify its premium price in high-performance or decorative uses.

Environmental Impact and Sustainability

Glass enamel demonstrates superior environmental sustainability due to its natural composition of silica, soda ash, and limestone, making it non-toxic and fully recyclable with minimal pollution during production. Synthetic enamel often contains volatile organic compounds (VOCs) and heavy metals, which contribute to environmental degradation and pose challenges in waste management. Choosing glass enamel over synthetic options significantly reduces carbon footprint and supports eco-friendly manufacturing practices.

Applications in Industry and Art

Glass enamel exhibits superior durability and heat resistance, making it ideal for industrial applications such as cookware, automotive parts, and architectural panels. Synthetic enamel offers greater color variety and faster curing times, preferred in artistic works like jewelry, decorative objects, and fine art paintings. Both types provide corrosion protection and aesthetic enhancement, but the choice depends on specific industry requirements and artistic expression.

Maintenance and Longevity

Glass enamel offers superior durability and resistance to scratching, making it easier to maintain with minimal upkeep and preserving its glossy finish for decades. Synthetic enamel, while more affordable, tends to wear down faster and may require frequent touch-ups to maintain appearance and protection. The inherent hardness of glass enamel ensures longer lifespan and resilience against environmental factors compared to synthetic alternatives.

Choosing the Right Enamel Material

Glass enamel offers superior durability and a natural, glossy finish that is highly resistant to heat, chemicals, and weathering, making it ideal for outdoor applications and cookware. Synthetic enamel, often epoxy or acrylic-based, provides greater flexibility in color options and faster curing times, suitable for indoor decorative pieces and items requiring rapid production. Selecting the right enamel material depends on the intended use, environmental exposure, and desired aesthetic, with glass enamel favored for longevity and synthetic enamel for versatility and ease of application.

Glass enamel vs Synthetic enamel Infographic

materialdif.com

materialdif.com