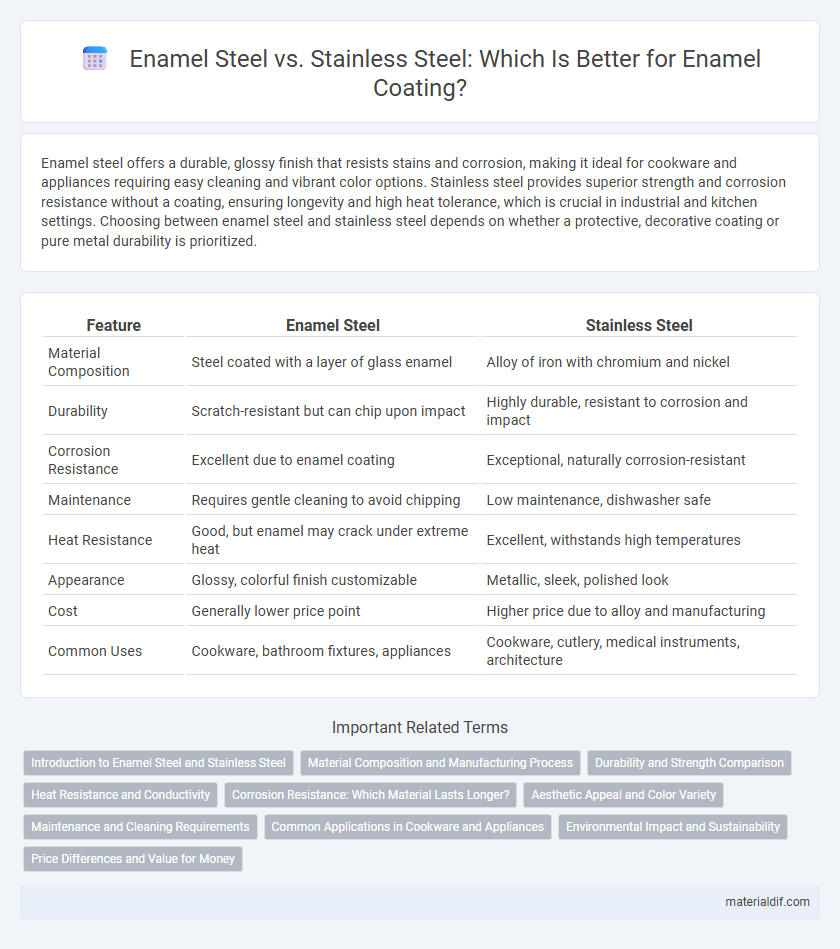

Enamel steel offers a durable, glossy finish that resists stains and corrosion, making it ideal for cookware and appliances requiring easy cleaning and vibrant color options. Stainless steel provides superior strength and corrosion resistance without a coating, ensuring longevity and high heat tolerance, which is crucial in industrial and kitchen settings. Choosing between enamel steel and stainless steel depends on whether a protective, decorative coating or pure metal durability is prioritized.

Table of Comparison

| Feature | Enamel Steel | Stainless Steel |

|---|---|---|

| Material Composition | Steel coated with a layer of glass enamel | Alloy of iron with chromium and nickel |

| Durability | Scratch-resistant but can chip upon impact | Highly durable, resistant to corrosion and impact |

| Corrosion Resistance | Excellent due to enamel coating | Exceptional, naturally corrosion-resistant |

| Maintenance | Requires gentle cleaning to avoid chipping | Low maintenance, dishwasher safe |

| Heat Resistance | Good, but enamel may crack under extreme heat | Excellent, withstands high temperatures |

| Appearance | Glossy, colorful finish customizable | Metallic, sleek, polished look |

| Cost | Generally lower price point | Higher price due to alloy and manufacturing |

| Common Uses | Cookware, bathroom fixtures, appliances | Cookware, cutlery, medical instruments, architecture |

Introduction to Enamel Steel and Stainless Steel

Enamel steel is carbon steel coated with a smooth, durable layer of glass-like enamel, providing excellent resistance to corrosion, wear, and chemicals, making it ideal for cookware and industrial applications. Stainless steel, an alloy primarily composed of iron, chromium, and nickel, offers high corrosion resistance, strength, and durability without additional coatings. Both materials serve diverse functions, with enamel steel combining aesthetic appeal and protection, while stainless steel emphasizes structural integrity and resistance to rust.

Material Composition and Manufacturing Process

Enamel steel consists of a carbon steel base coated with a layer of glass-like enamel, created through a process of firing powdered glass at high temperatures to fuse it onto the steel surface, offering excellent corrosion resistance and vibrant color options. Stainless steel is an alloy primarily composed of iron, chromium (at least 10.5%), and sometimes nickel and molybdenum, produced by melting and casting processes followed by cold working or annealing to enhance strength and corrosion resistance through the formation of a passive oxide layer. The enamel coating in enamel steel provides a harder, scratch-resistant surface, while stainless steel's corrosion resistance is intrinsic due to its alloy composition and microstructure.

Durability and Strength Comparison

Enamel steel offers superior corrosion resistance due to its glass-like coating, making it highly durable against rust and chemical damage compared to stainless steel. Stainless steel boasts higher tensile strength and impact resistance, providing enhanced structural integrity for heavy-duty applications. While enamel steel excels in surface protection and longevity in harsh environments, stainless steel is preferable for mechanical strength and flexibility.

Heat Resistance and Conductivity

Enamel steel offers superior heat resistance compared to stainless steel, maintaining structural integrity under higher temperatures without warping or discoloration. Stainless steel, while less heat-resistant, provides excellent thermal conductivity, allowing for quicker and more even heat distribution in cooking applications. Choosing between enamel steel and stainless steel depends on whether heat retention or heat conduction is prioritized in the intended use.

Corrosion Resistance: Which Material Lasts Longer?

Enamel steel offers superior corrosion resistance due to its glassy, non-porous coating that prevents rust and chemical damage by sealing the metal surface completely. Stainless steel contains chromium that forms a passive oxide layer to resist rust, but prolonged exposure to harsh environments can cause pitting and corrosion over time. Enamel-coated steel generally lasts longer in corrosive conditions because its protective layer acts as a durable barrier, whereas stainless steel relies on maintaining its oxide film integrity.

Aesthetic Appeal and Color Variety

Enamel steel offers a vibrant color palette and glossy finish that enhances aesthetic appeal, making it ideal for decorative applications and vibrant kitchenware. Stainless steel typically features a sleek, metallic sheen with limited color options, emphasizing modern minimalism and durability. The ability of enamel steel to retain bold colors without fading provides a distinct advantage over the more subdued, natural look of stainless steel.

Maintenance and Cleaning Requirements

Enamel steel requires gentle cleaning with non-abrasive sponges and mild detergents to preserve its glossy, protective coating and prevent chipping or cracking. Stainless steel offers more durability against scratches and stains but demands regular polishing to maintain its corrosion-resistant surface and prevent water spots. Both materials benefit from immediate drying after washing to avoid rust and prolong lifespan.

Common Applications in Cookware and Appliances

Enamel steel is commonly used in cookware such as Dutch ovens, baking dishes, and stovetop pots due to its vibrant finish, ease of cleaning, and resistance to rust and acids. Stainless steel, favored in cookware and appliances like sinks, toaster ovens, and coffee makers, offers superior durability, heat resistance, and non-reactivity with foods. Both materials are popular in kitchen tools, but enamel steel excels in decorative appeal while stainless steel provides long-lasting strength and corrosion resistance.

Environmental Impact and Sustainability

Enamel steel offers a durable, long-lasting surface that reduces the need for frequent replacements, contributing to lower overall resource consumption and waste compared to stainless steel. Stainless steel production involves higher energy consumption and greenhouse gas emissions due to its alloying elements and complex processing. Enamel steel's ability to preserve underlying metal extends product life, enhancing sustainability through reduced environmental footprint across its lifecycle.

Price Differences and Value for Money

Enamel steel typically costs less than stainless steel due to lower production expenses and simpler materials, making it a budget-friendly option for cookware and appliances. Stainless steel offers superior durability, corrosion resistance, and a sleek finish, often justifying its higher price with long-term value and maintenance savings. When balancing price differences, enamel steel provides good value for short-term use, while stainless steel delivers greater longevity and cost-effectiveness over time.

Enamel Steel vs Stainless Steel Infographic

materialdif.com

materialdif.com