Hot-applied enamel offers superior durability and a glossy, smooth finish due to its application at high temperatures, ensuring better adhesion and resistance to chipping. Cold-applied enamel is more convenient for quick touch-ups and small projects, providing easier application without the need for heating equipment, though it typically lacks the long-term resilience of hot-applied enamel. Choosing between the two depends on the specific demands of the project, balancing ease of use with performance requirements.

Table of Comparison

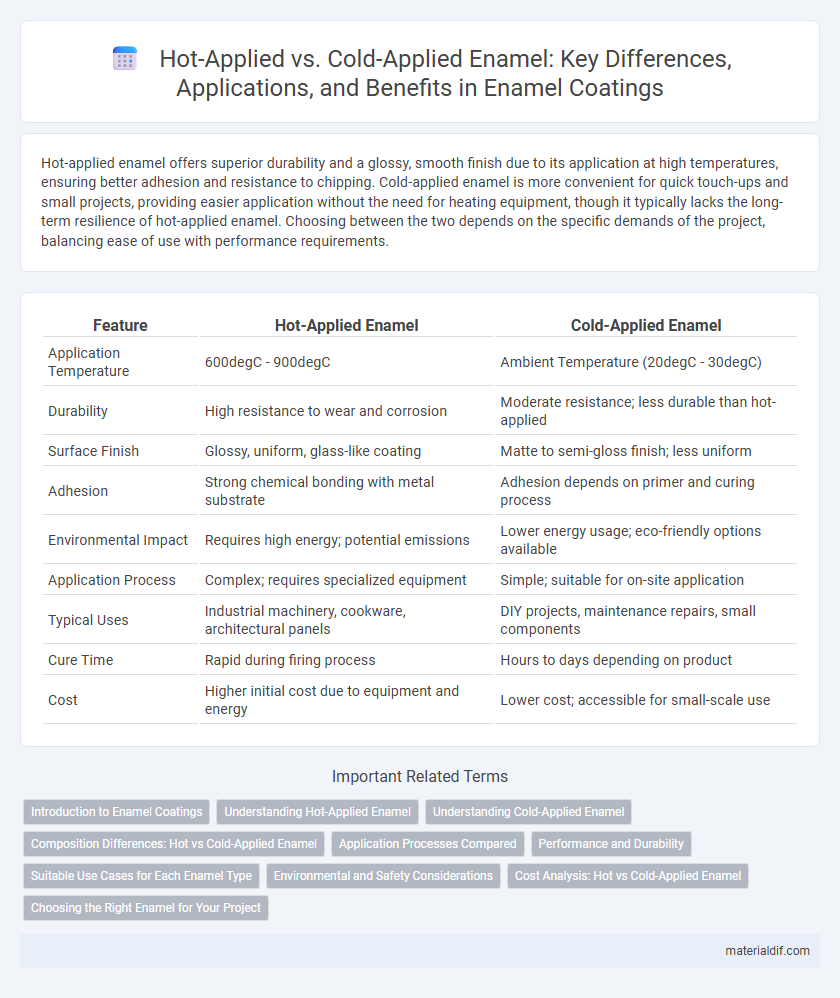

| Feature | Hot-Applied Enamel | Cold-Applied Enamel |

|---|---|---|

| Application Temperature | 600degC - 900degC | Ambient Temperature (20degC - 30degC) |

| Durability | High resistance to wear and corrosion | Moderate resistance; less durable than hot-applied |

| Surface Finish | Glossy, uniform, glass-like coating | Matte to semi-gloss finish; less uniform |

| Adhesion | Strong chemical bonding with metal substrate | Adhesion depends on primer and curing process |

| Environmental Impact | Requires high energy; potential emissions | Lower energy usage; eco-friendly options available |

| Application Process | Complex; requires specialized equipment | Simple; suitable for on-site application |

| Typical Uses | Industrial machinery, cookware, architectural panels | DIY projects, maintenance repairs, small components |

| Cure Time | Rapid during firing process | Hours to days depending on product |

| Cost | Higher initial cost due to equipment and energy | Lower cost; accessible for small-scale use |

Introduction to Enamel Coatings

Hot-applied enamel coatings are applied at elevated temperatures, resulting in a durable, fused layer that offers superior resistance to abrasion and corrosion. Cold-applied enamels, applied at ambient temperatures, provide easier application with quicker drying times but generally offer less durability and chemical resistance. Both types enhance surface protection and aesthetic appeal, with hot-applied enamels typically preferred for heavy-duty industrial uses and cold-applied enamels favored for maintenance and touch-up applications.

Understanding Hot-Applied Enamel

Hot-applied enamel involves applying glass frit at temperatures typically ranging from 760degC to 900degC, ensuring a durable, fused coating with superior resistance to abrasion and chemical corrosion. This process creates a hard, glossy finish that bonds directly to metal substrates, enhancing longevity and protection in industrial applications. The high heat application also allows for increased adhesion strength compared to cold-applied enamel, which relies on air-drying or low-temperature curing methods.

Understanding Cold-Applied Enamel

Cold-applied enamel is a versatile coating method that cures at ambient temperatures, offering easier application on heat-sensitive substrates compared to hot-applied enamel. It comprises pre-formulated resins and pigments that chemically cure without the need for high heat, providing durable corrosion resistance and vibrant color retention. This enamel type is ideal for complex shapes and delicate materials where thermal impact must be minimized.

Composition Differences: Hot vs Cold-Applied Enamel

Hot-applied enamel typically contains a higher concentration of glass frit combined with silica, fluxes, and oxides, which fuse at elevated temperatures to create a durable, glossy coating. Cold-applied enamel consists mainly of finely ground glass powders suspended in an organic binder, allowing application at room temperature but requiring curing or firing to achieve hardness. The primary compositional difference lies in the thermal stability and particle size of the glass components, affecting adhesion, finish quality, and application methods.

Application Processes Compared

Hot-applied enamel involves heating the enamel to a molten state before applying it to the substrate, ensuring strong adhesion and a smooth, durable finish ideal for metal surfaces. Cold-applied enamel, applied at room temperature, uses enamel suspensions or liquid enamels that cure without heating, making it suitable for sensitive materials and complex shapes. The hot-applied process typically requires higher energy and specialized equipment, whereas cold-applied enamel allows for easier, more versatile application with shorter processing times.

Performance and Durability

Hot-applied enamel offers superior performance and durability due to its ability to fuse tightly to metal surfaces, creating a hard, chip-resistant coating that withstands high temperatures and harsh environmental conditions. Cold-applied enamel, while easier to apply and suitable for touch-ups or repairs, typically forms a thinner layer with less resistance to abrasion and chemical exposure. Industrial applications demanding long-term corrosion protection and mechanical strength prefer hot-applied enamel for its enhanced adhesion and longevity.

Suitable Use Cases for Each Enamel Type

Hot-applied enamel is ideal for industrial applications requiring high durability and resistance to extreme temperatures, such as automotive parts, cookware, and architectural elements exposed to harsh weather. Cold-applied enamel offers greater flexibility for arts and crafts, decorative coatings, and touch-up repairs on delicate surfaces where heat exposure is unsuitable. Each enamel type's suitability depends on the substrate, environmental conditions, and intended longevity of the finish.

Environmental and Safety Considerations

Hot-applied enamel involves high-temperature processes that can emit volatile organic compounds (VOCs) and require strict ventilation to mitigate health risks for workers. Cold-applied enamel uses solvent-based or water-based formulations, often resulting in lower energy consumption but potential VOC emissions, requiring careful handling and protective equipment to prevent skin contact and inhalation hazards. Selecting between hot and cold-applied enamel depends on balancing environmental impact, regulatory compliance, and workplace safety protocols.

Cost Analysis: Hot vs Cold-Applied Enamel

Hot-applied enamel generally incurs higher upfront costs due to the energy-intensive heating process and specialized equipment required, but it offers superior adhesion and durability, potentially reducing long-term maintenance expenses. Cold-applied enamel typically has lower initial application costs and faster curing times but may require more frequent touch-ups and recoating, increasing overall lifecycle costs. Evaluating total cost of ownership involves balancing initial investment against performance longevity and maintenance frequency for a precise cost-benefit analysis.

Choosing the Right Enamel for Your Project

Hot-applied enamel offers superior durability and resistance to high temperatures, making it ideal for industrial and automotive applications prone to heat exposure. Cold-applied enamel, in contrast, provides easier application and faster drying times, suitable for small-scale or decorative projects requiring less heat resistance. Selecting the right enamel depends on project requirements such as temperature resilience, surface type, and desired finish longevity.

Hot-applied enamel vs Cold-applied enamel Infographic

materialdif.com

materialdif.com