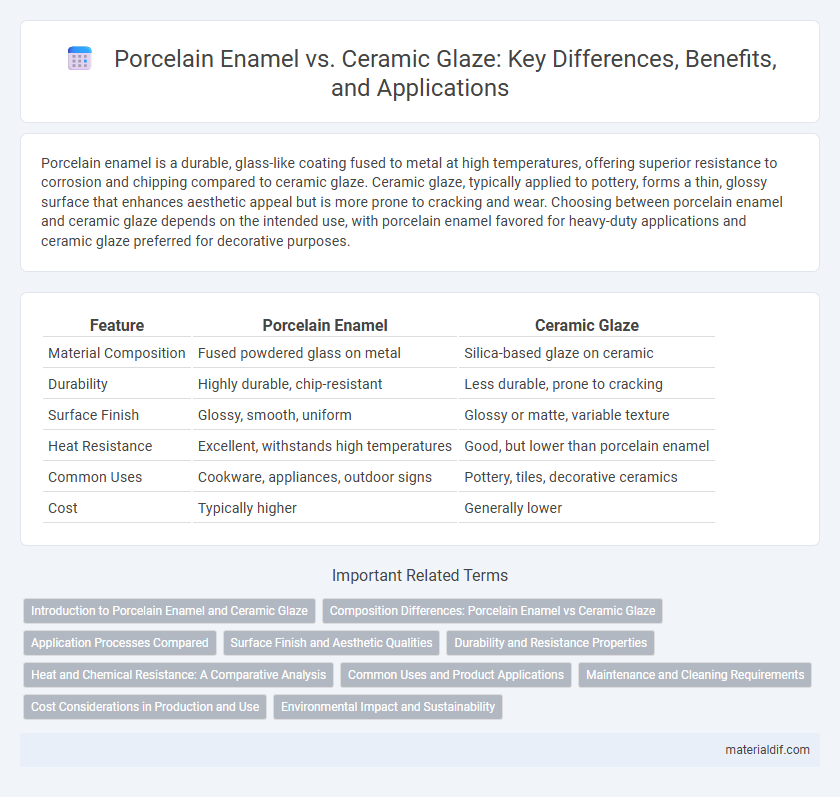

Porcelain enamel is a durable, glass-like coating fused to metal at high temperatures, offering superior resistance to corrosion and chipping compared to ceramic glaze. Ceramic glaze, typically applied to pottery, forms a thin, glossy surface that enhances aesthetic appeal but is more prone to cracking and wear. Choosing between porcelain enamel and ceramic glaze depends on the intended use, with porcelain enamel favored for heavy-duty applications and ceramic glaze preferred for decorative purposes.

Table of Comparison

| Feature | Porcelain Enamel | Ceramic Glaze |

|---|---|---|

| Material Composition | Fused powdered glass on metal | Silica-based glaze on ceramic |

| Durability | Highly durable, chip-resistant | Less durable, prone to cracking |

| Surface Finish | Glossy, smooth, uniform | Glossy or matte, variable texture |

| Heat Resistance | Excellent, withstands high temperatures | Good, but lower than porcelain enamel |

| Common Uses | Cookware, appliances, outdoor signs | Pottery, tiles, decorative ceramics |

| Cost | Typically higher | Generally lower |

Introduction to Porcelain Enamel and Ceramic Glaze

Porcelain enamel, a glassy coating fused onto metal at high temperatures, provides a durable and corrosion-resistant surface often used in cookware and appliances. Ceramic glaze, a vitrified coating applied to ceramic objects, enhances aesthetic appeal and adds a waterproof layer while maintaining the porous nature of the base material. Both materials involve high-temperature firing processes but differ fundamentally in substrate compatibility and functional properties.

Composition Differences: Porcelain Enamel vs Ceramic Glaze

Porcelain enamel consists of powdered glass fused to metal at high temperatures, creating a durable, non-porous coating ideal for cookware and industrial applications. Ceramic glaze is a silica-based glassy coating applied to ceramics, primarily composed of alumina, silica, and fluxes, which vitrify during firing to form a smooth, often decorative, surface. The key composition difference lies in porcelain enamel's metal substrate bonding versus ceramic glaze's adherence to clay-based ceramics, influencing their respective durability and functional uses.

Application Processes Compared

Porcelain enamel involves fusing powdered glass to metal at high temperatures, creating a durable, glass-like coating resistant to corrosion and scratching. Ceramic glaze is applied as a liquid suspension of minerals on pottery and fired at lower temperatures, producing a smooth, often decorative, and waterproof finish. The enamel process requires precise temperature control to bond with metal substrates, while ceramic glazing focuses on aesthetic qualities and surface protection of clay-based materials.

Surface Finish and Aesthetic Qualities

Porcelain enamel offers a smooth, glossy finish that is highly durable and resistant to scratches, ideal for vibrant, long-lasting colors and a sleek appearance. Ceramic glaze tends to have a more varied texture, ranging from matte to glossy, and can showcase a wider palette of earthy or rustic tones with subtle surface imperfections that enhance its artisanal aesthetic. Both finishes provide strong protection but porcelain enamel excels in uniformity and brilliance, while ceramic glaze delivers more unique, handcrafted visual qualities.

Durability and Resistance Properties

Porcelain enamel offers superior durability compared to ceramic glaze due to its vitrified glass coating that bonds permanently to metal surfaces, providing excellent resistance to chipping, scratching, and corrosion. Ceramic glazes, while effective on pottery and tiles, are more prone to cracking and wear under heavy mechanical stress and thermal cycling. The high resistance of porcelain enamel to chemical damage and UV radiation makes it ideal for industrial applications where long-lasting performance is critical.

Heat and Chemical Resistance: A Comparative Analysis

Porcelain enamel offers superior heat resistance, withstanding temperatures up to 1500degF without degradation, compared to ceramic glaze which typically endures up to 1200degF. Chemically, porcelain enamel exhibits higher resistance to acids, alkalis, and solvents due to its vitreous, non-porous surface, reducing corrosion and staining risks. This makes porcelain enamel the preferred choice in industrial applications requiring durable, heat- and chemical-resistant coatings.

Common Uses and Product Applications

Porcelain enamel is commonly used for coating metal surfaces in appliances, cookware, and industrial equipment due to its durability and resistance to corrosion. Ceramic glaze typically serves decorative and protective purposes on pottery, tiles, and architectural ceramics, offering a variety of finishes and colors. Both materials enhance product longevity, but porcelain enamel is preferred for heavy-duty applications, while ceramic glaze excels in aesthetic and functional surface treatments.

Maintenance and Cleaning Requirements

Porcelain enamel offers a durable, non-porous surface that resists stains and requires minimal maintenance compared to ceramic glaze, which can be more porous and prone to chipping. Cleaning porcelain enamel typically involves simple wiping with mild soap and water, avoiding abrasive cleaners that could scratch the surface. Ceramic glaze often needs gentler care and more frequent touch-ups to maintain its glossy finish and prevent damage.

Cost Considerations in Production and Use

Porcelain enamel typically involves higher production costs due to its complex firing process and the use of metal substrates, resulting in durable, corrosion-resistant finishes ideal for cookware and industrial applications. Ceramic glaze tends to be more cost-effective, with simpler application and firing methods suitable for decorative pottery and tiles, but may lack the long-term durability of porcelain enamel. Evaluating these cost factors alongside product requirements helps manufacturers and consumers choose the optimal coating for both budget and performance needs.

Environmental Impact and Sustainability

Porcelain enamel offers superior durability and resistance to chipping compared to ceramic glaze, resulting in longer product lifespans that reduce waste. Ceramic glazes often contain heavy metals and lead, posing environmental risks during production and disposal, whereas modern porcelain enamel formulations are increasingly free from toxic substances. Sustainable manufacturing practices for porcelain enamel include recycling scrap materials and using lower-temperature firing processes, which minimize energy consumption and carbon emissions.

Porcelain Enamel vs Ceramic Glaze Infographic

materialdif.com

materialdif.com