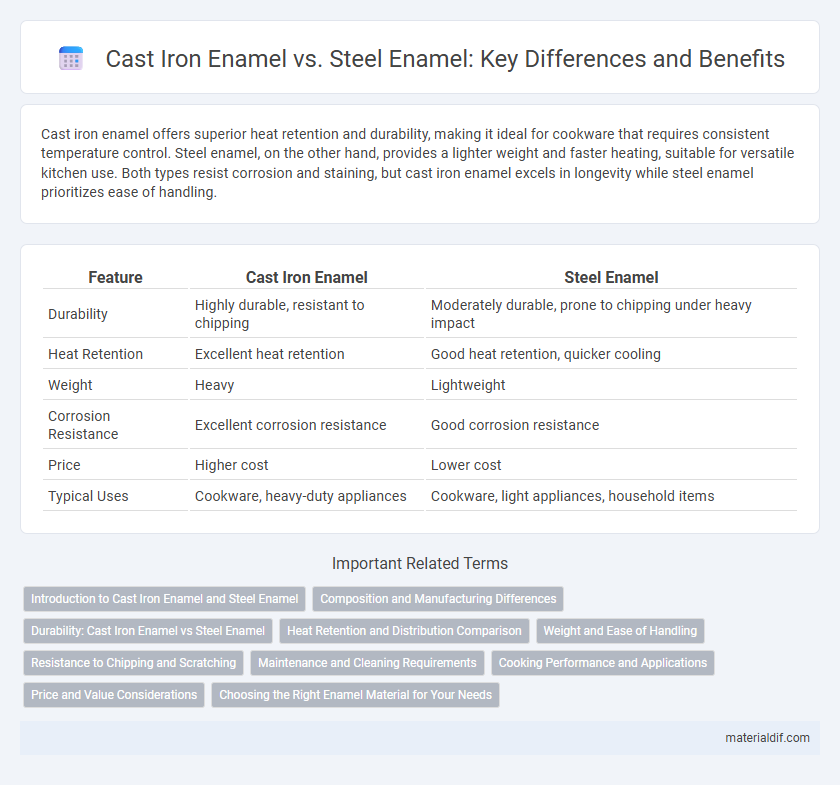

Cast iron enamel offers superior heat retention and durability, making it ideal for cookware that requires consistent temperature control. Steel enamel, on the other hand, provides a lighter weight and faster heating, suitable for versatile kitchen use. Both types resist corrosion and staining, but cast iron enamel excels in longevity while steel enamel prioritizes ease of handling.

Table of Comparison

| Feature | Cast Iron Enamel | Steel Enamel |

|---|---|---|

| Durability | Highly durable, resistant to chipping | Moderately durable, prone to chipping under heavy impact |

| Heat Retention | Excellent heat retention | Good heat retention, quicker cooling |

| Weight | Heavy | Lightweight |

| Corrosion Resistance | Excellent corrosion resistance | Good corrosion resistance |

| Price | Higher cost | Lower cost |

| Typical Uses | Cookware, heavy-duty appliances | Cookware, light appliances, household items |

Introduction to Cast Iron Enamel and Steel Enamel

Cast iron enamel features a durable glass coating fused to cast iron, enhancing resistance to stains, scratches, and heat, making it ideal for cookware and architectural applications. Steel enamel involves applying a vitreous enamel layer onto steel substrates, offering corrosion resistance and a smooth, glossy finish suitable for appliances and industrial equipment. Both materials combine metal strength with enamel's protective properties but differ in base metal composition and typical use cases, influencing durability and aesthetic appeal.

Composition and Manufacturing Differences

Cast iron enamel typically involves a thicker iron base with higher carbon content, providing enhanced durability and heat retention, while steel enamel uses a thinner, low-carbon steel substrate that offers greater flexibility and lighter weight. The manufacturing process for cast iron enamel includes acid etching to improve enamel adhesion and longer firing times at temperatures around 760-850degC to create a robust vitreous coating. Steel enamel manufacturing often employs phosphating treatments and faster enameling cycles at similar firing temperatures, resulting in a smoother surface finish and improved resistance to chipping.

Durability: Cast Iron Enamel vs Steel Enamel

Cast iron enamel offers superior durability due to its thicker, more rigid base which resists chipping and cracking over time, making it ideal for heavy-duty applications and high heat. Steel enamel, while lighter and more flexible, is more prone to dents and scratches but can maintain a smoother finish with proper care. The choice between cast iron and steel enamel depends largely on the specific durability demands and usage conditions.

Heat Retention and Distribution Comparison

Cast iron enamel excels in heat retention due to its dense structure, maintaining consistent temperatures for extended periods, which makes it ideal for slow cooking. Steel enamel offers faster heat distribution because of its lighter weight and higher thermal conductivity, allowing for quicker response to temperature changes. Choosing between cast iron and steel enamel depends on cooking style, with cast iron suited for even heat maintenance and steel for rapid heating adjustments.

Weight and Ease of Handling

Cast iron enamel cookware is generally heavier and more cumbersome, making it less convenient for everyday handling compared to steel enamel. Steel enamel offers a lighter weight, enhancing ease of maneuverability and reducing fatigue during cooking tasks. This weight difference significantly impacts user comfort, especially in larger pots and pans used frequently in the kitchen.

Resistance to Chipping and Scratching

Cast iron enamel exhibits superior resistance to chipping and scratching due to its thicker base and more robust enamel layer compared to steel enamel, which typically has a thinner coating susceptible to wear. The thicker enamel on cast iron creates a tougher, more durable surface that withstands heavy use and impact better than steel enamel. Steel enamel, while lighter and more flexible, is more prone to chipping and scratching under repeated mechanical stress.

Maintenance and Cleaning Requirements

Cast iron enamel requires careful maintenance to prevent chipping due to its brittle nature, with gentle cleaning using non-abrasive sponges and mild detergents recommended to preserve the glossy surface. Steel enamel offers greater durability and resistance to cracking, allowing for more rigorous cleaning methods, including the use of harsher detergents and scrubbing tools without compromising the enamel coating. Both materials benefit from prompt removal of acidic or alkaline substances to avoid etching or discoloration of the enamel finish.

Cooking Performance and Applications

Cast iron enamel offers superior heat retention and even cooking, making it ideal for slow-cooking and simmering dishes; steel enamel heats up faster but may have less consistent temperature distribution, suitable for quick sauteing and boiling. Cast iron's durability and weight provide excellent searing and browning, while steel enamel's lightweight design allows for easier handling and faster responsiveness. Cookware made from cast iron enamel is preferred for oven use and long cooking times, whereas steel enamel excels in stove-top applications where rapid temperature changes are needed.

Price and Value Considerations

Cast iron enamel typically commands a higher price due to its durability and superior heat retention, making it a valuable investment for long-term use. Steel enamel offers a more affordable option with lighter weight, appealing to budget-conscious buyers seeking reasonable durability. Evaluating price against lifespan and maintenance costs helps determine the best value choice between cast iron enamel and steel enamel cookware.

Choosing the Right Enamel Material for Your Needs

Cast iron enamel offers exceptional durability and heat retention, making it ideal for cookware and heavy-duty applications, while steel enamel provides lightweight strength and resistance to corrosion, suited for decorative and household items. The choice between cast iron enamel and steel enamel depends on the intended use, with cast iron preferred for high-temperature cooking and steel favored for lighter, more versatile structures. Assessing factors such as thermal performance, weight, and application will guide selecting the right enamel material for your specific requirements.

Cast iron enamel vs Steel enamel Infographic

materialdif.com

materialdif.com