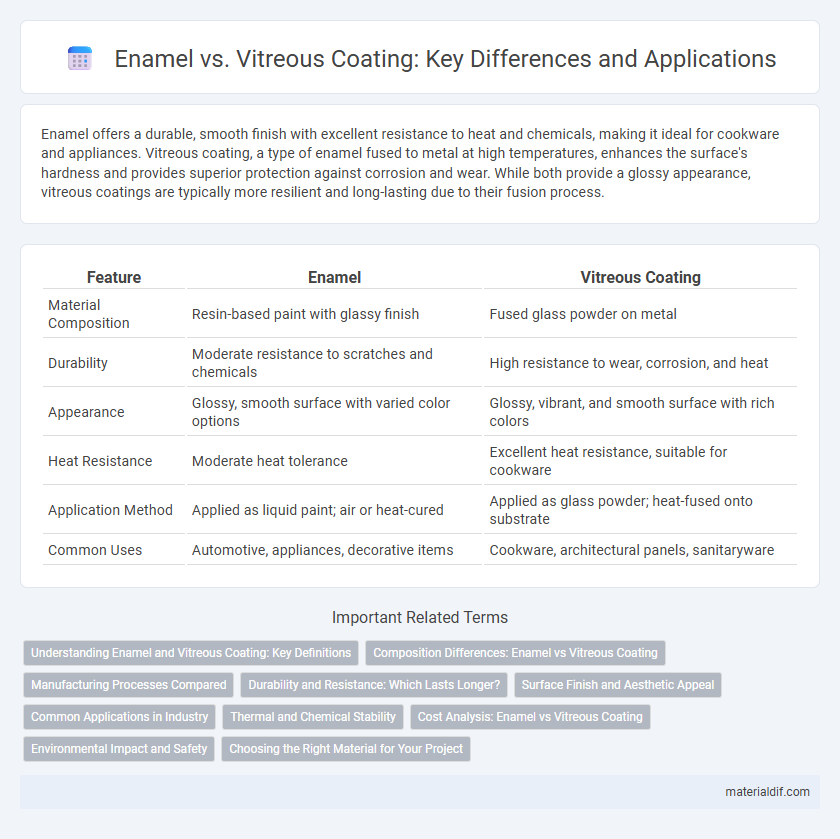

Enamel offers a durable, smooth finish with excellent resistance to heat and chemicals, making it ideal for cookware and appliances. Vitreous coating, a type of enamel fused to metal at high temperatures, enhances the surface's hardness and provides superior protection against corrosion and wear. While both provide a glossy appearance, vitreous coatings are typically more resilient and long-lasting due to their fusion process.

Table of Comparison

| Feature | Enamel | Vitreous Coating |

|---|---|---|

| Material Composition | Resin-based paint with glassy finish | Fused glass powder on metal |

| Durability | Moderate resistance to scratches and chemicals | High resistance to wear, corrosion, and heat |

| Appearance | Glossy, smooth surface with varied color options | Glossy, vibrant, and smooth surface with rich colors |

| Heat Resistance | Moderate heat tolerance | Excellent heat resistance, suitable for cookware |

| Application Method | Applied as liquid paint; air or heat-cured | Applied as glass powder; heat-fused onto substrate |

| Common Uses | Automotive, appliances, decorative items | Cookware, architectural panels, sanitaryware |

Understanding Enamel and Vitreous Coating: Key Definitions

Enamel is a durable, glass-like coating fused onto metal or ceramic surfaces through high-temperature firing, providing a hard, glossy finish that resists corrosion and wear. Vitreous coating, often synonymous with vitreous enamel, refers specifically to the fused glass layer applied to substrates like steel or cast iron, designed to enhance surface durability and chemical resistance. Understanding the distinctions involves recognizing that enamel is the material itself, while vitreous coating emphasizes the glassy, vitreous nature of the enamel layer formed during the firing process.

Composition Differences: Enamel vs Vitreous Coating

Enamel consists of powdered glass fused to a substrate through high-temperature firing, creating a smooth, durable, and glossy surface. Vitreous coating, also known as vitreous enamel, employs finely ground glass particles melted at high temperatures to produce a hard, impermeable layer resistant to corrosion and scratching. The key composition difference lies in enamel's use of glass fused with metal oxides, while vitreous coating emphasizes a pure glass matrix without organic binders, enhancing chemical stability and longevity.

Manufacturing Processes Compared

Enamel and vitreous coatings both involve fusing powdered glass to a substrate through high-temperature firing, but enamel typically uses a thicker glass layer applied via wet or dry processes before kiln firing, while vitreous coating employs a thinner, more uniform layer often deposited through spraying techniques. The enamel manufacturing process requires precise temperature control between 750degC and 900degC to ensure proper adhesion and durability, whereas vitreous coatings may undergo multiple firings to achieve optimal surface smoothness and chemical resistance. Both methods emphasize surface preparation and thermal consistency, yet enamel tends to yield a more robust, chip-resistant finish ideal for heavy-duty applications.

Durability and Resistance: Which Lasts Longer?

Enamel offers exceptional durability with its thick, hard surface that resists chipping and cracking under heavy use, making it ideal for cookware and industrial applications. Vitreous coating, composed of fused glass powders, provides superior resistance to rust, corrosion, and high temperatures but may be more prone to impact damage over time. When comparing longevity, enamel's robustness outperforms vitreous coating in scenarios requiring sustained mechanical strength, while vitreous coating excels in chemical and heat resistance.

Surface Finish and Aesthetic Appeal

Enamel offers a smooth, glossy surface finish that enhances its vibrant color retention and provides a durable, chip-resistant coating ideal for decorative and functional applications. Vitreous coating, composed of fused glass particles, creates a harder, more scratch-resistant surface with a slightly textured appearance that can add depth and subtle variations to the aesthetic appeal. Both finishes enhance durability and visual appeal, but enamel is favored for its high gloss and rich color, while vitreous coating excels in surface hardness and resistance to wear.

Common Applications in Industry

Enamel and vitreous coatings are extensively used in industrial applications for their durability and corrosion resistance. Enamel coatings are commonly applied to household appliances, cookware, and architectural panels due to their smooth, glossy finish and heat resistance. Vitreous coatings find widespread use in sanitary ware, automotive components, and construction materials, offering superior chemical resistance and long-lasting protection.

Thermal and Chemical Stability

Enamel offers superior thermal stability withstanding high temperatures without degradation, while vitreous coating may crack or discolor under extreme heat. Chemically, enamel provides excellent resistance to acids, alkalis, and oxidation, enhancing durability in harsh environments. Vitreous coatings, although protective, generally exhibit lower chemical resistance compared to enamel, making enamel the preferred choice for demanding thermal and chemical applications.

Cost Analysis: Enamel vs Vitreous Coating

Enamel coatings generally present a lower upfront cost compared to vitreous coatings, making them a budget-friendly option for various applications. Vitreous coatings, though more expensive initially, offer superior durability and resistance to chemicals and heat, which can reduce long-term maintenance and replacement expenses. Cost analysis favors enamel for short-term projects, while vitreous coatings prove more economical over extended use due to enhanced lifespan and performance.

Environmental Impact and Safety

Enamel coatings, primarily composed of powdered glass fused onto metal, offer durability with low environmental impact due to their inert, non-toxic composition and lack of harmful emissions during production. Vitreous coatings, similarly glass-based, differ slightly in formulation but share comparable safety profiles, being non-reactive and safe for food contact. Both coatings withstand high temperatures without releasing volatile organic compounds (VOCs), making them environmentally friendly and safe for household and industrial use.

Choosing the Right Material for Your Project

Enamel offers a durable, glossy finish that is highly resistant to heat and chemical exposure, making it ideal for kitchenware and industrial applications. Vitreous coating, a type of enamel fused to metal at high temperatures, provides superior hardness and chip resistance, often used in appliances and architectural surfaces. Selecting the right material depends on factors such as durability requirements, environmental exposure, and aesthetic preferences to ensure long-lasting performance and appearance.

Enamel vs Vitreous Coating Infographic

materialdif.com

materialdif.com