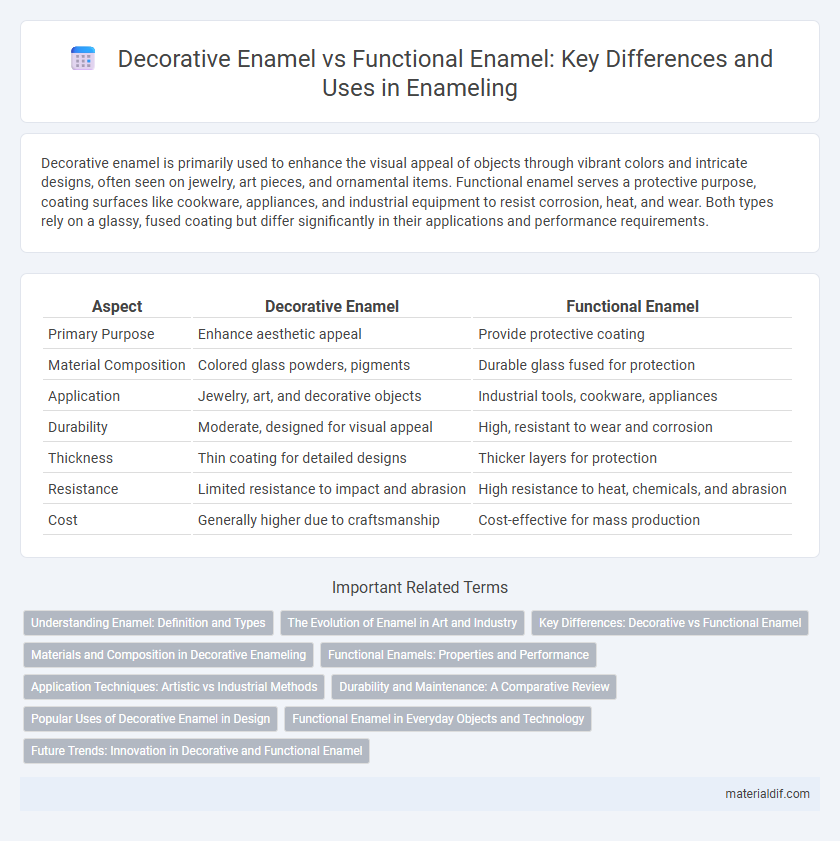

Decorative enamel is primarily used to enhance the visual appeal of objects through vibrant colors and intricate designs, often seen on jewelry, art pieces, and ornamental items. Functional enamel serves a protective purpose, coating surfaces like cookware, appliances, and industrial equipment to resist corrosion, heat, and wear. Both types rely on a glassy, fused coating but differ significantly in their applications and performance requirements.

Table of Comparison

| Aspect | Decorative Enamel | Functional Enamel |

|---|---|---|

| Primary Purpose | Enhance aesthetic appeal | Provide protective coating |

| Material Composition | Colored glass powders, pigments | Durable glass fused for protection |

| Application | Jewelry, art, and decorative objects | Industrial tools, cookware, appliances |

| Durability | Moderate, designed for visual appeal | High, resistant to wear and corrosion |

| Thickness | Thin coating for detailed designs | Thicker layers for protection |

| Resistance | Limited resistance to impact and abrasion | High resistance to heat, chemicals, and abrasion |

| Cost | Generally higher due to craftsmanship | Cost-effective for mass production |

Understanding Enamel: Definition and Types

Enamel is a smooth, durable coating applied to metal or ceramic surfaces, valued for both aesthetic appeal and protective qualities. Decorative enamel emphasizes intricate designs and vibrant colors to enhance visual appeal, commonly found in jewelry and art pieces. Functional enamel serves as a protective layer, providing resistance to corrosion, heat, and wear in industrial applications and cookware.

The Evolution of Enamel in Art and Industry

Decorative enamel has evolved as a vibrant artistic medium, showcasing intricate designs and vivid colors on jewelry, sculptures, and ornamental objects. Functional enamel, used in industrial applications, provides durable, protective coatings on appliances, cookware, and architectural materials, ensuring resistance to corrosion and heat. The evolution of enamel reflects a convergence of aesthetic refinement and technological advancement, bridging art and industry through improved techniques and material science.

Key Differences: Decorative vs Functional Enamel

Decorative enamel primarily enhances the visual appeal of objects with vibrant colors and intricate designs, often used in jewelry, art, and ornamental pieces. Functional enamel provides a protective, durable coating that resists corrosion, heat, and wear, commonly applied in cookware, industrial equipment, and electronics. The key differences lie in decorative enamel's aesthetic focus versus functional enamel's emphasis on durability and protection.

Materials and Composition in Decorative Enameling

Decorative enamel primarily utilizes vibrant glass powders composed of silica, fluxes, and colorants such as metal oxides like cobalt or copper to achieve rich hues and intricate designs. These materials are finely ground and fused onto metal surfaces like copper or silver through controlled firing processes that enhance aesthetic appeal without emphasizing durability. The composition often includes softer fluxes and additives that optimize color brightness and smoothness, distinguishing decorative enameling from functional enamel's focus on heat resistance and protection.

Functional Enamels: Properties and Performance

Functional enamels exhibit exceptional durability, chemical resistance, and thermal stability, making them suitable for protective coatings on appliances, cookware, and industrial equipment. Their composition is engineered to withstand mechanical wear, corrosion, and high temperatures without compromising adhesion or gloss. Key performance metrics include high hardness, resistance to scratching, and long-term color retention, ensuring both longevity and effectiveness in demanding environments.

Application Techniques: Artistic vs Industrial Methods

Decorative enamel applications employ artistic techniques such as hand-painting, cloisonne, and champleve to create intricate, visually striking designs on jewelry, ceramics, and art objects. Functional enamel utilizes industrial methods including powder coating, kiln-firing, and electrostatic deposition to produce durable, protective coatings on appliances, cookware, and architectural elements. The contrast between these application techniques highlights the emphasis on aesthetic detail in decorative enamel versus the efficiency and resilience demanded by functional enamel.

Durability and Maintenance: A Comparative Review

Decorative enamel offers vibrant colors and intricate designs but generally lacks the durability of functional enamel, which is engineered to withstand wear, corrosion, and high temperatures. Functional enamel requires less frequent maintenance due to its resistance to chipping, scratching, and chemical damage, making it ideal for industrial applications. Decorative enamel, while visually appealing, demands careful upkeep to prevent fading and surface degradation over time.

Popular Uses of Decorative Enamel in Design

Decorative enamel is widely used in design for jewelry, watchmaking, and ornamental art due to its vibrant colors and ability to create intricate patterns on metal surfaces. Unlike functional enamel, which provides protective coating in industrial applications, decorative enamel enhances aesthetic appeal with techniques like cloisonne, champleve, and plique-a-jour. Popular designs often incorporate decorative enamel to produce detailed, colorful motifs that elevate the visual impact of luxury items and bespoke craftsmanship.

Functional Enamel in Everyday Objects and Technology

Functional enamel enhances everyday objects and technology by providing durable, protective coatings that resist corrosion, heat, and wear. Commonly used in cookware, appliances, and electronic components, functional enamel ensures longevity and maintains performance under harsh conditions. This specialized coating improves usability by combining aesthetic appeal with practical benefits such as electrical insulation and chemical resistance.

Future Trends: Innovation in Decorative and Functional Enamel

Future trends in enamel highlight significant innovation in both decorative and functional applications, driven by advances in nanotechnology and material science. Decorative enamel is evolving with enhanced color durability, complexity of design, and integration with digital printing techniques, expanding artistic possibilities. Functional enamel improvements focus on increased resistance to wear, corrosion, and thermal stress, enabling broader industrial and architectural uses.

Decorative enamel vs Functional enamel Infographic

materialdif.com

materialdif.com