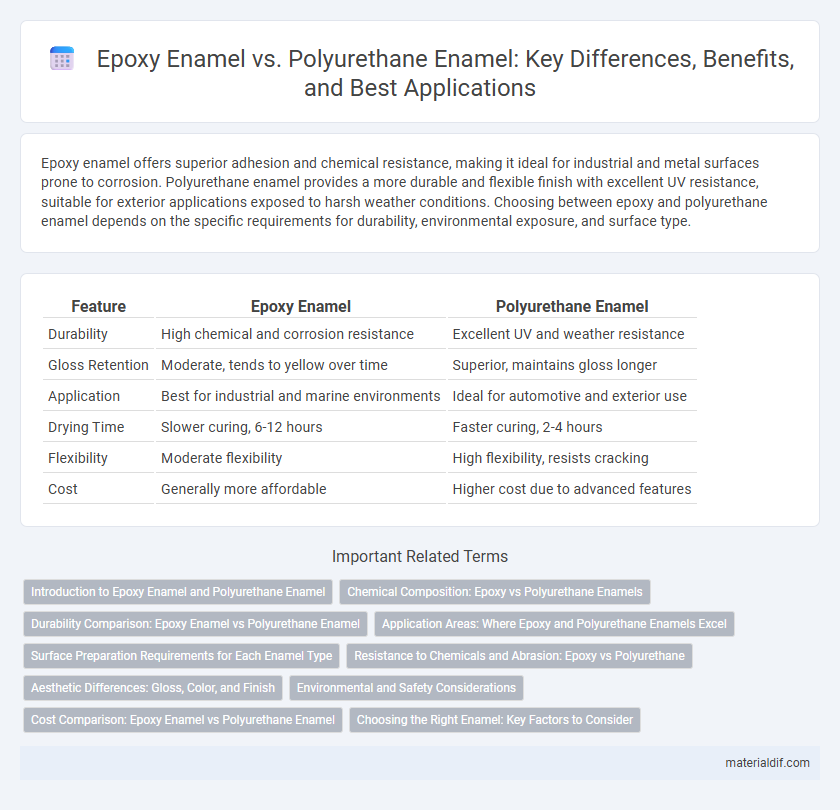

Epoxy enamel offers superior adhesion and chemical resistance, making it ideal for industrial and metal surfaces prone to corrosion. Polyurethane enamel provides a more durable and flexible finish with excellent UV resistance, suitable for exterior applications exposed to harsh weather conditions. Choosing between epoxy and polyurethane enamel depends on the specific requirements for durability, environmental exposure, and surface type.

Table of Comparison

| Feature | Epoxy Enamel | Polyurethane Enamel |

|---|---|---|

| Durability | High chemical and corrosion resistance | Excellent UV and weather resistance |

| Gloss Retention | Moderate, tends to yellow over time | Superior, maintains gloss longer |

| Application | Best for industrial and marine environments | Ideal for automotive and exterior use |

| Drying Time | Slower curing, 6-12 hours | Faster curing, 2-4 hours |

| Flexibility | Moderate flexibility | High flexibility, resists cracking |

| Cost | Generally more affordable | Higher cost due to advanced features |

Introduction to Epoxy Enamel and Polyurethane Enamel

Epoxy enamel is a durable coating known for its strong adhesion and excellent chemical resistance, often used in industrial and marine environments to protect metal surfaces. Polyurethane enamel offers superior UV resistance and flexibility, making it ideal for automotive and outdoor applications where weather durability is crucial. Both coatings provide robust protection, but epoxy enamel excels in corrosion resistance while polyurethane enamel delivers enhanced aesthetic longevity.

Chemical Composition: Epoxy vs Polyurethane Enamels

Epoxy enamel consists primarily of epoxy resins, which are formed from the reaction of epichlorohydrin and bisphenol-A, creating a cross-linked polymer network known for excellent adhesion and chemical resistance. Polyurethane enamel is derived from the reaction between polyols and isocyanates, producing a flexible, durable coating with superior UV resistance and gloss retention. The key chemical difference lies in epoxy's amine or anhydride curing agents versus polyurethane's isocyanate-based curing, influencing their mechanical properties and application suitability.

Durability Comparison: Epoxy Enamel vs Polyurethane Enamel

Epoxy enamel offers superior chemical resistance and adhesion, making it highly durable against corrosion and wear in industrial environments. Polyurethane enamel excels in UV resistance and flexibility, preventing cracks and maintaining gloss over prolonged outdoor exposure. Choosing between epoxy and polyurethane enamel depends on the specific durability requirements related to chemical exposure, weather conditions, and surface flexibility.

Application Areas: Where Epoxy and Polyurethane Enamels Excel

Epoxy enamel is highly effective in industrial and marine applications due to its superior chemical resistance and strong adhesion to metal surfaces. Polyurethane enamel excels in automotive and architectural coatings, offering excellent UV resistance and a durable, glossy finish suitable for exterior environments. Both enamels provide robust protective qualities but are chosen based on specific environmental exposure and performance requirements.

Surface Preparation Requirements for Each Enamel Type

Epoxy enamel requires thorough surface preparation, including sandblasting or abrasive cleaning to ensure optimal adhesion and corrosion resistance. Polyurethane enamel demands a clean, dry surface often treated with a suitable primer to enhance flexibility and UV durability. Both enamels benefit from removing grease, rust, and contaminants, but epoxy enamel is more sensitive to moisture during application.

Resistance to Chemicals and Abrasion: Epoxy vs Polyurethane

Epoxy enamel offers exceptional resistance to chemicals such as acids, alkalis, and solvents, making it ideal for industrial environments requiring durable protective coatings. Polyurethane enamel excels in abrasion resistance and maintains its gloss and flexibility under mechanical stress, providing long-lasting aesthetic appeal. Choosing between epoxy and polyurethane enamels depends on prioritizing either superior chemical resistance or enhanced abrasion durability for specific application needs.

Aesthetic Differences: Gloss, Color, and Finish

Epoxy enamel offers a high-gloss finish with excellent color retention, creating a smooth and durable surface ideal for industrial applications. Polyurethane enamel provides a more versatile range of gloss levels, from matte to high gloss, with superior UV resistance that maintains color vibrancy over time. The choice between epoxy and polyurethane enamel depends on the desired aesthetic outcome, with epoxy favored for its glossy hardness and polyurethane for its rich color depth and finish variety.

Environmental and Safety Considerations

Epoxy enamel contains bisphenol A (BPA) and volatile organic compounds (VOCs), which pose environmental hazards and require careful handling due to toxicity and potential respiratory irritation. Polyurethane enamel offers better environmental performance with lower VOC emissions and improved chemical resistance, reducing health risks during application and curing. Selecting polyurethane enamel supports eco-friendly practices and enhances workplace safety by minimizing exposure to harmful substances.

Cost Comparison: Epoxy Enamel vs Polyurethane Enamel

Epoxy enamel typically has a lower initial cost compared to polyurethane enamel, making it a more budget-friendly option for many industrial applications. Polyurethane enamel, while more expensive upfront, offers superior UV resistance and durability, potentially reducing long-term maintenance and replacement costs. When evaluating total cost of ownership, epoxy enamel may be more economical for indoor or low-exposure environments, whereas polyurethane enamel is often more cost-effective for outdoor or high-exposure settings due to its extended lifespan.

Choosing the Right Enamel: Key Factors to Consider

Epoxy enamel offers superior chemical resistance and durability, making it ideal for industrial applications where corrosion protection is critical. Polyurethane enamel provides excellent UV resistance and flexibility, suited for outdoor surfaces exposed to weathering and abrasion. Consider factors such as environmental exposure, surface type, and required longevity when selecting between epoxy and polyurethane enamel coatings.

Epoxy enamel vs polyurethane enamel Infographic

materialdif.com

materialdif.com