Wet enamel offers a glossy, smooth finish that enhances color vibrancy and provides better adhesion for subsequent layers, making it ideal for detailed artistry and protective coatings. Dry enamel, on the other hand, results in a hard, durable surface resistant to chipping and scratches, commonly used for long-lasting finishes on metal and wood. Understanding the differences between wet and dry enamel ensures optimal application and durability based on the specific project requirements.

Table of Comparison

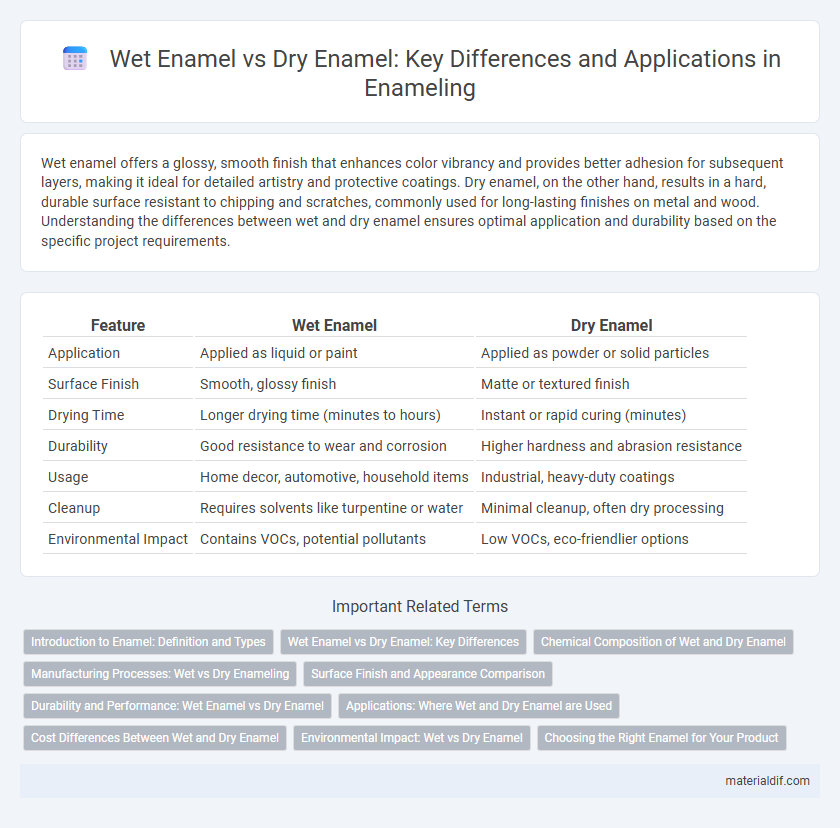

| Feature | Wet Enamel | Dry Enamel |

|---|---|---|

| Application | Applied as liquid or paint | Applied as powder or solid particles |

| Surface Finish | Smooth, glossy finish | Matte or textured finish |

| Drying Time | Longer drying time (minutes to hours) | Instant or rapid curing (minutes) |

| Durability | Good resistance to wear and corrosion | Higher hardness and abrasion resistance |

| Usage | Home decor, automotive, household items | Industrial, heavy-duty coatings |

| Cleanup | Requires solvents like turpentine or water | Minimal cleanup, often dry processing |

| Environmental Impact | Contains VOCs, potential pollutants | Low VOCs, eco-friendlier options |

Introduction to Enamel: Definition and Types

Enamel is a glassy, colored coating fused to metal surfaces, commonly used in jewelry and decorative arts, available in two main forms: wet enamel and dry enamel. Wet enamel consists of powdered glass mixed with a liquid binder that requires firing at high temperatures to fuse onto the substrate, providing vibrant, durable finishes. Dry enamel, also known as cold enamel, is a resin-based coating applied without heat, offering a quicker application with less durability compared to wet enamel.

Wet Enamel vs Dry Enamel: Key Differences

Wet enamel contains solvents that keep it liquid for easier application, offering smooth, glossy finishes and quicker touch-ups. Dry enamel, free of solvents, provides greater durability and a tougher, more scratch-resistant surface after curing. These key differences influence the choice between flexibility during painting and long-term surface protection.

Chemical Composition of Wet and Dry Enamel

Wet enamel contains solvents such as water or organic compounds that keep the binder and pigments in a liquid state, facilitating application and adhesion; its chemical composition includes resin binders, pigments, additives, and solvents. Dry enamel results from the evaporation of solvents during curing, leaving behind a solid film primarily composed of resin and pigments that form a durable, protective layer. Differences in chemical composition between wet and dry enamel influence properties such as viscosity, drying time, and final hardness of the coating.

Manufacturing Processes: Wet vs Dry Enameling

Wet enameling involves applying a liquid glass suspension onto metal surfaces, followed by firing at high temperatures to create a smooth, durable coating. Dry enameling, also known as dry powder enameling, uses powdered glass fused onto substrates through controlled heat without the use of solvents or binders. Manufacturing processes for wet enamel require precise control of viscosity and drying times, whereas dry enamel techniques offer faster curing cycles and reduced environmental impact due to the absence of liquid waste.

Surface Finish and Appearance Comparison

Wet enamel produces a glossy, smooth surface finish that enhances color vibrancy and depth, making it ideal for detailed artwork and jewelry applications. Dry enamel, also known as vitreous enamel, results in a durable, glass-like coating with a matte or satin finish, providing excellent resistance to scratches and wear. The choice between wet and dry enamel significantly affects the appearance and durability, with wet enamel favored for vibrant, lustrous aesthetics and dry enamel preferred for robust, long-lasting surfaces.

Durability and Performance: Wet Enamel vs Dry Enamel

Wet enamel offers superior adhesion and flexibility during application, resulting in enhanced durability and resistance to chipping compared to dry enamel. Dry enamel, while easier to handle, often lacks the resilience of wet enamel, leading to quicker wear and potential cracking under stress. The choice between wet and dry enamel significantly impacts the longevity and performance of coated surfaces, with wet enamel preferred for high-traffic or exposed environments.

Applications: Where Wet and Dry Enamel are Used

Wet enamel is primarily used in automotive refinishing and industrial coatings due to its smooth application and durability on metal surfaces, while dry enamel is favored in fine arts for detailed artwork and jewelry making because of its ease of layering and color precision. In construction, wet enamel finds applications in protective coatings for machinery and outdoor equipment, whereas dry enamel is commonly applied in decorative tiles and glasswork. Both types serve specific functions where wet enamel offers strong adhesion and weather resistance, and dry enamel provides intricate design flexibility and vibrant color retention.

Cost Differences Between Wet and Dry Enamel

Wet enamel typically incurs higher costs due to the need for solvents, longer drying times, and additional ventilation equipment, increasing overall production expenses. Dry enamel, often involving powder coatings, reduces material waste and energy consumption, resulting in lower operational costs and faster application processes. Companies opting for dry enamel benefit from decreased environmental compliance expenses and improved efficiency, making it a cost-effective alternative to wet enamel.

Environmental Impact: Wet vs Dry Enamel

Wet enamel coatings release volatile organic compounds (VOCs) during application and drying, contributing significantly to air pollution and requiring complex solvent recovery systems. Dry enamel, often in powder form, eliminates VOC emissions entirely, offering a more environmentally sustainable option with minimal hazardous waste generation. Choosing dry enamel reduces the carbon footprint and complies better with stringent environmental regulations, promoting cleaner production processes.

Choosing the Right Enamel for Your Product

Selecting the appropriate enamel depends on the product's intended use and environmental exposure; wet enamel offers superior adhesion and vibrant color retention during application, while dry enamel provides enhanced durability and resistance to wear after curing. Manufacturers prioritize wet enamel for intricate detailing and quick, smooth finishes, whereas dry enamel is favored for coatings that demand long-term corrosion and abrasion resistance. Understanding the specific performance requirements and application conditions ensures optimal durability and aesthetic quality in enamel-coated products.

wet enamel vs dry enamel Infographic

materialdif.com

materialdif.com