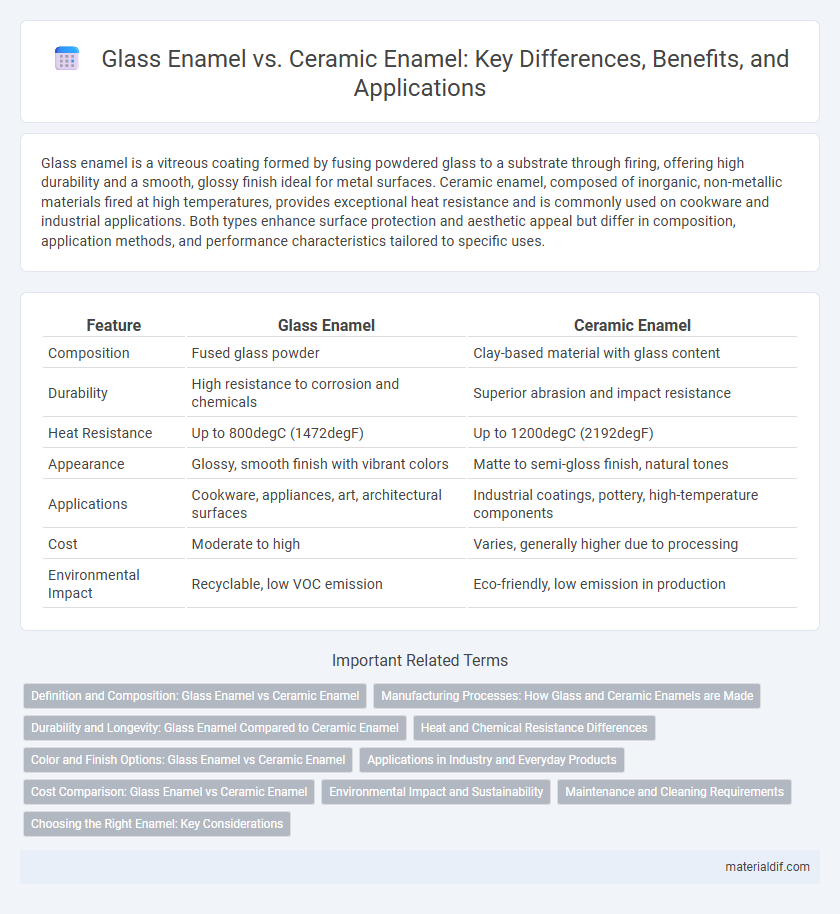

Glass enamel is a vitreous coating formed by fusing powdered glass to a substrate through firing, offering high durability and a smooth, glossy finish ideal for metal surfaces. Ceramic enamel, composed of inorganic, non-metallic materials fired at high temperatures, provides exceptional heat resistance and is commonly used on cookware and industrial applications. Both types enhance surface protection and aesthetic appeal but differ in composition, application methods, and performance characteristics tailored to specific uses.

Table of Comparison

| Feature | Glass Enamel | Ceramic Enamel |

|---|---|---|

| Composition | Fused glass powder | Clay-based material with glass content |

| Durability | High resistance to corrosion and chemicals | Superior abrasion and impact resistance |

| Heat Resistance | Up to 800degC (1472degF) | Up to 1200degC (2192degF) |

| Appearance | Glossy, smooth finish with vibrant colors | Matte to semi-gloss finish, natural tones |

| Applications | Cookware, appliances, art, architectural surfaces | Industrial coatings, pottery, high-temperature components |

| Cost | Moderate to high | Varies, generally higher due to processing |

| Environmental Impact | Recyclable, low VOC emission | Eco-friendly, low emission in production |

Definition and Composition: Glass Enamel vs Ceramic Enamel

Glass enamel is a vitreous coating made by fusing powdered glass to a substrate at high temperatures, consisting mainly of silica, fluxes, and metal oxides that form a smooth, glossy surface. Ceramic enamel, often referred to as porcelain enamel, incorporates similar glass components but includes ceramic oxides that enhance hardness, durability, and resistance to heat and chemicals. Both enamels provide protective and decorative finishes, with glass enamel focusing on aesthetic gloss and flexibility, while ceramic enamel emphasizes robustness and long-term wear resistance.

Manufacturing Processes: How Glass and Ceramic Enamels are Made

Glass enamel is produced by fusing powdered glass to a substrate through high-temperature firing processes, typically between 750degC and 850degC, which creates a smooth, durable coating. Ceramic enamel involves mixing inorganic materials such as clay, silica, and metal oxides, then applying the mixture and firing it at temperatures often exceeding 1000degC to form a hard, heat-resistant surface. Both manufacturing techniques rely on precise temperature control and material composition to optimize adhesion, color, and durability.

Durability and Longevity: Glass Enamel Compared to Ceramic Enamel

Glass enamel demonstrates superior durability and longevity compared to ceramic enamel due to its strong resistance to chipping, cracking, and corrosion. The fusion of glass particles at high temperatures creates a hard, non-porous surface that maintains color vibrancy and structural integrity over extended periods. Ceramic enamel, while heat-resistant, tends to be more susceptible to wear and surface damage under heavy use, leading to shorter lifespan in comparison.

Heat and Chemical Resistance Differences

Glass enamel exhibits superior chemical resistance due to its non-porous, vitrified surface, effectively resisting acids, alkalis, and detergents, while ceramic enamel often offers higher heat resistance, tolerating temperatures beyond 1200degC because of its crystalline structure. The thermal expansion coefficient of glass enamel is typically lower, which can affect its durability under rapid temperature changes compared to ceramic enamel. These distinct heat and chemical resistance properties influence their applications in cookware, industrial coatings, and architectural surfaces.

Color and Finish Options: Glass Enamel vs Ceramic Enamel

Glass enamel offers a vibrant, glossy finish with a wide spectrum of intense colors, making it ideal for decorative surfaces requiring high visual impact. Ceramic enamel provides a more muted, matte appearance with subtle color variations, often preferred for durable, functional applications due to its heat resistance and toughness. Both types enable customization, yet glass enamel excels in brightness and translucency while ceramic enamel emphasizes long-lasting, earthy tones.

Applications in Industry and Everyday Products

Glass enamel provides a durable, corrosion-resistant coating widely used in cookware, appliances, and architectural panels due to its ability to fuse seamlessly to metals. Ceramic enamel, characterized by its heat resistance and insulating properties, finds applications in electronic components, high-temperature industrial equipment, and specialized laboratory ware. Both enamels enhance product longevity and aesthetic appeal but are selected based on specific application requirements such as thermal stability and surface hardness.

Cost Comparison: Glass Enamel vs Ceramic Enamel

Glass enamel generally costs less than ceramic enamel due to its simpler manufacturing process and lower raw material expenses. Ceramic enamel involves higher production costs stemming from its complex firing techniques and superior durability features. Choosing between glass and ceramic enamel depends on budget constraints and the desired longevity of the final product.

Environmental Impact and Sustainability

Glass enamel typically has a lower environmental impact due to its ability to be recycled and its use of natural raw materials like silica, soda ash, and limestone, which are abundant and less energy-intensive to process. Ceramic enamel, while offering enhanced durability and heat resistance, often requires higher firing temperatures and more complex manufacturing processes, resulting in increased energy consumption and carbon emissions. Sustainable production of both types increasingly emphasizes reducing hazardous emissions and incorporating recycled content to minimize ecological footprints.

Maintenance and Cleaning Requirements

Glass enamel surfaces are highly resistant to stains and scratches, requiring only mild detergents and soft cloths for routine cleaning, which helps maintain their glossy finish without much effort. Ceramic enamel, while also durable, typically demands more careful maintenance to prevent chipping and staining, often needing non-abrasive cleaners and gentle handling. Both materials benefit from prompt cleaning of spills to preserve their aesthetic and functional properties over time.

Choosing the Right Enamel: Key Considerations

Glass enamel offers superior gloss and chemical resistance, making it ideal for decorative surfaces and cookware, while ceramic enamel provides enhanced durability and heat tolerance suitable for industrial applications and high-temperature environments. Selecting the right enamel depends on factors such as application type, exposure to heat or chemicals, and longevity requirements. Evaluating these key considerations ensures optimal performance and aesthetics in both glass and ceramic enamel coatings.

Glass enamel vs Ceramic enamel Infographic

materialdif.com

materialdif.com