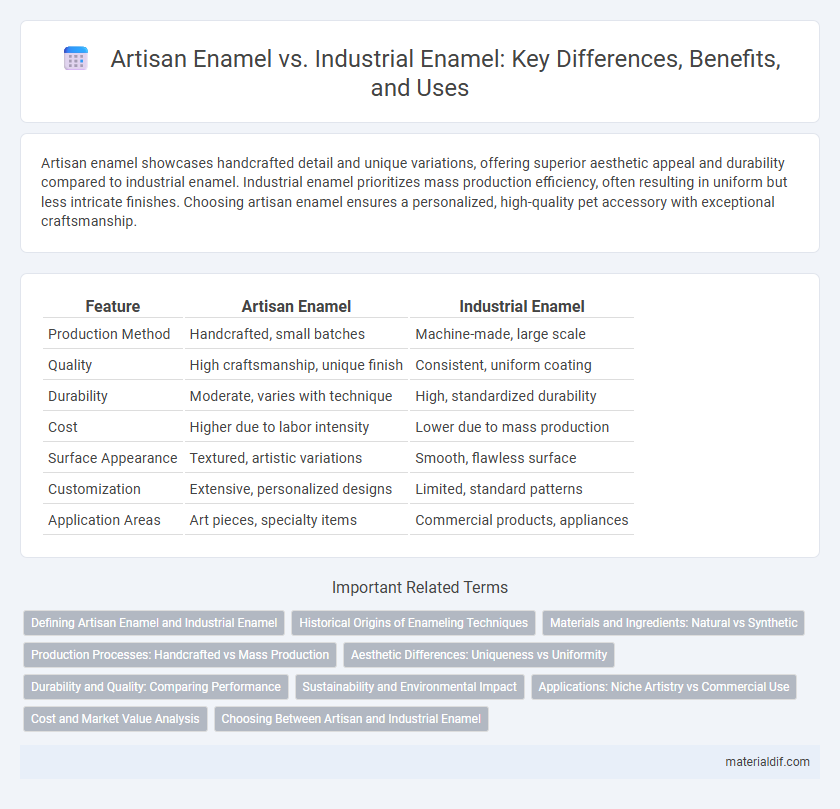

Artisan enamel showcases handcrafted detail and unique variations, offering superior aesthetic appeal and durability compared to industrial enamel. Industrial enamel prioritizes mass production efficiency, often resulting in uniform but less intricate finishes. Choosing artisan enamel ensures a personalized, high-quality pet accessory with exceptional craftsmanship.

Table of Comparison

| Feature | Artisan Enamel | Industrial Enamel |

|---|---|---|

| Production Method | Handcrafted, small batches | Machine-made, large scale |

| Quality | High craftsmanship, unique finish | Consistent, uniform coating |

| Durability | Moderate, varies with technique | High, standardized durability |

| Cost | Higher due to labor intensity | Lower due to mass production |

| Surface Appearance | Textured, artistic variations | Smooth, flawless surface |

| Customization | Extensive, personalized designs | Limited, standard patterns |

| Application Areas | Art pieces, specialty items | Commercial products, appliances |

Defining Artisan Enamel and Industrial Enamel

Artisan enamel is defined by its handcrafted techniques, emphasizing individual craftsmanship and unique, intricate designs often created through manual application and firing processes. Industrial enamel involves mass production methods using automated systems and standardized formulations, prioritizing consistency, durability, and efficiency in coating metal surfaces. These distinctions influence the texture, finish quality, and customization potential of enamel products.

Historical Origins of Enameling Techniques

Artisan enamel techniques trace back to ancient civilizations such as the Egyptians and Byzantines, where handcrafted methods emphasized intricate, labor-intensive designs. Industrial enamel, emerging during the 19th century Industrial Revolution, introduced mechanized processes that allowed mass production and uniform coating on metal surfaces. These historical developments illustrate the transition from traditional artisanal craftsmanship to advanced industrial enamel technology, blending heritage with innovation.

Materials and Ingredients: Natural vs Synthetic

Artisan enamel is crafted using natural minerals and traditional fluxes, resulting in unique textures and rich color variations. Industrial enamel typically incorporates synthetic materials and chemical additives to ensure uniformity, durability, and mass production efficiency. The use of natural ingredients in artisan enamel often leads to more organic finishes, whereas synthetic components in industrial enamel enhance resistance and consistency.

Production Processes: Handcrafted vs Mass Production

Artisan enamel involves meticulous handcrafted techniques that emphasize precision and unique detailing, often requiring skilled artisans to apply multiple layers and firing processes by hand. Industrial enamel relies on automated mass production methods using machinery that ensures consistency, faster turnaround times, and uniform coating across large volumes. The handcrafted process allows for customization and intricate designs, while industrial enamel prioritizes efficiency and scalability in production.

Aesthetic Differences: Uniqueness vs Uniformity

Artisan enamel showcases unique variations and intricate details due to handcrafting techniques, resulting in one-of-a-kind pieces with rich textures and color depth. Industrial enamel, produced through automated processes, emphasizes uniformity and consistency, delivering smooth, flawless finishes ideal for mass production. These aesthetic differences highlight artisan enamel's artistic individuality versus the standardized perfection of industrial enamel.

Durability and Quality: Comparing Performance

Artisan enamel displays superior durability due to meticulous handcrafting processes that allow for precise layering and firing, resulting in enhanced resistance to chipping and fading. Industrial enamel, while produced efficiently in large batches, often sacrifices some quality, leading to a more uniform finish but reduced longevity under heavy wear. Experts note that artisan enamel maintains vibrant colors and structural integrity longer than industrial enamel, making it preferred for high-end applications.

Sustainability and Environmental Impact

Artisan enamel typically involves small-batch, handcrafted processes that prioritize sustainable sourcing and generate less industrial waste compared to large-scale industrial enamel production. Industrial enamel manufacturing often relies on energy-intensive methods and chemical treatments, contributing to higher carbon emissions and environmental pollution. Emphasizing artisan enamel supports eco-friendly practices by reducing the carbon footprint and minimizing hazardous waste in enamel production.

Applications: Niche Artistry vs Commercial Use

Artisan enamel excels in niche artistry, providing unique, handcrafted pieces with intricate designs that showcase individual creativity and cultural heritage. Industrial enamel is optimized for commercial use, featuring standardized coatings that offer high durability and consistent quality for mass production on appliances, automotive parts, and architectural elements. The tailored applications of artisan enamel emphasize aesthetic value, while industrial enamel prioritizes functional resilience and scalability.

Cost and Market Value Analysis

Artisan enamel typically involves handcrafted techniques that result in unique, high-quality pieces with higher production costs, leading to greater market value and exclusivity. Industrial enamel is produced through automated, large-scale processes, significantly reducing manufacturing expenses and allowing for competitive pricing in mass markets. The cost difference translates to artisan enamel commanding premium prices due to craftsmanship, while industrial enamel appeals to budget-conscious consumers seeking durability and standardization.

Choosing Between Artisan and Industrial Enamel

Artisan enamel offers unmatched uniqueness and craftsmanship, characterized by intricate designs and personalized finishes, making it ideal for bespoke jewelry and decorative pieces. Industrial enamel is produced through standardized processes ensuring uniform quality, durability, and cost-effectiveness suitable for mass production in commercial applications. Selecting between artisan and industrial enamel depends on factors like customization needs, budget constraints, and production scale, where artisan enamel prioritizes aesthetic value and industrial enamel emphasizes consistency and efficiency.

Artisan enamel vs Industrial enamel Infographic

materialdif.com

materialdif.com