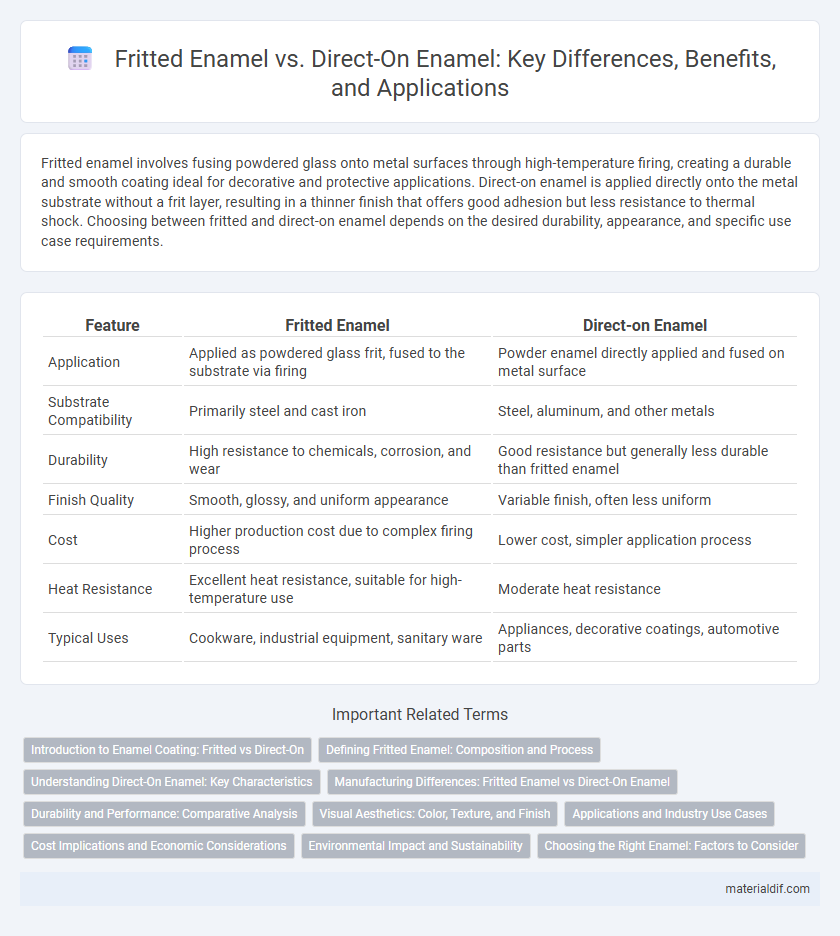

Fritted enamel involves fusing powdered glass onto metal surfaces through high-temperature firing, creating a durable and smooth coating ideal for decorative and protective applications. Direct-on enamel is applied directly onto the metal substrate without a frit layer, resulting in a thinner finish that offers good adhesion but less resistance to thermal shock. Choosing between fritted and direct-on enamel depends on the desired durability, appearance, and specific use case requirements.

Table of Comparison

| Feature | Fritted Enamel | Direct-on Enamel |

|---|---|---|

| Application | Applied as powdered glass frit, fused to the substrate via firing | Powder enamel directly applied and fused on metal surface |

| Substrate Compatibility | Primarily steel and cast iron | Steel, aluminum, and other metals |

| Durability | High resistance to chemicals, corrosion, and wear | Good resistance but generally less durable than fritted enamel |

| Finish Quality | Smooth, glossy, and uniform appearance | Variable finish, often less uniform |

| Cost | Higher production cost due to complex firing process | Lower cost, simpler application process |

| Heat Resistance | Excellent heat resistance, suitable for high-temperature use | Moderate heat resistance |

| Typical Uses | Cookware, industrial equipment, sanitary ware | Appliances, decorative coatings, automotive parts |

Introduction to Enamel Coating: Fritted vs Direct-On

Fritted enamel involves fusing powdered glass onto metal surfaces through high-temperature firing, creating a durable, glossy coating resistant to corrosion and wear. Direct-on enamel applies powdered glass directly to the metal substrate without an intermediate frit layer, allowing for quicker processing but often resulting in less uniform coverage. Both methods offer protective and decorative finishes, with fritted enamel preferred in heavy-duty applications and direct-on enamel favored for cost-effective, lighter-duty uses.

Defining Fritted Enamel: Composition and Process

Fritted enamel is composed of finely ground glass particles that are fused onto a metal substrate through controlled heating, creating a durable, uniform coating. This process involves melting the frit material onto the metal surface, ensuring strong adhesion and resistance to corrosion and wear. Unlike direct-on enamel, which is applied as a wet coat and then fired, fritted enamel provides enhanced durability and a smoother finish due to its pre-melted glass composition.

Understanding Direct-On Enamel: Key Characteristics

Direct-on enamel is applied directly to metal surfaces, offering superior adhesion and durability without requiring an intermediate coating. This enamel type provides a smooth, uniform finish resistant to high temperatures, chemicals, and corrosion, making it ideal for cookware and industrial applications. Its key characteristics include enhanced mechanical bonding and excellent resistance to thermal shock compared to fritted enamel, which involves pre-fused glass particles.

Manufacturing Differences: Fritted Enamel vs Direct-On Enamel

Fritted enamel is manufactured by first fusing a powdered glass frit onto the metal surface at high temperatures, creating a durable base layer before applying the enamel coating. Direct-on enamel involves applying enamel powders directly onto the raw metal substrate without a frit base, requiring precise temperature control to ensure proper adhesion and finish. The manufacturing process for fritted enamel generally offers better corrosion resistance and surface smoothness compared to the more cost-effective but less resilient direct-on enamel method.

Durability and Performance: Comparative Analysis

Fritted enamel, fused onto metal through a controlled firing process, offers superior durability and resistance to chipping compared to direct-on enamel, which is applied as a raw powder and fused directly. The controlled application in fritted enamel enhances bonding strength, resulting in improved resistance to corrosion, thermal shock, and mechanical wear. Direct-on enamel may provide a smoother finish but generally exhibits lower long-term performance under harsh environmental conditions than fritted enamel.

Visual Aesthetics: Color, Texture, and Finish

Fritted enamel offers a smooth, uniform surface with rich, vibrant colors achieved by fusing powdered glass onto the metal, resulting in a glossy, durable finish that resists chipping and fading. Direct-on enamel provides a more textured, matte appearance due to its application method, which can highlight the underlying metal and create varied visual effects. Color depth in fritted enamel tends to be more consistent and intense, while direct-on enamel allows for greater artistic variation in texture and finish.

Applications and Industry Use Cases

Fritted enamel, consisting of powdered glass fused onto a metal substrate, excels in industrial applications requiring enhanced durability and corrosion resistance, such as cookware, kitchen appliances, and architectural panels. Direct-on enamel, which bonds directly without a frit layer, is favored in automotive and electrical industries for its cost-effectiveness and ability to produce smooth, glossy finishes on steel components. Both enamel types serve distinct purposes across manufacturing sectors, with fritted enamel suited for heavy-duty, high-wear environments and direct-on enamel preferred in decorative or functional coatings demanding efficient production.

Cost Implications and Economic Considerations

Fritted enamel involves applying a glassy frit layer before the final enamel coat, increasing production costs due to additional materials and processing steps. Direct-on enamel reduces manufacturing expenses by eliminating the frit application, making it more cost-effective for large-scale production. Economic considerations favor fritted enamel for premium products requiring enhanced durability, while direct-on enamel suits budget-friendly applications with faster throughput.

Environmental Impact and Sustainability

Fritted enamel, produced by fusing powdered glass onto metal at high temperatures, offers superior durability and recyclability compared to direct-on enamel, which is applied as a liquid and often requires multiple coatings with higher energy consumption. Fritted enamel's lower emission profile during manufacturing and its longer lifespan contribute to reduced environmental impact and enhanced sustainability. Choosing fritted enamel supports resource efficiency and waste reduction, aligning with eco-friendly production standards.

Choosing the Right Enamel: Factors to Consider

Choosing the right enamel depends on the specific application requirements, including durability, adhesion, and resistance to high temperatures. Fritted enamel offers superior durability and chemical resistance due to its glassy, bonded surface, making it ideal for cookware and industrial equipment, whereas direct-on enamel is better suited for applications needing quicker application and lower firing temperatures. Evaluating factors like substrate compatibility, thermal expansion, and desired finish quality ensures optimal performance and longevity for the chosen enamel type.

Fritted enamel vs Direct-on enamel Infographic

materialdif.com

materialdif.com