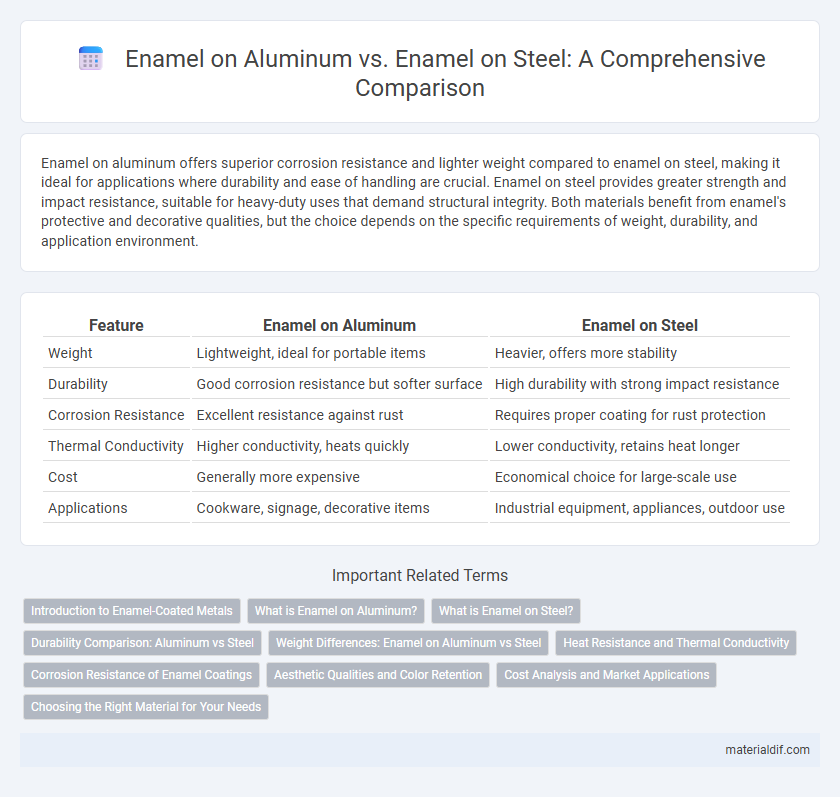

Enamel on aluminum offers superior corrosion resistance and lighter weight compared to enamel on steel, making it ideal for applications where durability and ease of handling are crucial. Enamel on steel provides greater strength and impact resistance, suitable for heavy-duty uses that demand structural integrity. Both materials benefit from enamel's protective and decorative qualities, but the choice depends on the specific requirements of weight, durability, and application environment.

Table of Comparison

| Feature | Enamel on Aluminum | Enamel on Steel |

|---|---|---|

| Weight | Lightweight, ideal for portable items | Heavier, offers more stability |

| Durability | Good corrosion resistance but softer surface | High durability with strong impact resistance |

| Corrosion Resistance | Excellent resistance against rust | Requires proper coating for rust protection |

| Thermal Conductivity | Higher conductivity, heats quickly | Lower conductivity, retains heat longer |

| Cost | Generally more expensive | Economical choice for large-scale use |

| Applications | Cookware, signage, decorative items | Industrial equipment, appliances, outdoor use |

Introduction to Enamel-Coated Metals

Enamel-coated metals combine a glassy, durable surface with a metal base, enhancing corrosion resistance and aesthetic appeal. Enamel on aluminum offers lightweight properties and superior heat resistance, ideal for cookware and signage, while enamel on steel provides increased strength and impact resistance, commonly used in appliances and automotive parts. Both materials ensure a smooth, protective coating that prevents rust and maintains color vibrancy over time.

What is Enamel on Aluminum?

Enamel on aluminum consists of a durable glassy coating fused directly onto an aluminum substrate, providing corrosion resistance and a smooth, glossy finish ideal for decorative and protective applications. This process involves applying powdered glass and firing it at high temperatures to create a strong bond, enhancing aluminum's lightweight properties with added hardness and weather resistance. Compared to steel, enamel on aluminum offers superior resistance to rust and a lighter weight while maintaining comparable aesthetic appeal and durability.

What is Enamel on Steel?

Enamel on steel is a coating process that fuses powdered glass to a steel substrate at high temperatures, creating a durable, corrosion-resistant, and heat-resistant surface. This enamel layer provides excellent protection against chemicals and weathering, making it ideal for cookware, appliances, and architectural panels. Compared to aluminum, enamel on steel offers superior hardness and impact resistance, enhancing the longevity of coated products.

Durability Comparison: Aluminum vs Steel

Enamel on steel offers superior durability compared to aluminum due to steel's higher tensile strength and resistance to impact damage. Aluminum, while lighter and corrosion-resistant, is more prone to denting and surface abrasion, which can compromise the enamel coating over time. For applications requiring long-lasting wear and structural integrity, enamel on steel provides more robust performance under harsh conditions.

Weight Differences: Enamel on Aluminum vs Steel

Enamel on aluminum results in a significantly lighter product compared to enamel on steel due to aluminum's lower density, approximately 2.7 g/cm3 versus steel's 7.85 g/cm3. This weight difference enhances ease of handling and reduces transportation costs for enamel-coated aluminum items. Despite the weight savings, enamel adhesion quality remains robust on both metals, ensuring durability.

Heat Resistance and Thermal Conductivity

Enamel on aluminum offers superior thermal conductivity, allowing faster heat transfer and more efficient temperature regulation, but it generally has lower heat resistance compared to enamel on steel. Enamel-coated steel withstands higher temperatures without degrading, making it ideal for applications involving prolonged exposure to intense heat. Selecting between enamel on aluminum or steel depends on the specific balance required between heat dissipation and resistance in industrial or cookware uses.

Corrosion Resistance of Enamel Coatings

Enamel coatings on aluminum exhibit superior corrosion resistance due to aluminum's natural oxide layer, which enhances adhesion and prevents moisture ingress more effectively than steel substrates. Enamel on steel can be prone to corrosion if the coating is compromised, as steel lacks this protective oxide barrier and can rust upon exposure to water and oxygen. The durability of enamel coatings on aluminum makes them ideal for environments with high humidity or chemical exposure, ensuring longer-lasting protection.

Aesthetic Qualities and Color Retention

Enamel on aluminum offers superior color retention due to its non-porous surface, resulting in vibrant and long-lasting finishes that resist fading and discoloration. Enamel coatings on steel provide a robust matte or glossy appearance but may show signs of wear and color dullness over time when exposed to harsh environmental conditions. The lightweight nature of aluminum combined with enamel enhances aesthetic appeal without sacrificing durability, making it ideal for applications demanding vivid, enduring colors.

Cost Analysis and Market Applications

Enamel on aluminum generally offers a lightweight and corrosion-resistant finish but tends to incur higher production costs due to specialized surface preparation and lower thermal conductivity compared to enamel on steel. Enamel on steel is more cost-effective for large-scale applications, providing durability and better adhesion at a reduced material expense, making it ideal for heavy-duty industrial and construction use. Market applications favor enamel on aluminum for specialized products requiring weight savings and aesthetic appeal, whereas enamel on steel dominates sectors prioritizing strength and cost efficiency, such as appliances and infrastructure.

Choosing the Right Material for Your Needs

Enamel on aluminum offers lightweight durability and excellent corrosion resistance, making it ideal for outdoor and mobile applications where weight reduction is crucial. Enamel on steel provides superior strength and impact resistance, suited for high-traffic or industrial environments requiring robust protection. Selecting between enamel on aluminum or steel depends on balancing factors like weight, durability demands, and environmental exposure.

Enamel on Aluminum vs Enamel on Steel Infographic

materialdif.com

materialdif.com