Silica flux promotes a smooth, glassy finish in enamel by lowering the melting point and enhancing durability, making it ideal for high-temperature firings. Borax flux, on the other hand, facilitates better adhesion and flow of the enamel, reducing bubbles and imperfections during firing. Each flux type influences enamel's texture and color vibrancy, requiring careful selection based on desired visual and physical properties.

Table of Comparison

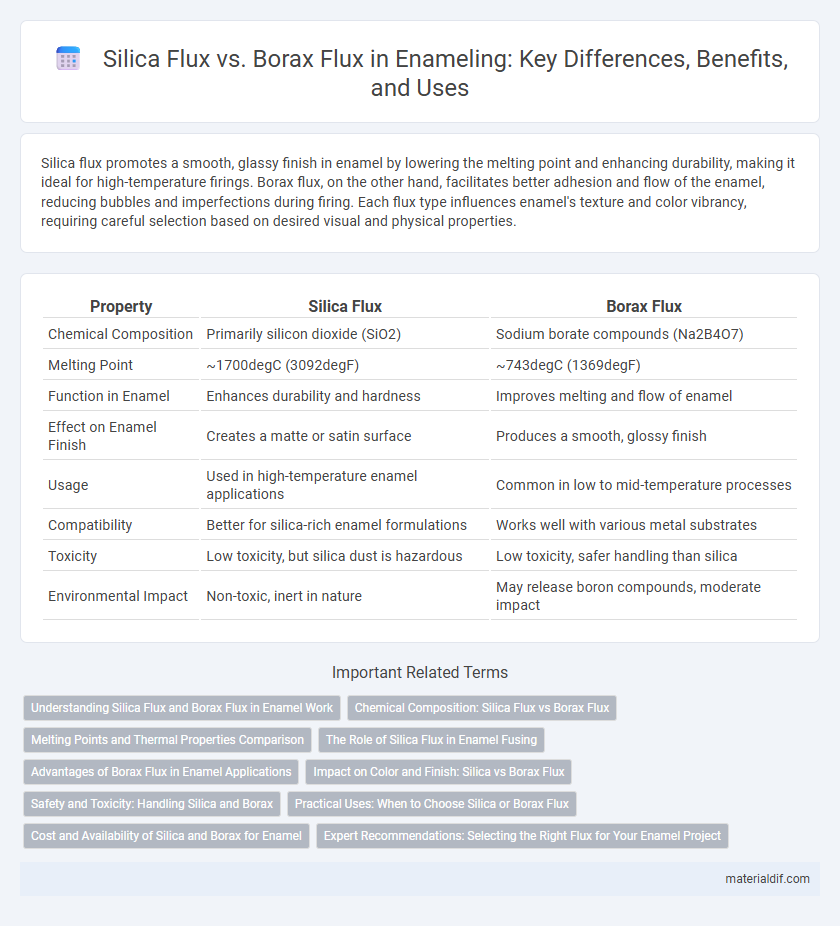

| Property | Silica Flux | Borax Flux |

|---|---|---|

| Chemical Composition | Primarily silicon dioxide (SiO2) | Sodium borate compounds (Na2B4O7) |

| Melting Point | ~1700degC (3092degF) | ~743degC (1369degF) |

| Function in Enamel | Enhances durability and hardness | Improves melting and flow of enamel |

| Effect on Enamel Finish | Creates a matte or satin surface | Produces a smooth, glossy finish |

| Usage | Used in high-temperature enamel applications | Common in low to mid-temperature processes |

| Compatibility | Better for silica-rich enamel formulations | Works well with various metal substrates |

| Toxicity | Low toxicity, but silica dust is hazardous | Low toxicity, safer handling than silica |

| Environmental Impact | Non-toxic, inert in nature | May release boron compounds, moderate impact |

Understanding Silica Flux and Borax Flux in Enamel Work

Silica flux and borax flux play crucial roles in enamel work, influencing the melting behavior and final texture of the enamel. Silica flux acts as a glass former, providing hardness and durability to the enamel surface, while borax flux lowers the melting point, promoting better flow and adhesion of the enamel to metal substrates. Understanding the balance between silica's structural contribution and borax's fluxing properties is essential for achieving optimal enamel quality and smooth finishes.

Chemical Composition: Silica Flux vs Borax Flux

Silica flux primarily consists of silicon dioxide (SiO2), which helps lower the melting point of the enamel and improves its hardness and durability. Borax flux contains sodium borate compounds that facilitate better flow and fusion of the enamel at lower temperatures, enhancing the smoothness and gloss of the final surface. The chemical composition differences between silica and borax fluxes directly influence the enamel's melting behavior, texture, and overall finish quality.

Melting Points and Thermal Properties Comparison

Silica flux has a higher melting point around 1710degC, offering greater thermal stability in enamel applications, while borax flux melts at approximately 743degC, providing a lower-temperature melting option for easier glass fusion. Silica's thermal properties enable it to withstand prolonged high temperatures without breaking down, making it suitable for durable, high-temperature enameling. In contrast, borax flux lowers the melting point of the glass mixture, facilitating smoother flow and adhesion during firing but with less resistance to thermal shock.

The Role of Silica Flux in Enamel Fusing

Silica flux acts as a crucial component in enamel fusing by lowering the melting point of silica, thus facilitating the formation of a smooth, glassy surface on metal substrates. Its ability to promote strong chemical bonding between the enamel and metal enhances durability and resistance to thermal shock. In comparison to borax flux, silica flux provides improved hardness and corrosion resistance in the final enamel coating.

Advantages of Borax Flux in Enamel Applications

Borax flux offers superior melting properties compared to silica flux, enabling lower firing temperatures in enamel applications which protects delicate substrates. It provides excellent wetting and adhesion to metal surfaces, ensuring a smooth, durable enamel finish with enhanced resistance to chipping and corrosion. Its chemical stability during firing reduces defects such as bubbles and blisters, improving overall enamel quality and longevity.

Impact on Color and Finish: Silica vs Borax Flux

Silica flux enhances enamel's transparency and brilliance, producing a glass-like finish with vibrant color clarity that intensifies underlying pigments. Borax flux facilitates melting at lower temperatures, resulting in a smoother, more opaque finish with muted color saturation and a softer surface texture. Choice between silica and borax flux directly influences enamel's final aesthetic, with silica emphasizing brightness and borax favoring a matte, subdued appearance.

Safety and Toxicity: Handling Silica and Borax

Silica flux poses lower toxicity risks but can cause respiratory issues if inhaled as fine dust during handling, necessitating proper ventilation and protective masks. Borax flux, while effective in lowering melting points, carries higher toxicity concerns, including skin irritation and potential reproductive effects, requiring gloves and careful handling to avoid exposure. Both fluxes demand adherence to safety guidelines to minimize health hazards during enamel firing processes.

Practical Uses: When to Choose Silica or Borax Flux

Silica flux is ideal for high-temperature enameling and complex glass compositions, providing strong adhesion and durability on metals like steel and cast iron. Borax flux works best for lower melting points and delicate substrates such as copper and brass, ensuring smooth surface finishes with less risk of oxidation. Choose silica flux for robust, high-wear applications and borax flux for fine detail work requiring controlled melting and reduced thermal stress.

Cost and Availability of Silica and Borax for Enamel

Silica flux is generally more cost-effective due to its abundant availability in the Earth's crust, making it a preferred choice for large-scale enamel production. Borax flux, while effective in lowering melting temperatures, tends to be more expensive and less readily available, often sourced from specific mining regions. This scarcity and higher cost can impact project budgets, especially in industrial enamel applications where flux quantity is substantial.

Expert Recommendations: Selecting the Right Flux for Your Enamel Project

Experts recommend choosing silica flux for enamel projects requiring higher fusion points and increased durability, as it enhances hardness and wear resistance. Borax flux is preferred for lower melting temperatures, providing ease of application and smoother finishes ideal for delicate or detailed work. Selecting the right flux depends on balancing thermal properties with desired enamel texture and project specifications.

Silica flux vs borax flux Infographic

materialdif.com

materialdif.com