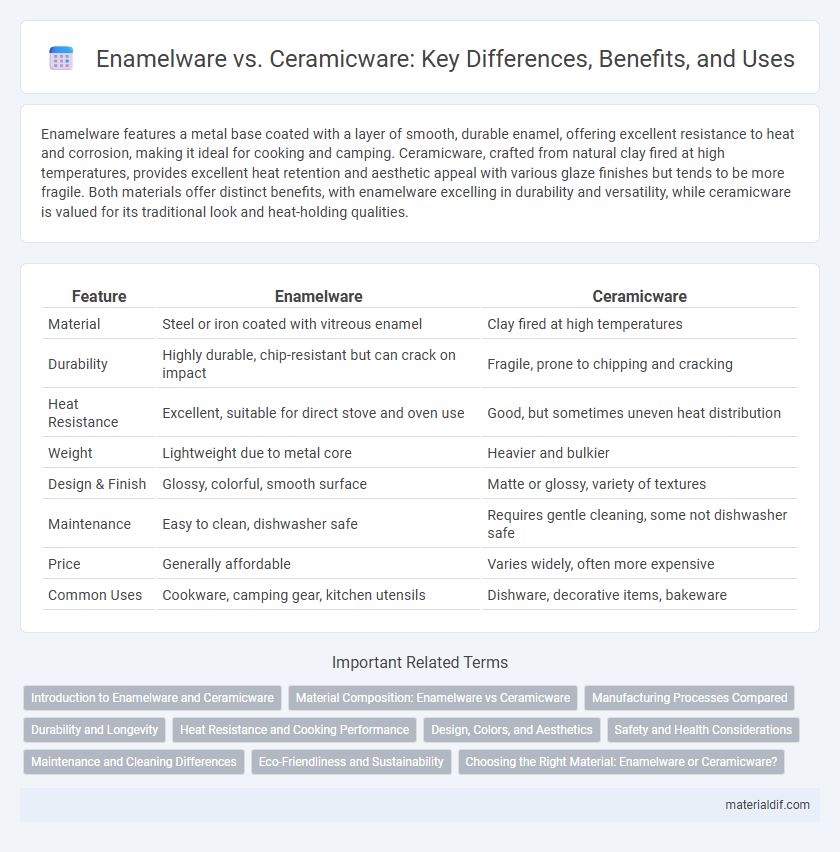

Enamelware features a metal base coated with a layer of smooth, durable enamel, offering excellent resistance to heat and corrosion, making it ideal for cooking and camping. Ceramicware, crafted from natural clay fired at high temperatures, provides excellent heat retention and aesthetic appeal with various glaze finishes but tends to be more fragile. Both materials offer distinct benefits, with enamelware excelling in durability and versatility, while ceramicware is valued for its traditional look and heat-holding qualities.

Table of Comparison

| Feature | Enamelware | Ceramicware |

|---|---|---|

| Material | Steel or iron coated with vitreous enamel | Clay fired at high temperatures |

| Durability | Highly durable, chip-resistant but can crack on impact | Fragile, prone to chipping and cracking |

| Heat Resistance | Excellent, suitable for direct stove and oven use | Good, but sometimes uneven heat distribution |

| Weight | Lightweight due to metal core | Heavier and bulkier |

| Design & Finish | Glossy, colorful, smooth surface | Matte or glossy, variety of textures |

| Maintenance | Easy to clean, dishwasher safe | Requires gentle cleaning, some not dishwasher safe |

| Price | Generally affordable | Varies widely, often more expensive |

| Common Uses | Cookware, camping gear, kitchen utensils | Dishware, decorative items, bakeware |

Introduction to Enamelware and Ceramicware

Enamelware consists of steel or iron coated with a durable layer of porcelain enamel, offering excellent heat distribution and resistance to scratches and stains, making it ideal for cookware and kitchen utensils. Ceramicware is made from clay fired at high temperatures, providing a naturally non-reactive, heat-retentive surface often used in bakeware and decorative dishes. Both materials emphasize durability and heat management but differ in composition and typical applications, with enamelware favored for rugged use and ceramicware for aesthetic and insulating properties.

Material Composition: Enamelware vs Ceramicware

Enamelware features a metal base typically made of steel or cast iron coated with a layer of vitreous enamel, creating a durable, non-porous surface resistant to rust and staining. Ceramicware consists primarily of natural clay or earthenware fired at high temperatures, forming a porous but often glazed material that offers heat retention but can chip or crack more easily. The differing material compositions influence weight, durability, heat conduction, and resistance to chemical reactions in culinary and decorative applications.

Manufacturing Processes Compared

Enamelware manufacturing involves fusing powdered glass to a metal substrate through high-temperature firing, resulting in a durable, non-porous coating resistant to corrosion and staining. Ceramicware production entails shaping clay materials, often mixed with minerals like kaolin, followed by glazing and kiln-firing at high temperatures to achieve hardness and vitrification. Both processes require precision temperature control, but enamelware emphasizes metallurgical bonding, while ceramicware relies on clay mineral transformation and glaze maturation.

Durability and Longevity

Enamelware exhibits superior durability due to its metal core coated with a fused glass layer, offering resistance to chipping, cracking, and thermal shock compared to ceramicware's brittle composition. Ceramicware, while often praised for its aesthetic appeal, tends to be more susceptible to damage from impact and rapid temperature changes, reducing its longevity. The long-lasting nature of enamelware makes it ideal for heavy use in both kitchen and outdoor settings.

Heat Resistance and Cooking Performance

Enamelware offers superior heat resistance due to its durable glass coating fused to metal, enabling even heat distribution and rapid temperature changes without cracking. Ceramicware retains heat longer, providing consistent cooking temperatures, but is more susceptible to thermal shock and cracking under sudden temperature shifts. For high-heat cooking and quick temperature adjustments, enamelware outperforms ceramicware in durability and performance.

Design, Colors, and Aesthetics

Enamelware offers vibrant, glossy finishes with a wide range of bold colors and smooth surfaces that resist staining and scratches, making it ideal for modern, colorful kitchen aesthetics. Ceramicware boasts intricate patterns and matte or glazed textures, providing a classic, artisanal look with subtle variations in color due to its handcrafted nature. While enamelware emphasizes sleek, uniform designs suited for contemporary decor, ceramicware delivers warmth and uniqueness through its traditional craftsmanship and diverse finishes.

Safety and Health Considerations

Enamelware features a durable glass coating fused to metal that resists chipping and corrosion, making it non-reactive and safe for cooking acidic foods without leaching harmful substances. Ceramicware, often porous unless properly glazed, may harbor bacteria if the glaze cracks and can sometimes contain lead or cadmium, posing potential health risks. For optimal safety, choose high-quality, lead-free glazed ceramicware or thoroughly inspected enamelware certified for food use.

Maintenance and Cleaning Differences

Enamelware offers a smooth, non-porous surface that resists stains and is easy to clean with mild detergents, making it less prone to retaining odors or food particles compared to ceramicware. Ceramicware, having a porous glaze, may require more careful cleaning to avoid staining and often demands gentle handling to prevent chipping or cracking during maintenance. Enamelware's durability allows it to withstand abrasive scrubbing and dishwasher use, while ceramicware typically benefits from hand washing and softer cleaning tools to maintain its finish.

Eco-Friendliness and Sustainability

Enamelware is often considered more eco-friendly than ceramicware due to its durability, resistance to chipping, and ability to be recycled, reducing landfill waste. Ceramicware production typically involves higher energy consumption and emits more CO2 during kiln firing processes. Choosing enamelware supports sustainability efforts by promoting long-lasting kitchen products with lower environmental impact.

Choosing the Right Material: Enamelware or Ceramicware?

Enamelware offers superior durability and heat resistance, making it ideal for outdoor cooking and heavy-duty use, while ceramicware provides better heat retention and aesthetic appeal, suitable for indoor dining and decorative purposes. The non-porous surface of enamelware resists stains and odors, ensuring easy maintenance compared to the more fragile, porous ceramicware that can chip or crack. Selecting between enamelware and ceramicware depends on usage preferences, with enamelware excelling in practicality and ceramicware in elegance.

Enamelware vs Ceramicware Infographic

materialdif.com

materialdif.com