Enamel frit is a pre-melted and cooled glass material that offers consistent composition and ease of application, making it ideal for industrial processes and uniform coatings. Enamel powder, on the other hand, is typically ground glass used for more detailed or artistic work, allowing for varied textures and finishes. Choosing between enamel frit and enamel powder depends on the project's precision requirements and surface characteristics.

Table of Comparison

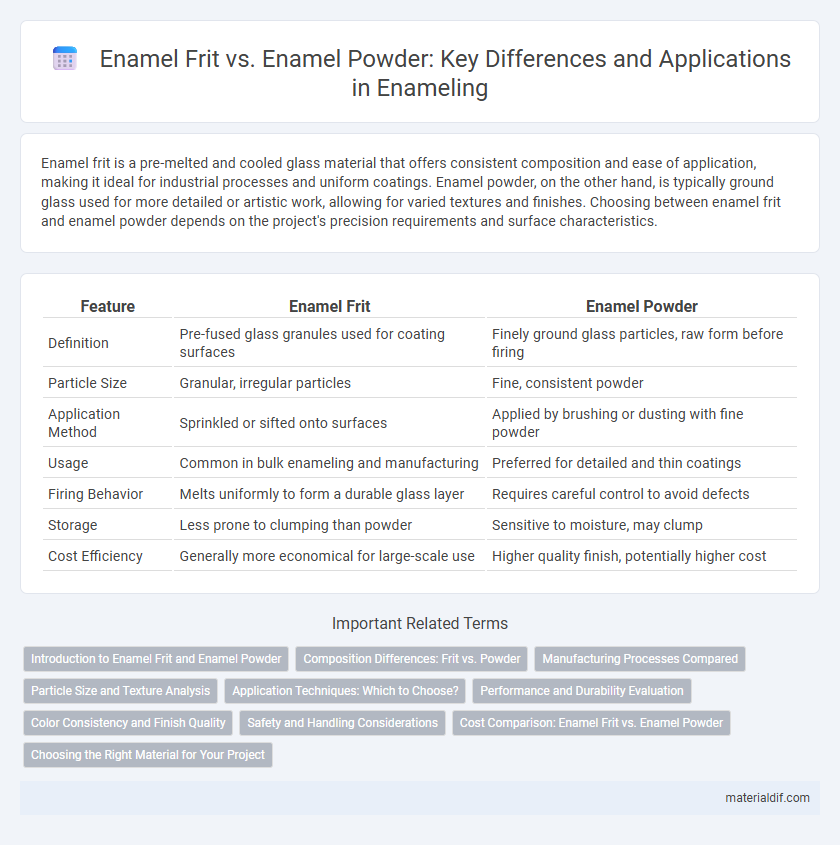

| Feature | Enamel Frit | Enamel Powder |

|---|---|---|

| Definition | Pre-fused glass granules used for coating surfaces | Finely ground glass particles, raw form before firing |

| Particle Size | Granular, irregular particles | Fine, consistent powder |

| Application Method | Sprinkled or sifted onto surfaces | Applied by brushing or dusting with fine powder |

| Usage | Common in bulk enameling and manufacturing | Preferred for detailed and thin coatings |

| Firing Behavior | Melts uniformly to form a durable glass layer | Requires careful control to avoid defects |

| Storage | Less prone to clumping than powder | Sensitive to moisture, may clump |

| Cost Efficiency | Generally more economical for large-scale use | Higher quality finish, potentially higher cost |

Introduction to Enamel Frit and Enamel Powder

Enamel frit and enamel powder are fundamental forms of vitreous enamel used in various industrial and artistic applications. Enamel frit is a pre-melted, granulated glass that offers improved consistency and fewer impurities compared to raw enamel powder, which is finely ground glass used directly in enameling processes. The choice between enamel frit and enamel powder affects the melting behavior, finish quality, and durability of the final enamel coating.

Composition Differences: Frit vs. Powder

Enamel frit consists of raw materials that have been melted, rapidly cooled, and then crushed into granules, resulting in a stable, homogenized mixture with reduced reactivity and improved durability. Enamel powder, in contrast, comprises finely ground raw materials that have not undergone melting, maintaining higher reactivity and a more variable composition, which can affect firing behavior. The compositional differences influence melting points, surface finish, and compatibility with substrates in enamel applications.

Manufacturing Processes Compared

Enamel frit undergoes a controlled melting and rapid cooling process that produces a glassy, granulated material, ensuring consistent particle size and purity ideal for industrial applications. Enamel powder, typically derived from grinding frit, may vary in particle size and requires additional sieving to achieve uniformity, impacting the application quality and firing behavior. Manufacturing differences influence melting points, surface finish, and adhesion properties critical for durability in coatings and artistic uses.

Particle Size and Texture Analysis

Enamel frit typically features larger, more uniform particle sizes compared to enamel powder, which has finer, irregular granules that enhance surface smoothness and shading consistency. Particle size distribution significantly affects melting behavior, with enamel frit providing controlled fusion and enamel powder offering faster melting rates due to increased surface area. Texture analysis reveals that enamel powder yields a more even coating on substrates, improving adhesion and minimizing defects in the final enamel finish.

Application Techniques: Which to Choose?

Enamel frit offers superior control and consistency for kiln fusing and glasswork due to its pre-melted, granulated form, enabling smoother application and uniform melting compared to enamel powder. Enamel powder is preferable for detailed work requiring fine layering or airbrushing, as its fine particles adhere better to surfaces and allow for intricate designs. Choosing between enamel frit and powder depends on the desired finish, thickness, and application method, with frit suited for even coverage and powder ideal for precision techniques.

Performance and Durability Evaluation

Enamel frit offers enhanced performance and durability due to its pre-melted, granulated composition that ensures uniform melting and better adhesion on surfaces compared to enamel powder. The controlled particle size and homogeneity of enamel frit result in consistent coating thickness, improved resistance to chipping, and superior long-term wear under thermal stress. Enamel powder, often requiring higher firing temperatures and prone to uneven melting, may exhibit reduced mechanical strength and increased susceptibility to surface degradation.

Color Consistency and Finish Quality

Enamel frit offers superior color consistency compared to enamel powder because it is partially fused during manufacture, ensuring uniform particle size and predictable melting behavior that produce a smooth, even finish. Enamel powder, being more granular and less processed, can lead to color variations and uneven textures after firing. The controlled melting characteristics of enamel frit result in a high-quality, glossy finish that is preferred for precision applications and decorative coatings.

Safety and Handling Considerations

Enamel frit offers enhanced safety due to its pre-melted and cooled glass form, reducing dust inhalation hazards compared to enamel powder, which can release fine particles prone to respiratory risks during handling. Proper personal protective equipment (PPE), such as masks and gloves, should be utilized when working with enamel powders to prevent skin irritation and inhalation of silica dust. Storage conditions for both materials require dry environments to prevent clumping and degradation, but enamel powders demand more cautious ventilation protocols to limit airborne particulate exposure.

Cost Comparison: Enamel Frit vs. Enamel Powder

Enamel frit generally offers a cost advantage over enamel powder due to its pre-melted and granulated form, which reduces processing time and energy consumption during application. Enamel powder often requires more extensive handling and higher temperatures to achieve the same melting quality, increasing overall production costs. Industrial users favor enamel frit for large-scale projects where efficiency and cost-effectiveness are critical factors.

Choosing the Right Material for Your Project

Enamel frit offers a consistent, pre-melted glass composition that ensures uniform color and texture, making it ideal for projects requiring precise results. Enamel powder provides greater versatility and faster melting but demands careful handling to avoid uneven coverage or warping. Selecting between enamel frit and powder depends on factors such as project complexity, firing temperature, and desired finish quality.

Enamel frit vs enamel powder Infographic

materialdif.com

materialdif.com