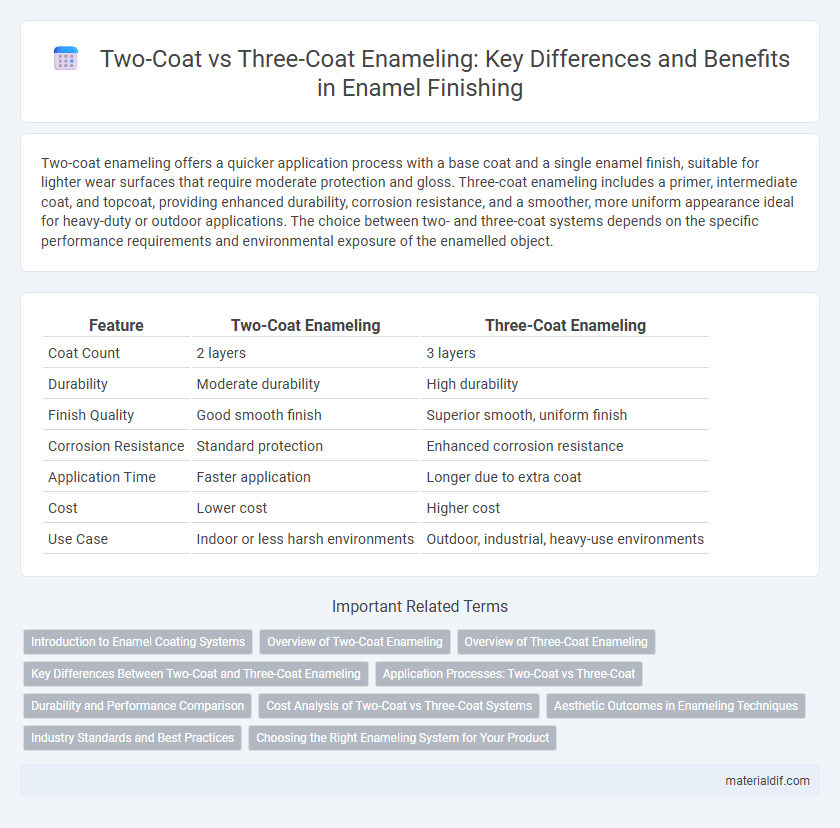

Two-coat enameling offers a quicker application process with a base coat and a single enamel finish, suitable for lighter wear surfaces that require moderate protection and gloss. Three-coat enameling includes a primer, intermediate coat, and topcoat, providing enhanced durability, corrosion resistance, and a smoother, more uniform appearance ideal for heavy-duty or outdoor applications. The choice between two- and three-coat systems depends on the specific performance requirements and environmental exposure of the enamelled object.

Table of Comparison

| Feature | Two-Coat Enameling | Three-Coat Enameling |

|---|---|---|

| Coat Count | 2 layers | 3 layers |

| Durability | Moderate durability | High durability |

| Finish Quality | Good smooth finish | Superior smooth, uniform finish |

| Corrosion Resistance | Standard protection | Enhanced corrosion resistance |

| Application Time | Faster application | Longer due to extra coat |

| Cost | Lower cost | Higher cost |

| Use Case | Indoor or less harsh environments | Outdoor, industrial, heavy-use environments |

Introduction to Enamel Coating Systems

Two-coat enameling systems typically include a basecoat and a topcoat, providing basic protection and a smooth finish suitable for less demanding applications. Three-coat enameling systems add an intermediate coat, enhancing durability, corrosion resistance, and aesthetic depth, making them ideal for harsher environments and premium finishes. Selecting between two-coat and three-coat enamel coatings depends on factors like exposure conditions, budget constraints, and desired longevity of the coated surface.

Overview of Two-Coat Enameling

Two-coat enameling involves applying a base coat followed by a top enamel layer, offering effective protection and a smooth, glossy finish. This method ensures durability and resistance to corrosion, making it suitable for various metal surfaces in industrial and decorative applications. Compared to three-coat enameling, two-coat enameling is more cost-efficient and faster while still maintaining strong adhesion and aesthetic appeal.

Overview of Three-Coat Enameling

Three-coat enameling involves the application of a ground coat, a covering coat, and a final polish coat, delivering enhanced durability and a smoother finish compared to two-coat enameling. This multi-layer approach improves corrosion resistance and provides superior protection against chipping and wear. The increased thickness and uniformity of the enamel layers make three-coat enameling ideal for metal surfaces exposed to harsh environmental conditions.

Key Differences Between Two-Coat and Three-Coat Enameling

Two-coat enameling involves applying a base coat and a top coat, providing adequate coverage and durability for less demanding surfaces. Three-coat enameling adds an intermediate coat between the base and top coats, enhancing adhesion, corrosion resistance, and overall finish quality. The extra layer in three-coat enameling results in increased protection, making it ideal for harsh environments or heavy-use applications.

Application Processes: Two-Coat vs Three-Coat

Two-coat enameling involves applying a base coat followed by a single enamel topcoat, offering a quicker and more cost-effective process primarily used for less demanding surfaces. Three-coat enameling incorporates a base coat, an intermediate coat, and a final topcoat, providing enhanced durability, corrosion resistance, and a smoother finish ideal for industrial applications. The three-coat process requires longer curing times between coats but results in superior protection and aesthetic quality compared to two-coat enameling.

Durability and Performance Comparison

Two-coat enameling offers adequate protection with a base coat and a single topcoat, providing moderate durability for general applications. In contrast, three-coat enameling includes an additional intermediate layer that enhances resistance to chipping, corrosion, and wear, significantly extending the lifespan of the coated surface. The extra layer in three-coat enameling also improves adhesion and enables better performance in harsh environments, making it ideal for industrial and high-traffic uses.

Cost Analysis of Two-Coat vs Three-Coat Systems

Two-coat enameling systems typically reduce material and labor costs by applying a single base coat and one topcoat, making them more cost-effective for projects with budget constraints and moderate durability requirements. Three-coat enameling, involving a basecoat, intermediate coat, and topcoat, increases expenses due to additional materials and extended application time but offers superior corrosion resistance and longer lifespan. Cost analysis shows that while two-coat systems save up to 25-30% initially, three-coat systems provide better long-term value by decreasing maintenance and replacement frequency.

Aesthetic Outcomes in Enameling Techniques

Two-coat enameling provides a smooth, glossy finish with strong color saturation, ideal for simpler designs requiring vibrant aesthetics. Three-coat enameling enhances depth and richness in color while improving surface durability and texture complexity, often preferred for intricate and high-end decorative pieces. The additional layer in three-coat enameling allows for greater control over color gradients and visual effects, resulting in superior aesthetic outcomes compared to two-coat techniques.

Industry Standards and Best Practices

Two-coat enameling typically involves a base coat and a top coat, meeting basic industry standards for corrosion resistance and durability in general applications. Three-coat enameling, incorporating an additional intermediate coat, aligns with best practices for enhanced adhesion, increased protection, and superior finish quality, especially in heavy-duty or high-performance environments. Industry standards such as ISO 4532 emphasize multi-layer enamel systems to optimize longevity and chemical resistance in industrial settings.

Choosing the Right Enameling System for Your Product

Selecting the appropriate enameling system depends on the product's durability requirements and aesthetic goals. Two-coat enameling offers a practical solution for items needing moderate protection and smooth finishes, combining a single base coat with a single topcoat. Three-coat enameling incorporates an additional coat, enhancing corrosion resistance and color depth, ideal for heavy-duty or long-lasting applications.

Two-Coat Enameling vs Three-Coat Enameling Infographic

materialdif.com

materialdif.com