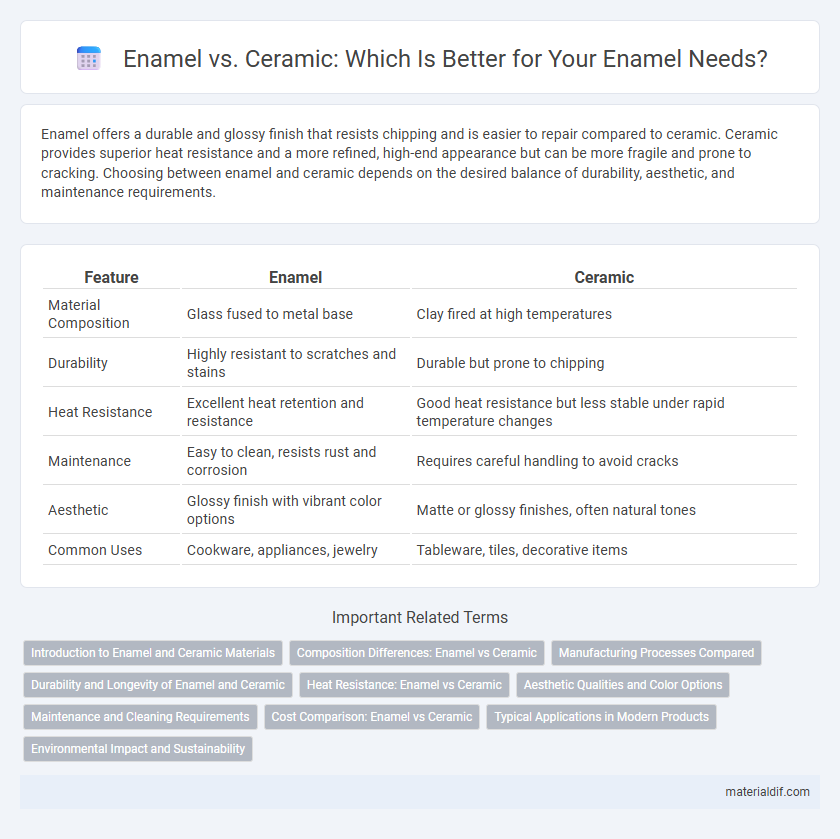

Enamel offers a durable and glossy finish that resists chipping and is easier to repair compared to ceramic. Ceramic provides superior heat resistance and a more refined, high-end appearance but can be more fragile and prone to cracking. Choosing between enamel and ceramic depends on the desired balance of durability, aesthetic, and maintenance requirements.

Table of Comparison

| Feature | Enamel | Ceramic |

|---|---|---|

| Material Composition | Glass fused to metal base | Clay fired at high temperatures |

| Durability | Highly resistant to scratches and stains | Durable but prone to chipping |

| Heat Resistance | Excellent heat retention and resistance | Good heat resistance but less stable under rapid temperature changes |

| Maintenance | Easy to clean, resists rust and corrosion | Requires careful handling to avoid cracks |

| Aesthetic | Glossy finish with vibrant color options | Matte or glossy finishes, often natural tones |

| Common Uses | Cookware, appliances, jewelry | Tableware, tiles, decorative items |

Introduction to Enamel and Ceramic Materials

Enamel is a durable, glass-like coating fused onto metal surfaces through high-temperature firing, providing corrosion resistance and a smooth, glossy finish. Ceramic materials consist of inorganic, non-metallic solids processed at high temperatures, known for their hardness, heat resistance, and electrical insulation properties. Both enamel and ceramic offer unique advantages in durability and aesthetics, with enamel excelling in protective coatings and ceramics widely used in structural and electronic applications.

Composition Differences: Enamel vs Ceramic

Enamel consists primarily of powdered glass fused to a substrate through high-temperature firing, creating a smooth, glossy surface with strong adhesion to metals. Ceramic is composed of inorganic, non-metallic materials like clay, kaolin, and silica, which are shaped and hardened through firing at varying temperatures to achieve different textures and durability. The key composition difference lies in enamel's glass-based coating versus ceramic's structurally fired clay matrix, influencing their respective finish, strength, and application uses.

Manufacturing Processes Compared

Enamel manufacturing involves fusing powdered glass onto a metal substrate through high-temperature firing, creating a durable, glossy coating resistant to corrosion and heat. Ceramic production typically uses shaped clay or other inorganic materials that are kiln-fired at high temperatures to achieve hardness and thermal stability without a metallic base. The enamel process emphasizes adhesion and surface coating on metals, whereas ceramic manufacturing focuses on forming solid, standalone structures through sintering and vitrification.

Durability and Longevity of Enamel and Ceramic

Enamel offers excellent durability due to its glass-like coating, which resists scratches, stains, and heat, making it highly resilient in kitchen and dental applications. Ceramic, while also durable, can be more prone to chipping and cracking under impact compared to enamel's robust surface. The longevity of enamel surfaces often surpasses ceramics because enamel maintains its finish and strength over time with proper care.

Heat Resistance: Enamel vs Ceramic

Enamel demonstrates superior heat resistance compared to ceramic, withstanding temperatures up to 1,400degF without degradation. Ceramic materials typically tolerate heat up to around 2,300degF, but their thermal shock resistance is lower, making them more prone to cracking under rapid temperature changes. Enamel's durable, glass-like coating offers enhanced protection against heat-induced damage, ideal for cookware and industrial applications requiring consistent high-temperature exposure.

Aesthetic Qualities and Color Options

Enamel offers a vibrant, glossy finish with rich, saturated colors that resist fading, making it ideal for bold and eye-catching designs, whereas ceramic tends to provide a more muted, matte appearance with subtle color variations. The color palette of enamel spans a wide spectrum from bright primary shades to deep, intense hues, giving designers greater flexibility in achieving standout visual effects. Ceramic's aesthetic appeal lies in its natural, earthy tones and textured surfaces, which complement minimalist and rustic styles but limit high-gloss or vivid color choices.

Maintenance and Cleaning Requirements

Enamel surfaces require gentle cleaning with non-abrasive, mild detergents to prevent scratches and preserve their glossy finish, whereas ceramic is more resistant to stains and can tolerate harsher cleaning agents. Enamel's smooth texture demands regular wiping to avoid build-up of grime and maintain its shine, while ceramic's porous nature necessitates periodic sealing and thorough cleaning to prevent dirt infiltration. Both materials benefit from avoiding metal scouring pads, but enamel generally demands more delicate care to sustain its aesthetic qualities.

Cost Comparison: Enamel vs Ceramic

Enamel cookware typically costs less than ceramic cookware due to its simpler manufacturing process and widespread availability, making it an economical choice for budget-conscious consumers. Ceramic cookware often carries a higher price tag, reflecting its aesthetic appeal, durability, and non-reactive surface. For cost-efficiency, enamel offers solid performance at a lower price point, while ceramic may justify its premium with enhanced design and non-stick properties.

Typical Applications in Modern Products

Enamel is commonly used in cookware, jewelry, and signage due to its durable, glossy finish and resistance to heat and corrosion. Ceramic finds typical applications in tiles, dental restorations, and electronic insulators, valued for its hardness, thermal stability, and electrical insulation properties. Enamel coatings enhance metal substrates' aesthetics and protection, while ceramics serve primarily as structural and functional materials in modern products.

Environmental Impact and Sustainability

Enamel coatings are made from natural raw materials like silica, soda ash, and metal oxides, offering a lower environmental impact due to their durability and recyclability compared to ceramic coatings, which often involve energy-intensive manufacturing processes. Enamel's long lifespan reduces the need for frequent replacement, minimizing resource consumption and waste generation. Ceramic coatings can be more challenging to recycle, whereas enamel products typically have established recycling streams, enhancing sustainability.

Enamel vs Ceramic Infographic

materialdif.com

materialdif.com