Enamel coating provides a smooth, glossy finish that enhances corrosion resistance and is ideal for metal surfaces exposed to moderate wear. Powder coating, applied as a dry powder and cured under heat, offers a thicker, more durable layer that resists chipping, scratching, and fading. Both coatings improve surface protection, but powder coating generally delivers superior durability for heavy-duty applications.

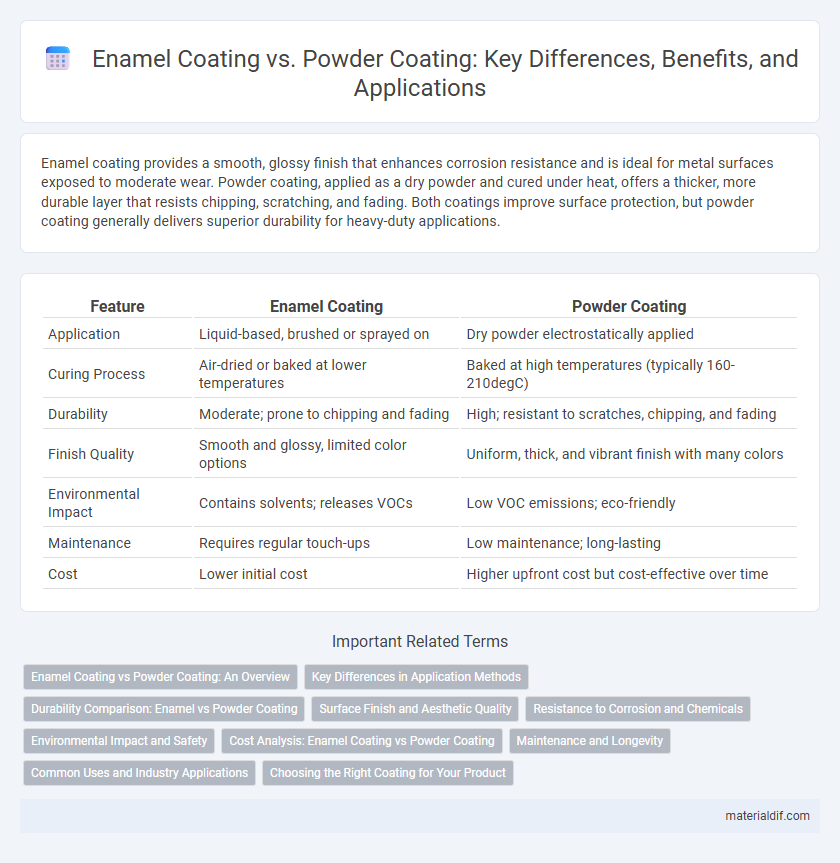

Table of Comparison

| Feature | Enamel Coating | Powder Coating |

|---|---|---|

| Application | Liquid-based, brushed or sprayed on | Dry powder electrostatically applied |

| Curing Process | Air-dried or baked at lower temperatures | Baked at high temperatures (typically 160-210degC) |

| Durability | Moderate; prone to chipping and fading | High; resistant to scratches, chipping, and fading |

| Finish Quality | Smooth and glossy, limited color options | Uniform, thick, and vibrant finish with many colors |

| Environmental Impact | Contains solvents; releases VOCs | Low VOC emissions; eco-friendly |

| Maintenance | Requires regular touch-ups | Low maintenance; long-lasting |

| Cost | Lower initial cost | Higher upfront cost but cost-effective over time |

Enamel Coating vs Powder Coating: An Overview

Enamel coating provides a smooth, glossy finish with excellent resistance to moisture and corrosion, making it ideal for metal surfaces exposed to harsh environments. Powder coating offers a thicker, more durable layer that resists chipping and fading, suitable for heavy-duty applications requiring long-lasting protection. Both coatings enhance surface durability, but enamel is preferred for aesthetic appeal, while powder coating excels in toughness and environmental resistance.

Key Differences in Application Methods

Enamel coating requires a liquid application process commonly involving brushes, spray guns, or dipping, allowing for smooth, glossy finishes that dry through solvent evaporation. Powder coating involves electrostatically applying dry powder, followed by curing under heat to form a durable, uniform layer resistant to chipping and corrosion. Enamel is suited for detailed, delicate surfaces, while powder coating provides thicker, more resilient protection ideal for metal substrates.

Durability Comparison: Enamel vs Powder Coating

Enamel coatings offer a glossy finish with moderate durability, resisting chipping and fading better than traditional paints but less effectively against impact and abrasion compared to powder coatings. Powder coating provides a thicker, more uniform layer that delivers superior toughness, enhanced resistance to corrosion, UV rays, and mechanical wear, making it ideal for outdoor and industrial applications. The choice between enamel and powder coating depends on the required durability level, environmental exposure, and maintenance preferences.

Surface Finish and Aesthetic Quality

Enamel coating provides a smooth, glossy surface finish that enhances aesthetic appeal with vibrant colors and a glass-like sheen. Powder coating offers a thicker, more durable finish with consistent texture and is available in a wide range of matte and textured options, but typically lacks the high gloss of enamel. Both coatings improve surface protection, but enamel excels in delivering superior visual gloss and subtle depth, while powder coating prioritizes robustness and uniform coverage.

Resistance to Corrosion and Chemicals

Enamel coating provides superior resistance to corrosion and chemicals due to its glass-like surface that effectively seals the substrate against moisture and acidic substances. Powder coating, while durable and resistant to chipping, can develop microscopic pores that may allow corrosive agents to penetrate over time. Enamel's dense, smooth finish offers enhanced protection in harsh chemical environments, making it ideal for applications requiring long-term corrosion resistance.

Environmental Impact and Safety

Enamel coating typically involves solvent-based paints that release volatile organic compounds (VOCs), contributing to air pollution and requiring careful handling to avoid hazardous exposure. Powder coating is an environmentally safer option as it emits negligible VOCs and produces minimal waste, with overspray being recyclable and reducing environmental contamination. Both coatings require proper safety measures, though powder coating generally poses lower risks of toxic fumes and hazardous chemical exposure during application.

Cost Analysis: Enamel Coating vs Powder Coating

Enamel coating typically involves lower initial equipment costs and simpler application processes, making it more cost-effective for small-scale or touch-up jobs. Powder coating demands higher upfront investment in equipment and curing ovens but offers superior durability and minimal waste, reducing long-term maintenance and recoat expenses. Evaluating total lifecycle costs reveals powder coating as more economical for large production runs and projects requiring enhanced corrosion resistance.

Maintenance and Longevity

Enamel coating offers a smooth, glossy finish that resists chipping and is relatively easy to maintain through regular cleaning, but it may degrade faster under prolonged UV exposure compared to powder coating. Powder coating provides a thicker, more durable layer that excels in resisting scratches, corrosion, and fading, significantly extending the lifespan of the coated surface with minimal upkeep. Both coatings require proper surface preparation, but powder coating generally demands less frequent maintenance and delivers superior longevity in harsh environments.

Common Uses and Industry Applications

Enamel coating is widely used in automotive parts, kitchen appliances, and decorative items due to its glossy finish and excellent resistance to heat and chemicals. Powder coating is preferred in industrial machinery, outdoor furniture, and architectural frames for its durability, uniform coverage, and environmental friendliness. Both coatings serve essential roles across manufacturing, automotive, construction, and consumer goods industries, with enamel offering aesthetic appeal and powder coating providing superior protection.

Choosing the Right Coating for Your Product

Enamel coating offers a smooth, glossy finish with excellent resistance to heat and chemicals, making it ideal for appliances and automotive parts requiring high durability and aesthetic appeal. Powder coating provides a thicker, more uniform layer that enhances corrosion resistance and impact protection, suitable for outdoor equipment and industrial components exposed to harsh environments. Selecting the right coating depends on the product's usage conditions, desired appearance, and performance requirements to ensure long-lasting protection and visual quality.

Enamel coating vs Powder coating Infographic

materialdif.com

materialdif.com