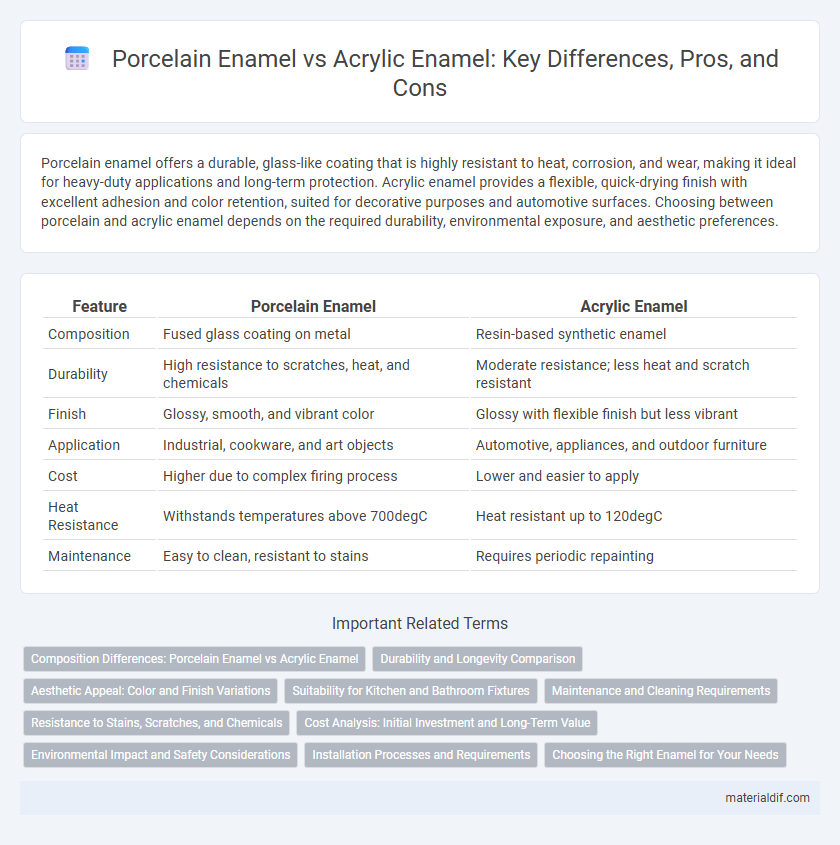

Porcelain enamel offers a durable, glass-like coating that is highly resistant to heat, corrosion, and wear, making it ideal for heavy-duty applications and long-term protection. Acrylic enamel provides a flexible, quick-drying finish with excellent adhesion and color retention, suited for decorative purposes and automotive surfaces. Choosing between porcelain and acrylic enamel depends on the required durability, environmental exposure, and aesthetic preferences.

Table of Comparison

| Feature | Porcelain Enamel | Acrylic Enamel |

|---|---|---|

| Composition | Fused glass coating on metal | Resin-based synthetic enamel |

| Durability | High resistance to scratches, heat, and chemicals | Moderate resistance; less heat and scratch resistant |

| Finish | Glossy, smooth, and vibrant color | Glossy with flexible finish but less vibrant |

| Application | Industrial, cookware, and art objects | Automotive, appliances, and outdoor furniture |

| Cost | Higher due to complex firing process | Lower and easier to apply |

| Heat Resistance | Withstands temperatures above 700degC | Heat resistant up to 120degC |

| Maintenance | Easy to clean, resistant to stains | Requires periodic repainting |

Composition Differences: Porcelain Enamel vs Acrylic Enamel

Porcelain enamel consists primarily of powdered glass fused to a metal substrate at high temperatures, creating a hard, durable, and chemically resistant coating. Acrylic enamel is composed of synthetic resins and pigments, offering flexibility and quicker drying times but with less hardness and heat resistance. The key composition difference lies in porcelain enamel's inorganic glass matrix versus acrylic enamel's organic polymer base.

Durability and Longevity Comparison

Porcelain enamel offers superior durability and longevity due to its glass-like surface fused at high temperatures, providing excellent resistance to scratches, chemicals, and extreme weather conditions. Acrylic enamel, while more flexible and easier to apply, tends to chip and fade faster under prolonged exposure to UV rays and harsh environments. The long-lasting nature of porcelain enamel makes it ideal for applications requiring sustained protection and aesthetic retention over time.

Aesthetic Appeal: Color and Finish Variations

Porcelain enamel offers superior aesthetic appeal with its vibrant color retention and glossy, smooth finish that resists fading and chipping over time. Acrylic enamel provides a wider range of colors and finishes, including matte and satin options, but tends to lack the long-term durability of porcelain coatings. The choice between porcelain and acrylic enamel significantly impacts the visual longevity and surface texture of coated surfaces.

Suitability for Kitchen and Bathroom Fixtures

Porcelain enamel offers superior durability and resistance to high temperatures, making it highly suitable for kitchen and bathroom fixtures exposed to moisture and heat. Acrylic enamel provides good aesthetic flexibility and faster curing times but tends to be less resistant to scratching and chemical damage in wet environments. The non-porous surface of porcelain enamel ensures easier cleaning and better long-term hygiene in both kitchens and bathrooms.

Maintenance and Cleaning Requirements

Porcelain enamel offers superior durability and resistance to stains, making it easier to maintain with simple non-abrasive cleaners and minimal effort over time. Acrylic enamel requires more frequent cleaning and touch-ups due to its susceptibility to scratches and chemical damage, demanding gentler cleaning agents and routine maintenance to preserve its finish. Choosing porcelain enamel reduces long-term upkeep costs and effort compared to acrylic enamel in high-traffic or exposed environments.

Resistance to Stains, Scratches, and Chemicals

Porcelain enamel offers superior resistance to stains, scratches, and chemicals due to its glass-like, non-porous surface that resists discoloration and abrasion over time. Acrylic enamel, while more flexible and easier to apply, is more prone to scratching and chemical damage, making it less durable in harsh environments. This makes porcelain enamel the preferred choice for applications requiring long-term durability and resistance to harsh cleaning agents.

Cost Analysis: Initial Investment and Long-Term Value

Porcelain enamel commands a higher initial investment due to its complex application process and durability, but offers superior long-term value through exceptional resistance to scratching, fading, and corrosion. Acrylic enamel, while more affordable upfront, typically requires more frequent maintenance and repainting, leading to increased lifecycle costs. Evaluating total cost of ownership reveals porcelain enamel as a cost-effective choice for projects demanding longevity and minimal upkeep.

Environmental Impact and Safety Considerations

Porcelain enamel, composed of powdered glass fused to metal at high temperatures, offers superior chemical resistance and durability, reducing the need for frequent recoating and minimizing waste generation. Acrylic enamel, a solvent-based paint, releases volatile organic compounds (VOCs) during application and curing, contributing to air pollution and posing inhalation hazards, whereas porcelain enamel emits negligible VOCs. The inert, non-toxic nature of porcelain enamel makes it safer for the environment and human health, contrasting with the potential toxicity and flammability risks associated with acrylic enamel formulations.

Installation Processes and Requirements

Porcelain enamel requires a high-temperature kiln firing process, typically between 1,400degF and 1,600degF, necessitating specialized equipment and surface preparation such as cleaning, degreasing, and applying a ground coat to ensure proper adhesion and durability. Acrylic enamel, on the other hand, cures at room temperature or low heat, allowing for easier application using spray guns or brushes without the need for extensive surface treatment or high-temperature baking. The installation of porcelain enamel is more labor-intensive and costly but results in a harder, more durable finish compared to the faster, more flexible, and less expensive application process of acrylic enamel.

Choosing the Right Enamel for Your Needs

Porcelain enamel offers superior durability, resistance to chemicals, and a glossy, glass-like finish ideal for cookware, appliances, and architectural applications. Acrylic enamel provides faster drying times, flexibility, and ease of application, making it suitable for automotive finishes, outdoor furniture, and decorative projects. Choosing the right enamel depends on factors like exposure to heat, weather conditions, surface material, and desired aesthetic longevity.

porcelain enamel vs acrylic enamel Infographic

materialdif.com

materialdif.com