Enamel lining and epoxy lining both offer protective coatings but differ significantly in durability and application. Enamel lining provides a hard, glossy surface resistant to high temperatures and chemical corrosion, ideal for industrial equipment. Epoxy lining, known for its flexibility and strong adhesive properties, excels in environments requiring resistance to abrasion and moisture.

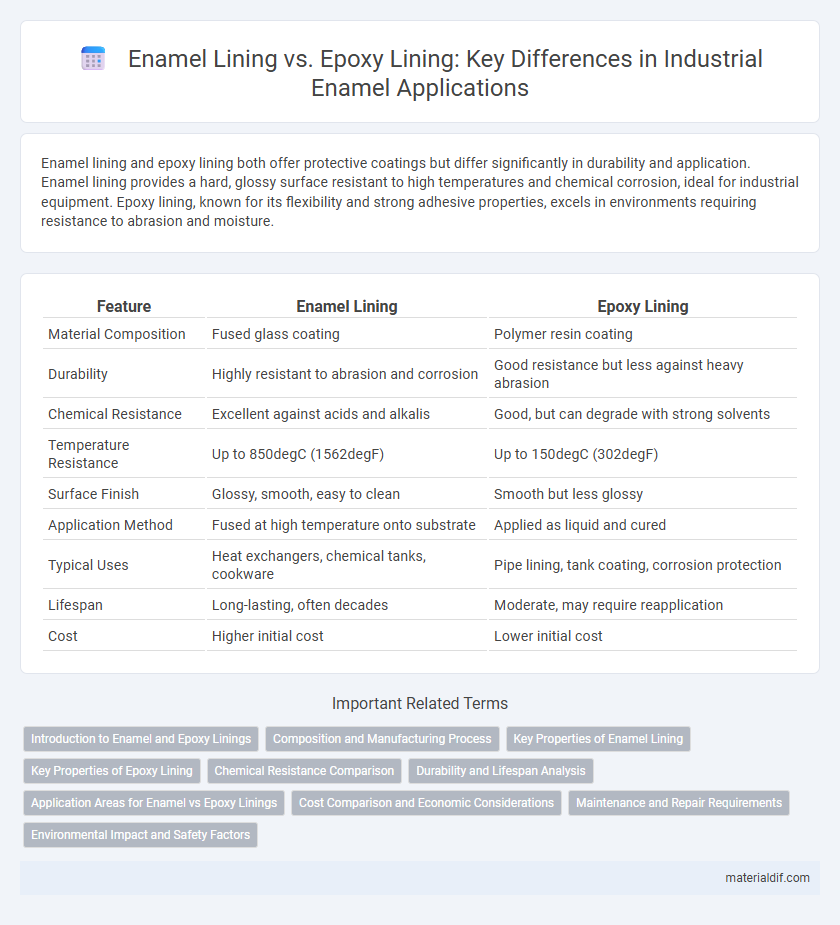

Table of Comparison

| Feature | Enamel Lining | Epoxy Lining |

|---|---|---|

| Material Composition | Fused glass coating | Polymer resin coating |

| Durability | Highly resistant to abrasion and corrosion | Good resistance but less against heavy abrasion |

| Chemical Resistance | Excellent against acids and alkalis | Good, but can degrade with strong solvents |

| Temperature Resistance | Up to 850degC (1562degF) | Up to 150degC (302degF) |

| Surface Finish | Glossy, smooth, easy to clean | Smooth but less glossy |

| Application Method | Fused at high temperature onto substrate | Applied as liquid and cured |

| Typical Uses | Heat exchangers, chemical tanks, cookware | Pipe lining, tank coating, corrosion protection |

| Lifespan | Long-lasting, often decades | Moderate, may require reapplication |

| Cost | Higher initial cost | Lower initial cost |

Introduction to Enamel and Epoxy Linings

Enamel lining consists of a durable glass-based coating fused to metal surfaces at high temperatures, offering excellent resistance to corrosion, heat, and chemical attack. Epoxy lining is a polymer-based coating applied to metal substrates, providing superior chemical resistance and flexibility, often used in environments with aggressive substances. Both linings serve as protective barriers in industrial applications, with enamel favored for its hardness and epoxy for its abrasion resistance and ease of application.

Composition and Manufacturing Process

Enamel lining is composed of powdered glass fused onto a metal surface at high temperatures, creating a durable, non-porous coating resistant to corrosion and chemical attack. The manufacturing process involves heating the metal substrate to around 750-850degC, allowing the glass particles to melt and form a strong, glassy bond with the metal. In contrast, epoxy lining is made from organic polymer resins that cure at lower temperatures through chemical reactions, resulting in a flexible and impact-resistant coating ideal for less aggressive environments.

Key Properties of Enamel Lining

Enamel lining offers superior corrosion resistance and exceptional hardness, making it ideal for protecting metal surfaces in harsh industrial environments. Its smooth, non-porous finish prevents chemical adherence and facilitates easy cleaning, enhancing durability compared to epoxy linings. Unlike epoxy, enamel provides excellent thermal stability and resistance to UV degradation, ensuring long-term performance and aesthetic retention.

Key Properties of Epoxy Lining

Epoxy lining is highly valued for its exceptional chemical resistance, providing superior protection against acids, alkalis, and solvents compared to enamel lining. Its strong adhesion to various substrates and flexibility make it ideal for applications requiring durability and resistance to cracking or peeling. Furthermore, epoxy lining offers excellent corrosion resistance and low permeability, enhancing the longevity of tanks, pipes, and industrial equipment.

Chemical Resistance Comparison

Enamel lining offers superior chemical resistance against strong acids and oxidizing agents due to its glassy, inert surface, making it ideal for environments with aggressive chemicals. Epoxy lining provides good chemical resistance but is more susceptible to degradation from alkaline substances and certain solvents over time. Selecting the appropriate lining requires careful evaluation of chemical exposure, temperature conditions, and mechanical stress to ensure optimal durability and performance.

Durability and Lifespan Analysis

Enamel lining offers superior resistance to high temperatures and chemical corrosion, resulting in exceptional durability for industrial applications requiring long-term protection. Epoxy lining provides excellent adhesion and flexibility but generally has a shorter lifespan, especially under extreme thermal or abrasive conditions. The choice between enamel and epoxy lining depends on the operational environment, with enamel favored for extended durability and lifespan under harsh conditions.

Application Areas for Enamel vs Epoxy Linings

Enamel linings are commonly applied in high-temperature environments such as chemical reactors, boiler tubes, and food processing equipment due to their excellent resistance to heat and corrosion. Epoxy linings are preferred in water treatment systems, pipelines, and storage tanks where chemical resistance and flexibility to withstand mechanical stress are critical. Both enamel and epoxy coatings protect substrates from corrosion, but enamel excels in thermal stability while epoxy is favored for chemical resistance in wet conditions.

Cost Comparison and Economic Considerations

Enamel lining typically involves higher initial costs due to the labor-intensive application process and material expenses, but offers superior durability and resistance to chemical corrosion, potentially reducing long-term maintenance costs compared to epoxy lining. Epoxy lining generally has lower upfront costs and faster curing times, making it economically favorable for projects with tight budgets or shorter service life requirements. Considering total lifecycle expenses, enamel lining proves more cost-effective in environments demanding high performance and extended durability, while epoxy lining suits less demanding applications with limited financial resources.

Maintenance and Repair Requirements

Enamel lining offers superior resistance to chemical corrosion and abrasion, resulting in lower maintenance frequency compared to epoxy lining, which can be more prone to wear and requires frequent touch-ups. Repairing enamel lining often involves specialized techniques such as flame spray or furnace treatments to restore its durability, whereas epoxy repairs are simpler but may compromise the coating's integrity over time. Maintenance for enamel lining typically ensures longer service life in harsh industrial environments, reducing overall downtime and operational costs.

Environmental Impact and Safety Factors

Enamel lining offers a durable, non-toxic barrier resistant to corrosion and chemical leaching, minimizing environmental contamination and reducing hazardous waste compared to epoxy lining. Epoxy lining may release volatile organic compounds (VOCs) during application and degradation, posing health risks and requiring careful handling and disposal to prevent environmental harm. Enamel's inorganic composition ensures longer service life with fewer reapplications, promoting sustainability and enhanced workplace safety over epoxy alternatives.

Enamel Lining vs Epoxy Lining Infographic

materialdif.com

materialdif.com