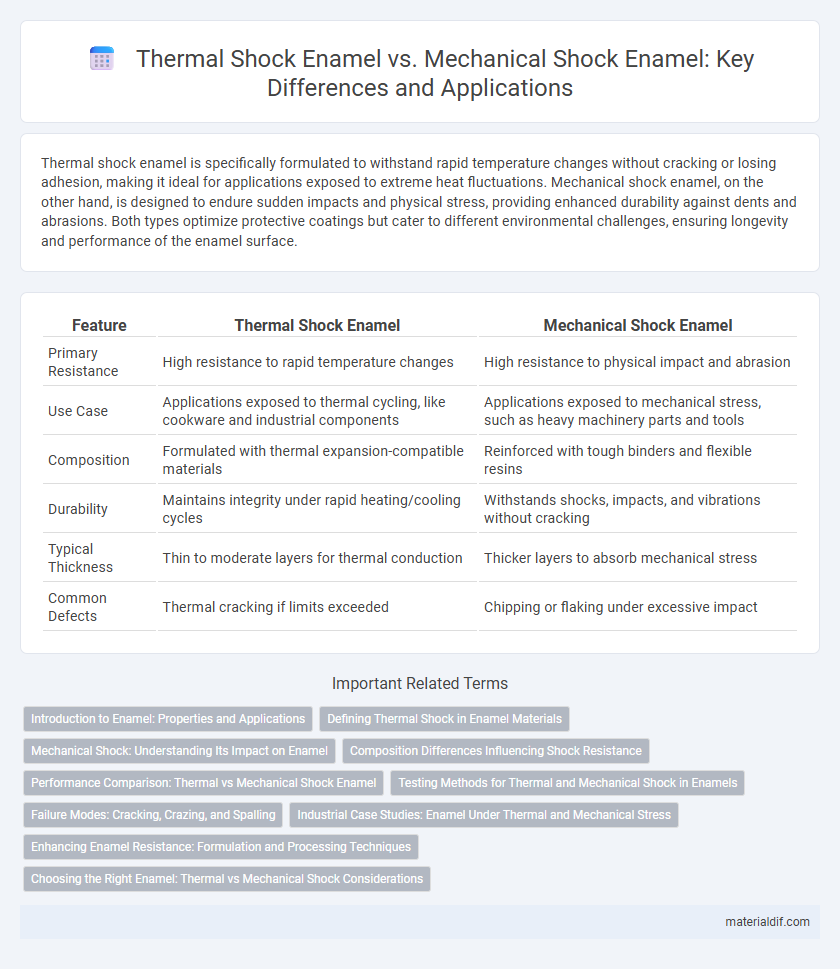

Thermal shock enamel is specifically formulated to withstand rapid temperature changes without cracking or losing adhesion, making it ideal for applications exposed to extreme heat fluctuations. Mechanical shock enamel, on the other hand, is designed to endure sudden impacts and physical stress, providing enhanced durability against dents and abrasions. Both types optimize protective coatings but cater to different environmental challenges, ensuring longevity and performance of the enamel surface.

Table of Comparison

| Feature | Thermal Shock Enamel | Mechanical Shock Enamel |

|---|---|---|

| Primary Resistance | High resistance to rapid temperature changes | High resistance to physical impact and abrasion |

| Use Case | Applications exposed to thermal cycling, like cookware and industrial components | Applications exposed to mechanical stress, such as heavy machinery parts and tools |

| Composition | Formulated with thermal expansion-compatible materials | Reinforced with tough binders and flexible resins |

| Durability | Maintains integrity under rapid heating/cooling cycles | Withstands shocks, impacts, and vibrations without cracking |

| Typical Thickness | Thin to moderate layers for thermal conduction | Thicker layers to absorb mechanical stress |

| Common Defects | Thermal cracking if limits exceeded | Chipping or flaking under excessive impact |

Introduction to Enamel: Properties and Applications

Thermal shock enamel resists rapid temperature changes by maintaining structural integrity through its low thermal expansion coefficient, making it ideal for cookware and industrial components exposed to fluctuating heat. Mechanical shock enamel offers high impact resistance and durability, suitable for protective coatings on machinery and automotive parts subject to physical stress. Both types of enamel enhance surface hardness, corrosion resistance, and aesthetic appearance in diverse applications.

Defining Thermal Shock in Enamel Materials

Thermal shock in enamel materials refers to the stress and potential cracking caused by rapid temperature changes that induce uneven expansion or contraction within the enamel layer. This phenomenon differs from mechanical shock enamel, which pertains to physical impacts or sudden mechanical forces causing surface damage or fractures. Understanding thermal shock resistance is critical for enamel coatings used in applications exposed to fluctuating heat, ensuring durability and longevity in environments like cookware, electrical insulators, and automotive parts.

Mechanical Shock: Understanding Its Impact on Enamel

Mechanical shock enamel resists sudden physical impacts by maintaining structural integrity under rapid force or vibration, critical in applications like cookware and industrial equipment. Its durability depends on the enamel's composition, thickness, and bonding strength to the substrate, which absorb and dissipate shock energy to prevent cracking or chipping. Understanding mechanical shock impact allows manufacturers to improve enamel performance, ensuring longevity and safety in high-stress environments.

Composition Differences Influencing Shock Resistance

Thermal shock enamel typically contains high amounts of silica and alumina, enhancing its ability to withstand rapid temperature changes without cracking. Mechanical shock enamel incorporates increased levels of flexible oxides such as boron oxide and varying glassy phases to absorb impact stresses. These compositional differences directly influence the enamel's microstructure, optimizing resistance to either thermal expansion mismatch or mechanical impact forces.

Performance Comparison: Thermal vs Mechanical Shock Enamel

Thermal shock enamel exhibits superior resistance to rapid temperature changes, maintaining structural integrity without cracking or delaminating, making it ideal for high-heat applications. Mechanical shock enamel, on the other hand, is formulated to absorb and withstand impact forces, providing enhanced durability against physical stress and abrasion. Performance comparison shows thermal shock enamel excels in thermal stability, while mechanical shock enamel offers better resilience to mechanical impacts, guiding material selection based on specific operational demands.

Testing Methods for Thermal and Mechanical Shock in Enamels

Testing methods for thermal shock enamel involve rapid temperature cycling between extreme heat and cold to assess resistance to cracking or crazing under sudden thermal changes. Mechanical shock enamel testing uses impact devices or drop tests to evaluate the enamel's ability to withstand sudden physical forces without chipping or delamination. Both testing procedures are critical for ensuring enamel durability in applications requiring resistance to abrupt environmental or mechanical stresses.

Failure Modes: Cracking, Crazing, and Spalling

Thermal shock enamel fails primarily due to rapid temperature changes causing cracking and crazing from differential expansion rates between enamel and substrate. Mechanical shock enamel experiences spalling and cracking as a result of sudden impact or mechanical stress exceeding enamel's tensile strength. Both types of enamel are susceptible to these failure modes but differ in their stress origins--thermal gradients versus physical force.

Industrial Case Studies: Enamel Under Thermal and Mechanical Stress

Industrial case studies reveal that thermal shock enamel withstands rapid temperature changes by maintaining adhesion and preventing cracking in heat exchangers and automotive components. Mechanical shock enamel demonstrates superior resistance to impact and abrasion, essential for protective coatings in machinery exposed to vibration and sudden forces. Comparative analyses highlight the importance of selecting enamel formulations tailored to specific industrial stressors for optimized durability and performance.

Enhancing Enamel Resistance: Formulation and Processing Techniques

Enhancing enamel resistance involves optimizing formulation and processing techniques tailored to thermal and mechanical shock conditions. Thermal shock enamel requires precise control of coefficient of thermal expansion and firing temperature to prevent cracking under rapid temperature changes. Mechanical shock enamel benefits from increased flexibility and adhesion properties through additives and substrate surface treatments to withstand impact and abrasion without chipping.

Choosing the Right Enamel: Thermal vs Mechanical Shock Considerations

Thermal shock enamel offers superior resistance to rapid temperature changes, making it ideal for applications involving extreme heat variations like cookware and industrial equipment. Mechanical shock enamel provides enhanced durability against physical impacts and abrasion, suited for objects exposed to frequent handling or mechanical stress such as jewelry and automotive parts. Selecting the right enamel depends on the specific environmental conditions and performance requirements, balancing thermal resilience against impact toughness.

Thermal shock enamel vs Mechanical shock enamel Infographic

materialdif.com

materialdif.com