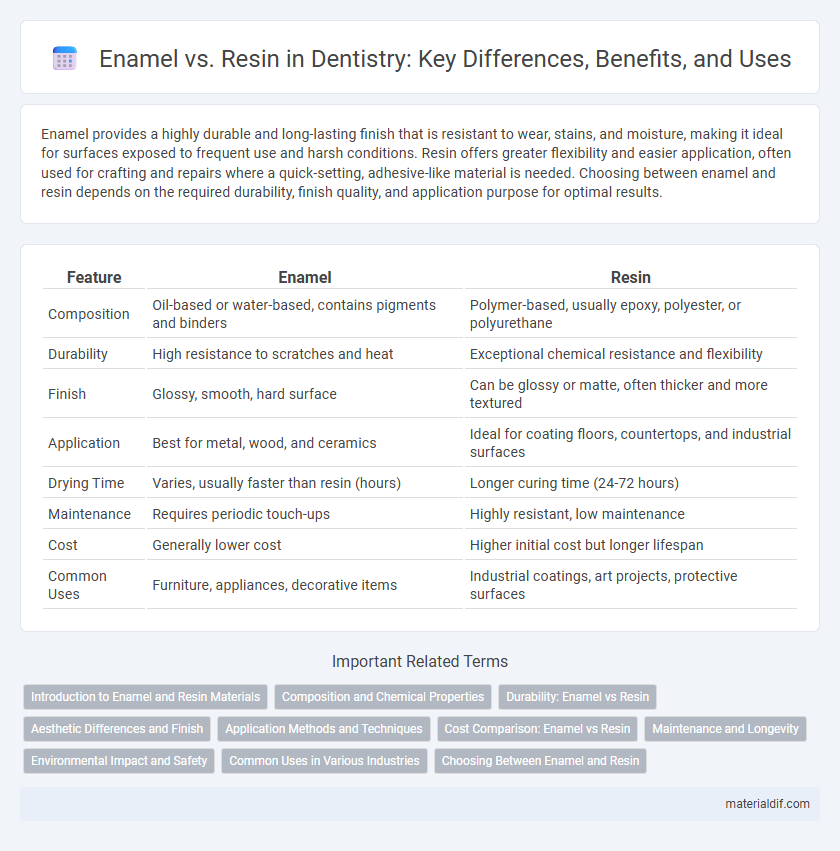

Enamel provides a highly durable and long-lasting finish that is resistant to wear, stains, and moisture, making it ideal for surfaces exposed to frequent use and harsh conditions. Resin offers greater flexibility and easier application, often used for crafting and repairs where a quick-setting, adhesive-like material is needed. Choosing between enamel and resin depends on the required durability, finish quality, and application purpose for optimal results.

Table of Comparison

| Feature | Enamel | Resin |

|---|---|---|

| Composition | Oil-based or water-based, contains pigments and binders | Polymer-based, usually epoxy, polyester, or polyurethane |

| Durability | High resistance to scratches and heat | Exceptional chemical resistance and flexibility |

| Finish | Glossy, smooth, hard surface | Can be glossy or matte, often thicker and more textured |

| Application | Best for metal, wood, and ceramics | Ideal for coating floors, countertops, and industrial surfaces |

| Drying Time | Varies, usually faster than resin (hours) | Longer curing time (24-72 hours) |

| Maintenance | Requires periodic touch-ups | Highly resistant, low maintenance |

| Cost | Generally lower cost | Higher initial cost but longer lifespan |

| Common Uses | Furniture, appliances, decorative items | Industrial coatings, art projects, protective surfaces |

Introduction to Enamel and Resin Materials

Enamel is a durable, glass-like coating fused to metal or ceramics through high-temperature firing, valued for its resistance to wear, corrosion, and aesthetic appeal in jewelry and art. Resin is a versatile synthetic polymer, often used as a lightweight, flexible alternative to enamel, offering ease of application and a wide range of colors but less heat resistance. Both materials are popular in decorative arts and manufacturing, with enamel preferred for its longevity and resin favored for its adaptability and cost-effectiveness.

Composition and Chemical Properties

Enamel is a highly mineralized, inorganic substance primarily composed of hydroxyapatite crystals, giving it exceptional hardness and resistance to chemical erosion. Resin, in contrast, consists of synthetic organic polymers like bis-GMA and UDMA, which offer greater flexibility but lower hardness compared to enamel. The chemical stability of enamel is due to its crystalline structure, whereas resin's chemical properties allow for easier manipulation and adhesion but make it more susceptible to degradation over time.

Durability: Enamel vs Resin

Enamel offers superior durability with its hard, glass-like coating that resists scratches, stains, and heat more effectively than resin. Resin, while flexible and impact-resistant, tends to wear down faster and can discolor over time when exposed to UV light and chemicals. For applications requiring long-lasting surface protection, enamel is generally the preferred choice due to its robustness and longevity.

Aesthetic Differences and Finish

Enamel offers a glossy, durable finish that closely mimics the natural shine of tooth surfaces, providing superior aesthetic appeal in dental restorations. Resin, while versatile and easier to manipulate, typically results in a softer, less lustrous finish that may yellow over time under exposure to UV light. The enamel's high translucency and resistance to staining create a long-lasting, natural appearance, distinguishing it from resin's comparatively matte and less resilient surface.

Application Methods and Techniques

Enamel is typically applied using spray guns or brushes, allowing for a smooth, durable finish ideal for metal and ceramic surfaces, while resin often requires careful mixing and curing processes, including the use of molds or direct application with spatulas or syringes for precision. Enamel application benefits from high-temperature firing to achieve hardness and gloss, whereas resin cures at room temperature or under UV light, providing flexibility in crafting applications. The choice of technique directly impacts adhesion, durability, and aesthetic qualities, making enamel preferable for long-lasting coatings and resin suitable for detailed, customizable designs.

Cost Comparison: Enamel vs Resin

Enamel paint generally costs more than resin-based coatings due to its higher-quality pigments and durability, making it a preferred choice for long-lasting finishes. Resin coatings are typically less expensive but may require more frequent maintenance or recoating over time, affecting overall cost efficiency. When comparing cost-effectiveness, enamel offers better value in applications demanding toughness, while resin suits budget-conscious projects with lower exposure to wear.

Maintenance and Longevity

Enamel provides superior durability and requires less maintenance compared to resin, which is more prone to chipping and discoloration over time. Enamel's hard, glass-like surface resists wear and retains its shine longer, making it ideal for heavy-use applications and long-term projects. Resin surfaces often need regular sealing and repairs to maintain their appearance and structural integrity.

Environmental Impact and Safety

Enamel coatings, typically composed of durable, chemically resistant materials like alkyd or epoxy, often contain volatile organic compounds (VOCs) that can contribute to environmental pollution and pose health risks during application. Resin-based finishes, especially those using bio-based or waterborne resins, generally offer a lower environmental footprint due to reduced VOC emissions and increased biodegradability. Safety profiles favor modern resin formulations that minimize toxic exposure and improve indoor air quality, whereas traditional enamel paints require careful handling and ventilation to mitigate potential hazards.

Common Uses in Various Industries

Enamel coatings are widely used in automotive, appliance, and marine industries for their durability and glossy finish, providing corrosion resistance and aesthetic appeal. Resin-based coatings find extensive application in construction, electronics, and packaging industries due to their flexibility, chemical resistance, and insulating properties. Both materials serve vital roles, with enamel favored for hard, protective surfaces and resin preferred for versatile, lightweight products.

Choosing Between Enamel and Resin

Choosing between enamel and resin depends on the project's requirements for durability and finish. Enamel provides a hard, glossy finish resistant to scratches and chemicals, ideal for outdoor or heavy-use applications. Resin offers flexibility and a smooth, even coat, making it suitable for intricate details and indoor projects where a softer finish is preferred.

Enamel vs Resin Infographic

materialdif.com

materialdif.com