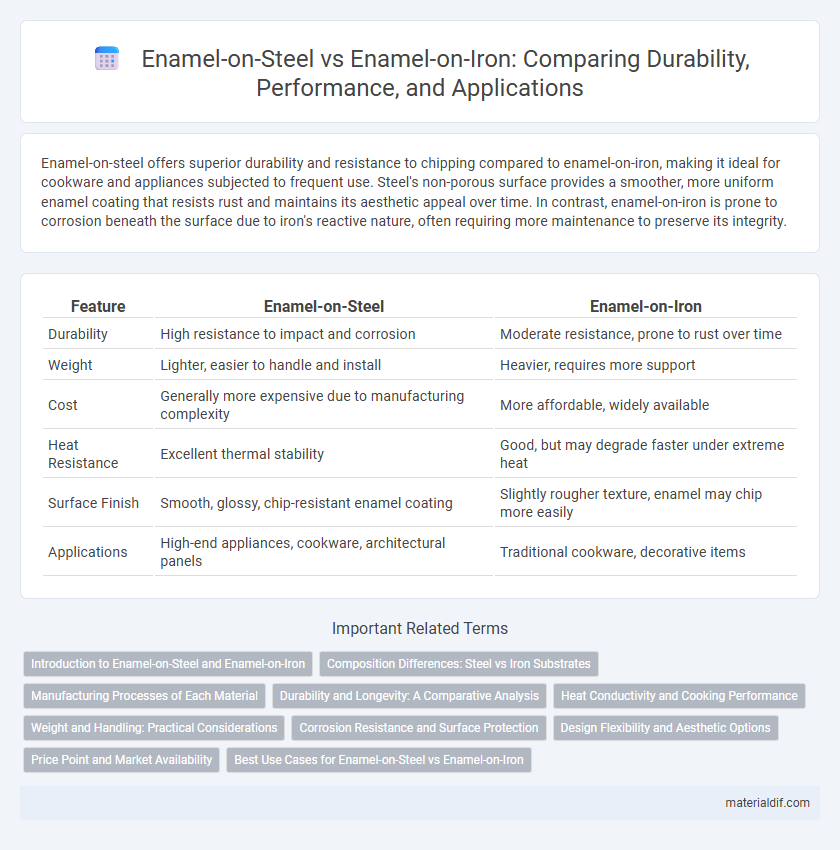

Enamel-on-steel offers superior durability and resistance to chipping compared to enamel-on-iron, making it ideal for cookware and appliances subjected to frequent use. Steel's non-porous surface provides a smoother, more uniform enamel coating that resists rust and maintains its aesthetic appeal over time. In contrast, enamel-on-iron is prone to corrosion beneath the surface due to iron's reactive nature, often requiring more maintenance to preserve its integrity.

Table of Comparison

| Feature | Enamel-on-Steel | Enamel-on-Iron |

|---|---|---|

| Durability | High resistance to impact and corrosion | Moderate resistance, prone to rust over time |

| Weight | Lighter, easier to handle and install | Heavier, requires more support |

| Cost | Generally more expensive due to manufacturing complexity | More affordable, widely available |

| Heat Resistance | Excellent thermal stability | Good, but may degrade faster under extreme heat |

| Surface Finish | Smooth, glossy, chip-resistant enamel coating | Slightly rougher texture, enamel may chip more easily |

| Applications | High-end appliances, cookware, architectural panels | Traditional cookware, decorative items |

Introduction to Enamel-on-Steel and Enamel-on-Iron

Enamel-on-steel combines a durable steel base with a smooth, glassy enamel coating, providing excellent resistance to corrosion and heat, making it ideal for cookware and appliances. Enamel-on-iron features a cast iron core coated with enamel, offering superior heat retention and even distribution, favored in high-quality cookware. Both materials enhance the longevity and aesthetic appeal of products, but enamel-on-steel is lighter and more impact-resistant, while enamel-on-iron excels in heat performance.

Composition Differences: Steel vs Iron Substrates

Enamel-on-steel combines a flexible steel substrate with a vitreous enamel coating, offering enhanced durability and resistance to chipping compared to enamel-on-iron, which uses a more brittle iron base prone to corrosion. Steel substrates contain a higher carbon content and are alloyed with elements like manganese and chromium for improved strength and corrosion resistance under the enamel layer. Iron substrates, primarily composed of cast iron or wrought iron, have a higher carbon content but lack alloying elements, making enamel-on-iron more susceptible to rust and structural weaknesses over time.

Manufacturing Processes of Each Material

Enamel-on-steel involves fusing powdered glass to a steel base at approximately 800-900degC, benefiting from steel's uniform surface and higher tensile strength for a smooth, durable finish. Enamel-on-iron requires similar high-temperature firing but must address cast iron's porous and uneven surface through pre-treatment processes like sandblasting or acid washing to ensure proper enamel adhesion. Both methods use precise temperature control and surface preparation, but steel substrates generally allow for more consistent enamel layer thickness and reduced cracking risk during cooling.

Durability and Longevity: A Comparative Analysis

Enamel-on-steel offers superior durability and longevity compared to enamel-on-iron due to steel's higher tensile strength and resistance to warping under thermal stress. The enamel coating on steel forms a more resilient bond, reducing the risk of chipping and corrosion over time, which extends the lifespan of cookware and appliances. In contrast, enamel-on-iron is more prone to cracking and rust, necessitating more frequent maintenance and replacements.

Heat Conductivity and Cooking Performance

Enamel-on-steel cookware offers superior heat conductivity due to steel's ability to distribute heat evenly and maintain stable cooking temperatures, enhancing cooking performance by reducing hot spots. In contrast, enamel-on-iron cookware retains heat longer because of cast iron's density but has slower heat responsiveness, which can lead to uneven heating during temperature changes. Choosing enamel-on-steel results in faster heat adjustments and consistent cooking, while enamel-on-iron excels in heat retention for slow-cooked dishes.

Weight and Handling: Practical Considerations

Enamel-on-steel cookware offers a lighter weight compared to enamel-on-iron, making it easier to handle and maneuver during cooking. Steel's reduced weight improves comfort and reduces strain, especially for larger pans and pots, enhancing kitchen efficiency. While enamel-on-iron provides superior heat retention, enamel-on-steel's advantage in weight makes it a practical choice for everyday use and frequent handling.

Corrosion Resistance and Surface Protection

Enamel-on-steel offers superior corrosion resistance due to the steel's alloy composition, which enhances durability against rust and environmental factors compared to enamel-on-iron. The surface protection of enamel-on-steel is more robust, benefiting from the steel substrate's higher tensile strength and better bonding with enamel coatings, resulting in fewer chips and cracks. Enamel-on-iron, while cost-effective, is more prone to corrosion and surface wear because iron oxidizes faster and forms weaker adhesion with the enamel layer.

Design Flexibility and Aesthetic Options

Enamel-on-steel offers greater design flexibility and a wider range of aesthetic options compared to enamel-on-iron due to steel's smoother surface, allowing for more intricate and detailed enamel patterns. The enhanced durability of steel substrates supports vibrant, long-lasting colors and finishes that maintain aesthetic appeal over time. In contrast, enamel-on-iron tends to have a rougher texture, limiting the complexity and finesse of decorative enamel applications.

Price Point and Market Availability

Enamel-on-steel cookware generally offers a lower price point and wider market availability compared to enamel-on-iron due to steel's lighter weight and cheaper production costs. Enamel-on-iron, often favored for its superior heat retention and durability, commands a higher price and is less commonly stocked across retailers. Market trends indicate enamel-on-steel dominates entry-level to mid-range segments, while enamel-on-iron targets premium consumers and specialty stores.

Best Use Cases for Enamel-on-Steel vs Enamel-on-Iron

Enamel-on-steel is best suited for cookware and appliances that require lightweight durability and resistance to corrosion, making it ideal for kitchenware like pots, pans, and refrigerators. Enamel-on-iron offers superior heat retention and even heating, making it optimal for cast iron cookware such as Dutch ovens and skillets used in slow cooking or high-temperature applications. Choosing enamel-on-steel ensures easier handling and resistance to rust, while enamel-on-iron excels in thermal performance and durability under intense cooking conditions.

Enamel-on-Steel vs Enamel-on-Iron Infographic

materialdif.com

materialdif.com