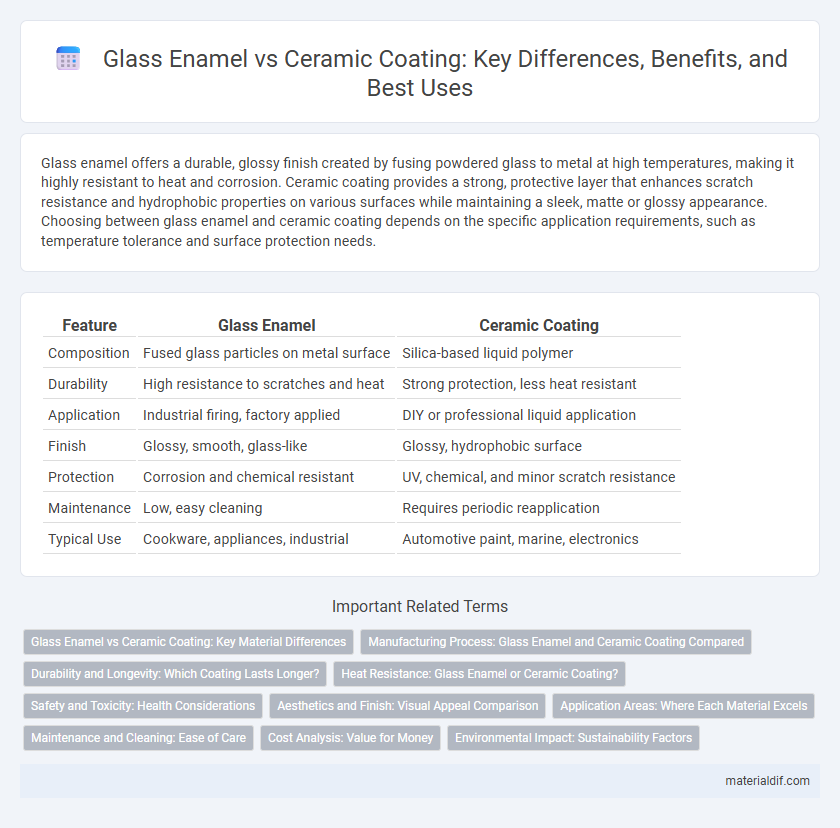

Glass enamel offers a durable, glossy finish created by fusing powdered glass to metal at high temperatures, making it highly resistant to heat and corrosion. Ceramic coating provides a strong, protective layer that enhances scratch resistance and hydrophobic properties on various surfaces while maintaining a sleek, matte or glossy appearance. Choosing between glass enamel and ceramic coating depends on the specific application requirements, such as temperature tolerance and surface protection needs.

Table of Comparison

| Feature | Glass Enamel | Ceramic Coating |

|---|---|---|

| Composition | Fused glass particles on metal surface | Silica-based liquid polymer |

| Durability | High resistance to scratches and heat | Strong protection, less heat resistant |

| Application | Industrial firing, factory applied | DIY or professional liquid application |

| Finish | Glossy, smooth, glass-like | Glossy, hydrophobic surface |

| Protection | Corrosion and chemical resistant | UV, chemical, and minor scratch resistance |

| Maintenance | Low, easy cleaning | Requires periodic reapplication |

| Typical Use | Cookware, appliances, industrial | Automotive paint, marine, electronics |

Glass Enamel vs Ceramic Coating: Key Material Differences

Glass enamel consists of powdered glass fused onto a substrate through high-temperature firing, creating a durable, glossy, and chemically resistant surface. Ceramic coating is typically a liquid polymer applied and cured at lower temperatures, forming a protective layer that offers excellent heat resistance and hydrophobic properties but with less thickness and impact resistance compared to glass enamel. The key differences lie in glass enamel's rigid, fused glass layer versus ceramic coating's flexible, polymer-based film, influencing applications in cookware, automotive finishes, and industrial equipment.

Manufacturing Process: Glass Enamel and Ceramic Coating Compared

Glass enamel manufacturing involves fusing powdered glass onto a metal substrate through high-temperature firing, typically between 750degC and 850degC, creating a durable, vitreous coating. Ceramic coating production relies on chemical vapor deposition or sol-gel processes, forming a thin, nano-structured ceramic layer at lower temperatures, around 200degC to 400degC. The firing process in glass enameling results in a thick, glass-like surface, whereas ceramic coatings produce a thinner, harder layer with enhanced heat and chemical resistance.

Durability and Longevity: Which Coating Lasts Longer?

Glass enamel exhibits superior durability compared to ceramic coating due to its fusion process with metal at high temperatures, creating a hard, non-porous surface resistant to scratches and chemical corrosion. Ceramic coatings offer excellent heat resistance and hydrophobic properties but tend to degrade faster under intense abrasion and UV exposure. Consequently, glass enamel typically lasts longer, making it ideal for applications requiring extended lifespan and robust protection.

Heat Resistance: Glass Enamel or Ceramic Coating?

Glass enamel offers superior heat resistance, typically withstanding temperatures up to 1,200degC (2,192degF), making it ideal for high-heat applications such as cookware and industrial equipment. Ceramic coatings also provide strong heat resistance, usually around 800degC to 1,000degC (1,472degF to 1,832degF), but they are less durable under rapid temperature changes compared to glass enamel. The thermal stability of glass enamel ensures long-lasting performance and resistance to cracking under intense heat stress.

Safety and Toxicity: Health Considerations

Glass enamel is non-toxic and highly resistant to leaching, making it safe for food contact and reducing health risks associated with chemical exposure. Ceramic coatings often contain nanomaterials that, if improperly applied or damaged, may pose inhalation hazards or release toxic particles. Choosing glass enamel ensures minimal toxicity and better long-term safety for cookware and surface protection.

Aesthetics and Finish: Visual Appeal Comparison

Glass enamel offers a high-gloss, vibrant finish with exceptional clarity and a smooth, reflective surface that enhances color depth and brilliance. Ceramic coatings provide a subtly textured, matte to semi-gloss appearance, delivering a contemporary and sophisticated look with excellent durability. While glass enamel excels in bright, eye-catching aesthetics, ceramic coatings are favored for their modern, understated elegance and resistance to surface wear.

Application Areas: Where Each Material Excels

Glass enamel excels in applications requiring durable, heat-resistant surfaces such as kitchen appliances, cookware, and architectural panels due to its ability to withstand high temperatures and chemical exposure. Ceramic coatings are preferred for automotive parts, industrial machinery, and electronics where lightweight, wear resistance, and thermal barrier properties are critical. Both materials offer protective and aesthetic benefits, but glass enamel is dominant in high-temperature environments while ceramic coatings specialize in advanced, high-performance protective layers.

Maintenance and Cleaning: Ease of Care

Glass enamel surfaces are highly resistant to stains and scratches, making maintenance straightforward with just mild detergents and soft sponges. Ceramic coatings offer superior hydrophobic properties, causing water and dirt to bead off easily, reducing cleaning frequency. Both finishes enhance durability, but glass enamel requires less specialized care, while ceramic coatings often need specific cleaners to preserve their protective layer.

Cost Analysis: Value for Money

Glass enamel typically offers a lower initial cost compared to ceramic coatings, making it an attractive option for budget-conscious buyers seeking durability and a glossy finish. Ceramic coatings, while more expensive upfront, provide superior longevity, scratch resistance, and easier maintenance, which can lead to cost savings over time. Evaluating overall value for money depends on the intended use, with glass enamel suited for short- to medium-term projects and ceramic coatings preferred for high-performance, long-term protection.

Environmental Impact: Sustainability Factors

Glass enamel utilizes natural raw materials like silica and soda ash, promoting recyclability and reducing landfill waste, whereas ceramic coatings often require energy-intensive manufacturing processes with synthetic chemicals. The durability and long lifespan of glass enamel contribute to lower resource consumption over time, enhancing sustainability compared to ceramic coatings that may degrade faster and require more frequent reapplications. Reduced volatile organic compound (VOC) emissions during glass enamel production further minimize environmental pollution, supporting eco-friendly manufacturing standards.

glass enamel vs ceramic coating Infographic

materialdif.com

materialdif.com