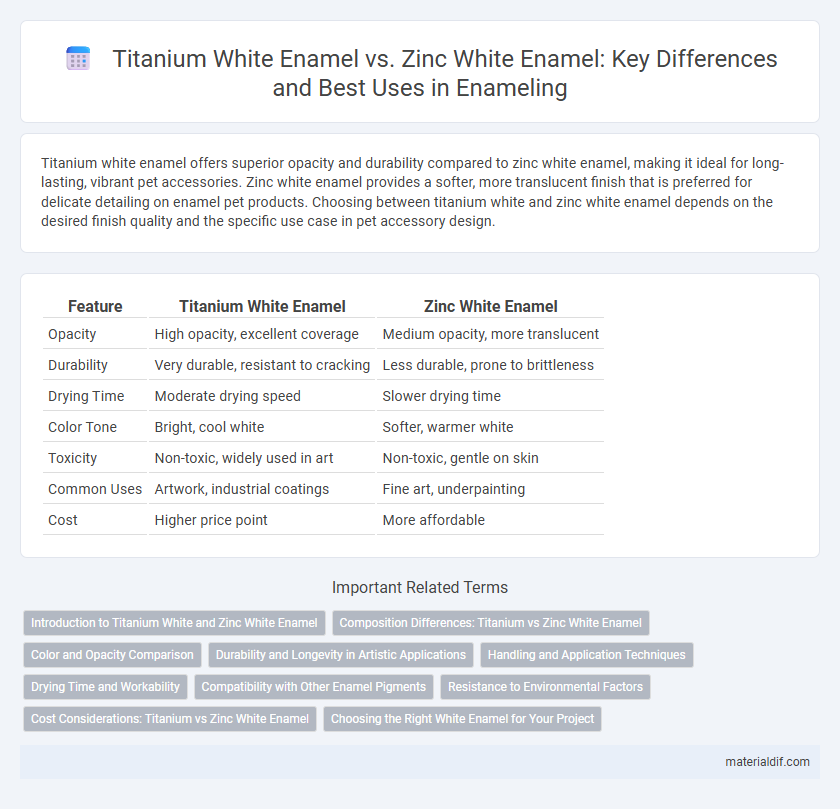

Titanium white enamel offers superior opacity and durability compared to zinc white enamel, making it ideal for long-lasting, vibrant pet accessories. Zinc white enamel provides a softer, more translucent finish that is preferred for delicate detailing on enamel pet products. Choosing between titanium white and zinc white enamel depends on the desired finish quality and the specific use case in pet accessory design.

Table of Comparison

| Feature | Titanium White Enamel | Zinc White Enamel |

|---|---|---|

| Opacity | High opacity, excellent coverage | Medium opacity, more translucent |

| Durability | Very durable, resistant to cracking | Less durable, prone to brittleness |

| Drying Time | Moderate drying speed | Slower drying time |

| Color Tone | Bright, cool white | Softer, warmer white |

| Toxicity | Non-toxic, widely used in art | Non-toxic, gentle on skin |

| Common Uses | Artwork, industrial coatings | Fine art, underpainting |

| Cost | Higher price point | More affordable |

Introduction to Titanium White and Zinc White Enamel

Titanium white enamel offers superior opacity and durability compared to zinc white enamel, making it a preferred choice in coatings and art applications requiring bright, long-lasting finishes. Zinc white enamel provides a cooler, more transparent finish and is valued for its flexibility and resistance to cracking in drying oils. Both pigments serve distinct roles based on their chemical composition and performance characteristics in enamel formulations.

Composition Differences: Titanium vs Zinc White Enamel

Titanium white enamel contains titanium dioxide (TiO2) as the primary pigment, offering superior opacity and brightness compared to zinc white enamel, which uses zinc oxide (ZnO) as its main component. The chemical composition of titanium white enamel provides enhanced durability and better coverage, making it ideal for surfaces requiring high reflectance and longevity. In contrast, zinc white enamel features a more transparent finish with less tinting strength, often preferred for mixing and subtle shading effects.

Color and Opacity Comparison

Titanium white enamel exhibits a brighter, more opaque finish compared to zinc white enamel, making it ideal for achieving high opacity and vivid color coverage. Zinc white enamel offers a cooler, more transparent appearance, which allows underlying colors to subtly influence the final hue. The superior opacity of titanium white enamel enhances paint durability and brightness, while zinc white enamel provides a softer, more flexible finish suitable for glazing techniques.

Durability and Longevity in Artistic Applications

Titanium white enamel offers superior durability and longevity compared to zinc white enamel, making it a preferred choice for artists seeking lasting finishes. Its strong opacity and resistance to yellowing ensure vibrant and stable colors over time in various artistic applications. Zinc white enamel, while less durable and more prone to brittleness and fading, is often used for subtle layering effects but may require more careful preservation to maintain its appearance.

Handling and Application Techniques

Titanium white enamel offers superior opacity and faster drying times, making it ideal for detailed brushwork and smooth layering in intricate applications. Zinc white enamel, known for its slower drying rate and greater transparency, allows for extended blending and smoother gradients, which is beneficial in glazing techniques. Handling titanium white requires careful thinning to avoid cracking, while zinc white demands patience to ensure even coverage without overworking the surface.

Drying Time and Workability

Titanium white enamel offers faster drying times compared to zinc white enamel, making it ideal for projects requiring quick layering or rapid completion. Zinc white enamel provides superior workability with smoother blending properties, favored by artists seeking longer open time for detailed finishes. Both enamels have distinct advantages in drying speed and manipulation, influencing choice based on specific application needs.

Compatibility with Other Enamel Pigments

Titanium white enamel exhibits excellent compatibility with most enamel pigments, providing superior opacity and brightness without altering the intended tonal balance. Zinc white enamel, while offering a more transparent finish, can sometimes react with other pigments, causing reduced adhesion or discoloration over time. Selecting titanium white enamel ensures consistent color stability and durability when mixed with diverse enamel pigments.

Resistance to Environmental Factors

Titanium white enamel exhibits superior resistance to environmental factors such as UV radiation, moisture, and chemical corrosion, ensuring longer-lasting color stability and durability. Zinc white enamel, while offering good opacity, tends to yellow and degrade more quickly under prolonged exposure to sunlight and humidity. The enhanced environmental resistance of titanium white enamel makes it a preferred choice for outdoor and high-exposure applications.

Cost Considerations: Titanium vs Zinc White Enamel

Titanium white enamel generally costs more than zinc white enamel due to its superior opacity, durability, and brightness, making it a preferred choice for high-quality finishes. Zinc white enamel is more affordable but offers lower coverage and can exhibit brittleness, which may lead to cracking over time. Budget-conscious projects often favor zinc white enamel for cost savings, while titanium white enamel is selected for premium results despite the higher price.

Choosing the Right White Enamel for Your Project

Titanium white enamel offers superior opacity and brightness, making it ideal for projects requiring strong coverage and vibrant finishes. Zinc white enamel provides a cooler, more translucent effect with excellent durability and flexibility, suitable for detailed or layered work. Selecting the right white enamel depends on factors like desired opacity, drying time, and surface compatibility to achieve optimal results.

Titanium white enamel vs zinc white enamel Infographic

materialdif.com

materialdif.com