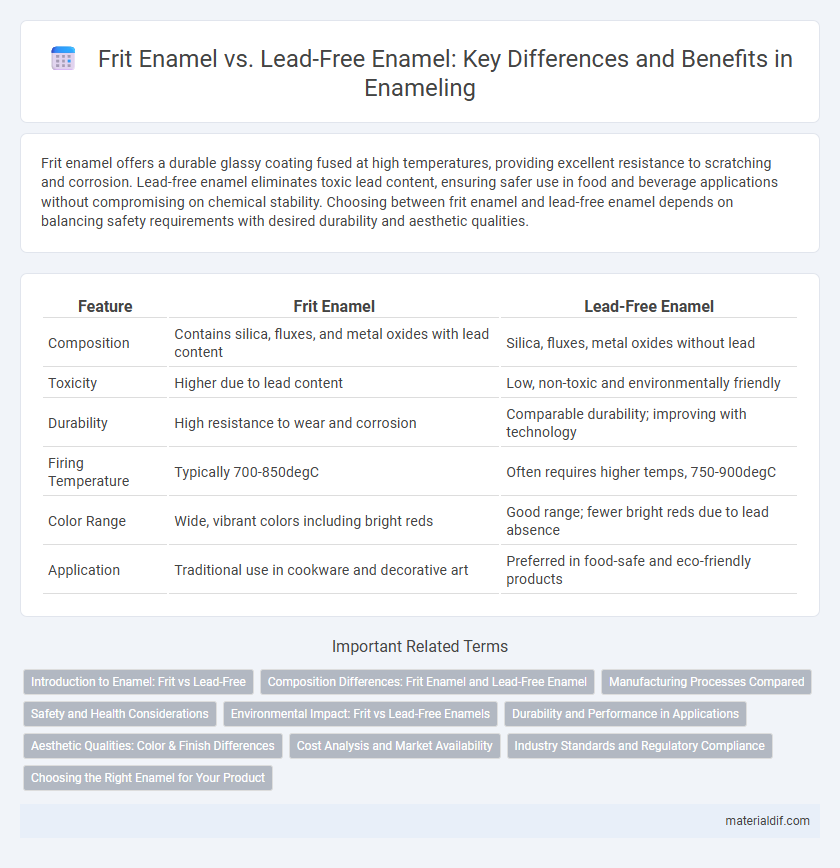

Frit enamel offers a durable glassy coating fused at high temperatures, providing excellent resistance to scratching and corrosion. Lead-free enamel eliminates toxic lead content, ensuring safer use in food and beverage applications without compromising on chemical stability. Choosing between frit enamel and lead-free enamel depends on balancing safety requirements with desired durability and aesthetic qualities.

Table of Comparison

| Feature | Frit Enamel | Lead-Free Enamel |

|---|---|---|

| Composition | Contains silica, fluxes, and metal oxides with lead content | Silica, fluxes, metal oxides without lead |

| Toxicity | Higher due to lead content | Low, non-toxic and environmentally friendly |

| Durability | High resistance to wear and corrosion | Comparable durability; improving with technology |

| Firing Temperature | Typically 700-850degC | Often requires higher temps, 750-900degC |

| Color Range | Wide, vibrant colors including bright reds | Good range; fewer bright reds due to lead absence |

| Application | Traditional use in cookware and decorative art | Preferred in food-safe and eco-friendly products |

Introduction to Enamel: Frit vs Lead-Free

Frit enamel, composed of powdered glass fused at high temperatures, ensures durability and resistance to corrosion, commonly used in industrial applications. Lead-free enamel eliminates toxic lead components, offering an environmentally friendly alternative that adheres to strict health and safety regulations. Both types provide a smooth, glossy finish, but lead-free enamel prioritizes sustainability while maintaining comparable performance to traditional frit enamel.

Composition Differences: Frit Enamel and Lead-Free Enamel

Frit enamel is composed primarily of finely ground glass mixed with fluxes such as borates, soda, and silica, often containing lead oxide to lower melting points and enhance durability. Lead-free enamel, by contrast, replaces lead oxide with alternative fluxes like bismuth, zinc, or potassium compounds to achieve similar melting characteristics while eliminating toxicity. These compositional differences impact firing temperatures, safety standards, and environmental compliance in various industrial applications.

Manufacturing Processes Compared

Frit enamel manufacturing involves melting a mixture of raw materials like silica, fluxes, and colorants at high temperatures, then rapidly cooling them to form a glassy granulate that is ground into powder for coating. Lead-free enamel production replaces lead oxide with safer alternatives such as bismuth oxide or zinc oxide, requiring precise temperature control to ensure proper fusion and durability without compromising enamel quality. Both processes demand advanced kiln technology and rigorous quality control to achieve optimal adhesion, gloss, and chemical resistance in the final enamel coating.

Safety and Health Considerations

Frit enamel, composed of finely ground glass fused with metal oxides, offers durability but may contain lead, posing health risks such as lead poisoning during manufacture or damage. Lead-free enamel eliminates toxic lead compounds, enhancing safety by reducing exposure to harmful substances, making it preferable for food-contact and household items. Regulatory standards increasingly favor lead-free options to ensure user health and environmental protection.

Environmental Impact: Frit vs Lead-Free Enamels

Frit enamel, composed primarily of silica, fluxes, and colorants, often contains trace amounts of heavy metals that can leach into the environment during production and disposal, posing significant ecological risks. Lead-free enamel eliminates the use of toxic lead compounds, significantly reducing hazardous waste and preventing soil and water contamination associated with traditional lead-based frit enamels. The shift towards lead-free formulations supports regulatory compliance and promotes sustainable manufacturing practices by minimizing the environmental footprint of enamel products.

Durability and Performance in Applications

Frit enamel offers superior durability due to its high melting point and strong adhesion properties, making it ideal for industrial applications requiring long-lasting wear resistance. Lead-free enamel provides enhanced safety and environmental benefits without compromising performance, achieving comparable hardness and corrosion resistance suitable for cookware and food-related uses. Both types deliver reliable performance, but choosing between frit and lead-free enamel depends on specific application demands and regulatory standards.

Aesthetic Qualities: Color & Finish Differences

Frit enamel offers vibrant, consistent color with a smooth, glossy finish prized in decorative applications, while lead-free enamel emphasizes safety without sacrificing deep hues and translucency. Lead-free formulations may exhibit slight variations in texture and color depth due to differences in melting points and chemical composition, providing unique aesthetic nuances. The choice between frit and lead-free enamel balances vivid coloration and traditional shine against modern, non-toxic standards and subtle finish variations.

Cost Analysis and Market Availability

Frit enamel offers a cost-effective solution due to its lower raw material expenses and widespread production, making it readily available in global markets. Lead-free enamel, while often pricier because of specialized formulations and regulatory compliance, is gaining market traction due to health and environmental concerns. Price fluctuations in lead-free enamel are influenced by stricter manufacturing standards and limited suppliers, impacting overall affordability and accessibility.

Industry Standards and Regulatory Compliance

Frit enamel, composed of finely ground glass particles fused onto a substrate, adheres to stringent industry standards for durability and safety in applications such as cookware and electronics. Lead-free enamel formulations comply with international regulatory directives, including RoHS and FDA guidelines, ensuring non-toxicity and environmental safety. Manufacturers prioritize lead-free enamel to meet global market demands while maintaining performance standards in corrosion resistance and thermal stability.

Choosing the Right Enamel for Your Product

Frit enamel offers excellent durability and smooth finish, making it ideal for high-wear applications, while lead-free enamel ensures compliance with health and environmental regulations by eliminating toxic lead content. Selecting the right enamel depends on product requirements such as safety standards, appearance, and exposure conditions. Consider lead-free enamel for consumer goods and cookware to prioritize non-toxicity, whereas frit enamel suits industrial uses demanding superior hardness and chemical resistance.

Frit Enamel vs Lead-Free Enamel Infographic

materialdif.com

materialdif.com