Enamel firing involves applying powdered glass to a metal surface and heating it in a kiln to fuse the enamel, creating a durable and glossy coating. Enamel dipping, by contrast, immerses the entire piece into molten enamel, resulting in a thicker, more uniform layer ideal for larger or three-dimensional objects. Choosing between the two methods depends on the desired finish, complexity of the design, and the type of metal substrate used.

Table of Comparison

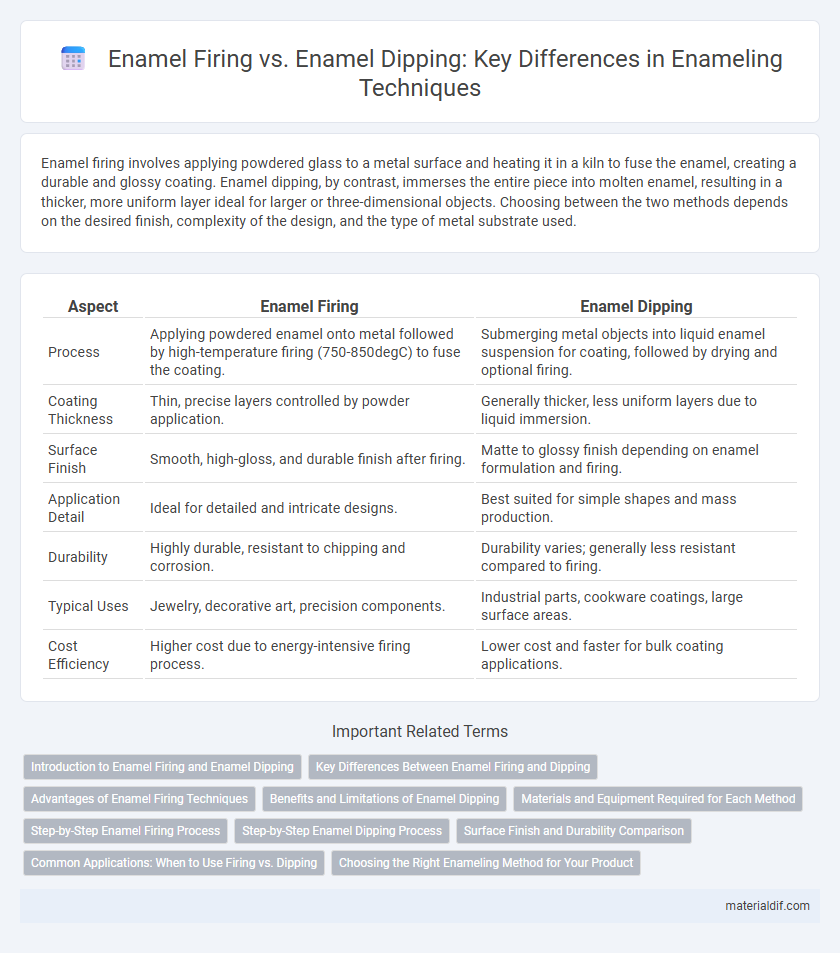

| Aspect | Enamel Firing | Enamel Dipping |

|---|---|---|

| Process | Applying powdered enamel onto metal followed by high-temperature firing (750-850degC) to fuse the coating. | Submerging metal objects into liquid enamel suspension for coating, followed by drying and optional firing. |

| Coating Thickness | Thin, precise layers controlled by powder application. | Generally thicker, less uniform layers due to liquid immersion. |

| Surface Finish | Smooth, high-gloss, and durable finish after firing. | Matte to glossy finish depending on enamel formulation and firing. |

| Application Detail | Ideal for detailed and intricate designs. | Best suited for simple shapes and mass production. |

| Durability | Highly durable, resistant to chipping and corrosion. | Durability varies; generally less resistant compared to firing. |

| Typical Uses | Jewelry, decorative art, precision components. | Industrial parts, cookware coatings, large surface areas. |

| Cost Efficiency | Higher cost due to energy-intensive firing process. | Lower cost and faster for bulk coating applications. |

Introduction to Enamel Firing and Enamel Dipping

Enamel firing involves applying powdered glass onto metal surfaces and then heating them in a kiln at temperatures between 1400degF to 1600degF, causing the enamel to melt and fuse permanently. Enamel dipping, by contrast, entails submerging the metal object directly into a molten enamel bath, creating a uniform coating quickly and efficiently, often used for larger or three-dimensional pieces. Both techniques enhance the durability and aesthetic appeal of metal items by providing a smooth, glass-like finish resistant to corrosion.

Key Differences Between Enamel Firing and Dipping

Enamel firing involves applying powdered enamel to a metal surface and heating it to high temperatures, typically between 1400degF to 1600degF, to fuse the enamel onto the substrate, creating a durable, glass-like coating. Enamel dipping, on the other hand, entails immersing the metal piece into a liquid enamel suspension, followed by drying and firing, which can result in a more uniform but thinner enamel layer. Key differences include the method of application--powder vs. liquid enamel--and control over thickness and texture, with firing offering precise layering and dipping providing rapid, even coverage.

Advantages of Enamel Firing Techniques

Enamel firing techniques provide superior durability and a more uniform coating compared to enamel dipping methods, resulting in enhanced resistance to chipping and wear. The controlled high-temperature firing process ensures better adhesion of the enamel to the substrate, improving longevity and aesthetic quality. Firing also allows for precise color development and smoother finishes, which are critical in high-end decorative applications.

Benefits and Limitations of Enamel Dipping

Enamel dipping offers uniform coating and faster production times by immersing objects directly into molten enamel, making it ideal for complex shapes and mass manufacturing. Benefits include enhanced durability and consistent enamel thickness, but limitations involve potential enamel pooling and less precision compared to enamel firing, which uses controlled heat to fuse enamel powders individually. Enamel dipping may also be unsuitable for items sensitive to thermal shock due to rapid temperature changes during the dipping process.

Materials and Equipment Required for Each Method

Enamel firing requires a kiln capable of reaching temperatures between 1300degF and 1500degF, along with heat-resistant supports such as firing racks or trays made of ceramic or metal. Enamel dipping involves enamel powder or suspension and requires dipping tanks or containers large enough to submerge items, as well as drying racks to let excess enamel dry before firing. Both methods demand proper ventilation, safety equipment like gloves and masks, and the specific type of enamel suited for the chosen technique, with firing necessitating high-temperature durable enamels and dipping often using powder or liquid enamels designed for adhesion.

Step-by-Step Enamel Firing Process

The enamel firing process involves applying powdered glass onto a metal surface and heating it in a kiln at temperatures ranging from 1400 to 1600 degrees Fahrenheit until the enamel melts and fuses to the substrate, creating a durable, glossy finish. This technique requires precise temperature control and timing, typically heating the piece for 1 to 5 minutes depending on the metal and enamel type to avoid burning or underfiring. Enamel dipping, in contrast, simply immerses the metal into liquid enamel but lacks the controlled fusion and durability achieved by the step-by-step firing method, which enhances color vibrancy and adhesion.

Step-by-Step Enamel Dipping Process

The step-by-step enamel dipping process begins with thoroughly cleaning the metal substrate to ensure optimal adhesion, followed by immersing the piece into a liquid enamel slurry to achieve an even coat. After dipping, the item is carefully drained and dried to remove excess enamel before undergoing high-temperature firing in a kiln, typically between 1400degF and 1600degF, which fuses the enamel to the metal surface. This method allows for uniform enamel layers and precise control over thickness compared to enamel firing techniques that apply powder coating directly onto heated surfaces.

Surface Finish and Durability Comparison

Enamel firing produces a smooth, glass-like surface finish with excellent durability due to the high-temperature fusion that bonds the enamel to the metal substrate, creating a hard, wear-resistant coating. Enamel dipping typically results in a thicker coat but may have a less uniform surface finish and slightly lower adhesion strength, which can affect long-term durability under mechanical stress. Therefore, enamel firing is preferred for applications requiring superior surface smoothness and enhanced resistance to chipping and abrasion.

Common Applications: When to Use Firing vs. Dipping

Enamel firing is ideal for intricate designs and durable finishes on metal jewelry and decorative art, providing even heat distribution that enhances color vibrancy and adhesion. Enamel dipping suits production of uniform coatings on industrial components and utensils, offering efficiency for large batches and consistent thickness. Choosing firing or dipping depends on the item's complexity, production scale, and desired durability of the enamel finish.

Choosing the Right Enameling Method for Your Product

Enamel firing involves applying powdered glass to metal and heating it in a kiln to create a durable, glossy surface, ideal for intricate designs and high-temperature-resistant coatings. Enamel dipping, on the other hand, submerges the entire piece into liquid enamel, providing uniform coverage suitable for larger or irregularly shaped items. Selecting between firing and dipping depends on the product's size, design complexity, and production volume to achieve optimal durability and finish quality.

enamel firing vs enamel dipping Infographic

materialdif.com

materialdif.com