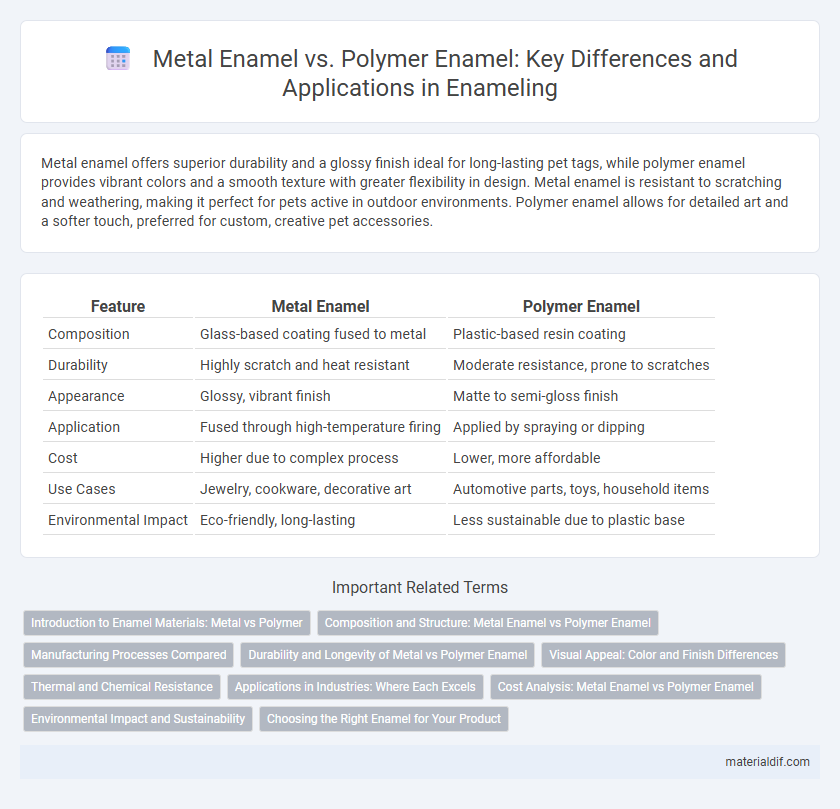

Metal enamel offers superior durability and a glossy finish ideal for long-lasting pet tags, while polymer enamel provides vibrant colors and a smooth texture with greater flexibility in design. Metal enamel is resistant to scratching and weathering, making it perfect for pets active in outdoor environments. Polymer enamel allows for detailed art and a softer touch, preferred for custom, creative pet accessories.

Table of Comparison

| Feature | Metal Enamel | Polymer Enamel |

|---|---|---|

| Composition | Glass-based coating fused to metal | Plastic-based resin coating |

| Durability | Highly scratch and heat resistant | Moderate resistance, prone to scratches |

| Appearance | Glossy, vibrant finish | Matte to semi-gloss finish |

| Application | Fused through high-temperature firing | Applied by spraying or dipping |

| Cost | Higher due to complex process | Lower, more affordable |

| Use Cases | Jewelry, cookware, decorative art | Automotive parts, toys, household items |

| Environmental Impact | Eco-friendly, long-lasting | Less sustainable due to plastic base |

Introduction to Enamel Materials: Metal vs Polymer

Enamel materials are widely used for their durability and aesthetic appeal, with metal enamel typically composed of powdered glass fused onto a metal substrate at high temperatures to create a hard, glossy surface. Polymer enamel, in contrast, consists of synthetic resins that provide flexibility, impact resistance, and ease of application, often used for coatings requiring lighter weight and corrosion protection. The fundamental difference lies in metal enamel's inorganic, heat-fused composition versus polymer enamel's organic, chemically cured nature, influencing their performance in industrial and decorative applications.

Composition and Structure: Metal Enamel vs Polymer Enamel

Metal enamel consists of powdered glass fused to a metal substrate through high-temperature firing, creating a rigid, glossy coating with excellent durability and heat resistance. Polymer enamel, composed of synthetic resins or plastics, forms a flexible and lightweight layer that adheres through curing processes without the need for high heat. Differences in composition and structure result in metal enamel offering superior hardness and chemical resistance, while polymer enamel provides enhanced elasticity and impact absorption.

Manufacturing Processes Compared

Metal enamel manufacturing involves fusing powdered glass to a metal substrate through high-temperature firing, resulting in a durable, glossy finish with excellent resistance to corrosion and heat. Polymer enamel is produced by applying a synthetic resin coating onto surfaces using methods like spraying or dipping, followed by curing at lower temperatures, which offers flexibility and quicker production times. The key distinction lies in metal enamel's thermal fusion process requiring kilns, compared to polymer enamel's reliance on chemical curing processes suitable for temperature-sensitive materials.

Durability and Longevity of Metal vs Polymer Enamel

Metal enamel offers superior durability and longevity compared to polymer enamel due to its resistance to heat, chemicals, and physical abrasion. Polymer enamel tends to degrade faster under exposure to UV light and temperature fluctuations, leading to potential fading and cracking over time. The robust, glass-like coating of metal enamel ensures a longer-lasting finish, making it ideal for applications requiring extended wear and protection.

Visual Appeal: Color and Finish Differences

Metal enamel offers a vibrant, glossy finish with rich, metallic hues that enhance depth and brightness, creating a luxurious and durable visual appeal. Polymer enamel provides a wider color palette with matte and satin finishes, allowing for versatile and contemporary design options. The choice between metal and polymer enamel significantly impacts the final aesthetic, with metal emphasizing brilliance and resilience, while polymer prioritizes texture and color variety.

Thermal and Chemical Resistance

Metal enamel exhibits superior thermal resistance, withstanding temperatures up to 900degC, making it ideal for high-heat industrial applications, while polymer enamel generally resists temperatures only up to 150degC. Chemically, metal enamel provides exceptional resistance to acids, alkalis, and solvents due to its glassy inorganic coating, whereas polymer enamel is more susceptible to degradation from harsh chemicals. This distinct difference in durability and resistance defines metal enamel as the preferred choice for environments demanding robust thermal and chemical protection.

Applications in Industries: Where Each Excels

Metal enamel offers superior durability and high-temperature resistance, making it ideal for industrial applications such as cookware, automotive parts, and electrical equipment. Polymer enamel excels in flexibility and corrosion resistance, commonly used in coatings for consumer electronics, household appliances, and protective layers on metal surfaces. Each type provides specialized benefits, with metal enamel suited for demanding thermal environments and polymer enamel preferred for impact resistance and chemical stability.

Cost Analysis: Metal Enamel vs Polymer Enamel

Metal enamel typically incurs higher initial costs due to the expensive raw materials and complex kiln-firing process required for application, while polymer enamel offers a more cost-effective alternative with lower material and processing expenses. Maintenance costs for metal enamel can accumulate over time because of its susceptibility to chipping and corrosion, whereas polymer enamel provides better durability and resistance, reducing long-term refurbishment expenditures. Selecting between metal and polymer enamel ultimately depends on balancing upfront investment against durability and maintenance needs in specific industrial or artistic applications.

Environmental Impact and Sustainability

Metal enamel, primarily composed of glass fused to a metal substrate, offers high durability and recyclability, reducing landfill waste and energy consumption during recycling. Polymer enamel, made from synthetic resins, often involves more environmentally harmful production processes and less eco-friendly disposal options due to its non-biodegradable nature and challenges in recycling. Sustainable choice leans towards metal enamel for its longer lifespan, lower environmental footprint, and compatibility with circular economy practices.

Choosing the Right Enamel for Your Product

Metal enamel offers superior durability and heat resistance, making it ideal for cookware and industrial applications where long-lasting protection is essential. Polymer enamel provides greater flexibility and color variety, suitable for decorative items and products requiring lightweight coatings. Selecting the right enamel depends on the product's functional requirements, exposure conditions, and aesthetic goals to ensure optimal performance and longevity.

Metal Enamel vs Polymer Enamel Infographic

materialdif.com

materialdif.com