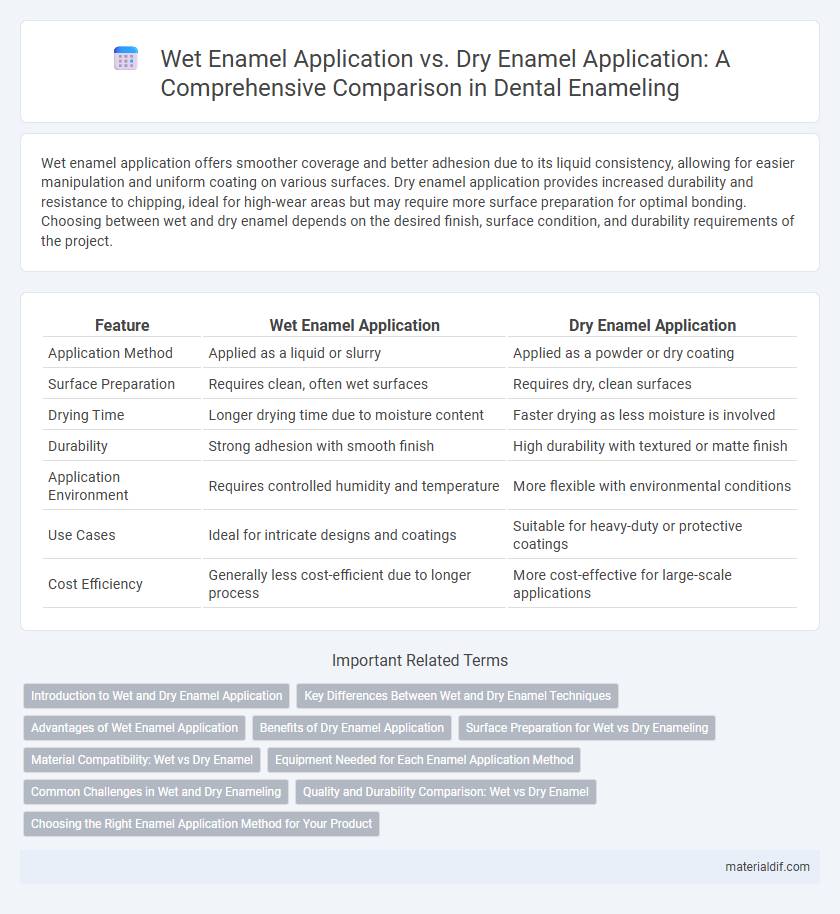

Wet enamel application offers smoother coverage and better adhesion due to its liquid consistency, allowing for easier manipulation and uniform coating on various surfaces. Dry enamel application provides increased durability and resistance to chipping, ideal for high-wear areas but may require more surface preparation for optimal bonding. Choosing between wet and dry enamel depends on the desired finish, surface condition, and durability requirements of the project.

Table of Comparison

| Feature | Wet Enamel Application | Dry Enamel Application |

|---|---|---|

| Application Method | Applied as a liquid or slurry | Applied as a powder or dry coating |

| Surface Preparation | Requires clean, often wet surfaces | Requires dry, clean surfaces |

| Drying Time | Longer drying time due to moisture content | Faster drying as less moisture is involved |

| Durability | Strong adhesion with smooth finish | High durability with textured or matte finish |

| Application Environment | Requires controlled humidity and temperature | More flexible with environmental conditions |

| Use Cases | Ideal for intricate designs and coatings | Suitable for heavy-duty or protective coatings |

| Cost Efficiency | Generally less cost-efficient due to longer process | More cost-effective for large-scale applications |

Introduction to Wet and Dry Enamel Application

Wet enamel application involves using enamel paint in a liquid state, allowing for smooth, even coatings ideal for intricate surfaces and detailed work. Dry enamel application typically refers to powdered enamel that is applied and then fused onto a substrate through high-temperature firing, providing a durable, glossy finish resistant to wear and corrosion. Both methods are chosen based on the project's requirements for adhesion, texture, and durability.

Key Differences Between Wet and Dry Enamel Techniques

Wet enamel application involves applying a liquid enamel mixture that allows for smooth, glossy finishes with intricate detail and color blending, while dry enamel (powdered enamel) is applied as a dry granule and fused by heat, resulting in a textured, durable surface. The wet technique offers greater control over color gradients and is ideal for artistic designs, whereas dry enamel provides enhanced wear resistance suitable for industrial applications. Differences also include drying time, with wet enamel requiring longer curing phases compared to the rapid fusion process of dry enamel.

Advantages of Wet Enamel Application

Wet enamel application offers superior adhesion and a smoother finish due to the enamel's liquid consistency, allowing better coverage of surfaces and intricate details. It enables faster drying times and enhanced flexibility, reducing the risk of cracking or chipping compared to dry enamel. This method is ideal for industrial and artistic purposes where durability and aesthetic quality are critical.

Benefits of Dry Enamel Application

Dry enamel application offers enhanced adhesion and durability compared to wet enamel, resulting in longer-lasting finishes resistant to chipping and wear. It provides superior control over texture and coating thickness, ensuring uniform coverage and reducing the risk of runs or drips. This method also minimizes solvent emissions, making it an environmentally friendlier option suitable for sensitive manufacturing environments.

Surface Preparation for Wet vs Dry Enameling

Wet enamel application requires a thoroughly cleaned and slightly roughened surface to ensure optimal adhesion and avoid issues like blistering or peeling. Dry enamel application typically demands a denser, more meticulously prepared surface, often involving abrasive blasting or sanding to create a key that allows the powdered enamel to bond effectively during firing. Proper surface preparation enhances coating durability and finish quality, directly impacting the enamel's performance in both wet and dry methods.

Material Compatibility: Wet vs Dry Enamel

Wet enamel application offers superior adhesion on porous and uneven surfaces due to its liquid consistency, which allows better penetration and bonding with materials like metal, glass, or ceramics. Dry enamel application, typically involving powdered enamel frits, requires precise heat control to ensure proper fusion on heat-resistant substrates such as cast iron or steel. Each method demands careful consideration of substrate thermal tolerance and surface texture to achieve optimal material compatibility and durable enamel finishes.

Equipment Needed for Each Enamel Application Method

Wet enamel application requires spray guns, air compressors, and ventilation systems to ensure even coating and safe handling of liquid materials. Dry enamel application involves electrostatic powder coating equipment, including powder spray guns, booths with powder recovery systems, and curing ovens to fuse the powder onto surfaces. Each method demands specialized machinery designed to optimize adhesion, finish quality, and environmental safety.

Common Challenges in Wet and Dry Enameling

Wet enamel application often faces challenges such as uneven coating thickness, longer drying times, and susceptibility to dust contamination, which can affect the final surface quality. Dry enamel application struggles with achieving consistent adhesion and uniform coverage, as well as potential issues with particle agglomeration and inconsistent curing. Both methods require precise control of environmental conditions and application techniques to minimize defects like cracking, bubbling, and color inconsistencies.

Quality and Durability Comparison: Wet vs Dry Enamel

Wet enamel application offers superior adhesion and a smoother finish due to its fluid consistency, enhancing overall coating quality. Dry enamel tends to be less uniform, increasing the risk of surface imperfections and reduced durability. Consequently, wet enamel coatings typically exhibit greater resistance to chipping and environmental wear compared to their dry enamel counterparts.

Choosing the Right Enamel Application Method for Your Product

Choosing the right enamel application method for your product depends on factors like surface type, desired finish, and production efficiency. Wet enamel application offers superior coverage, vibrant color depth, and flexibility for complex surfaces, making it ideal for decorative and high-quality products. Dry enamel application provides faster drying times and durability, suited for industrial and high-volume manufacturing where abrasion resistance is critical.

Wet enamel application vs Dry enamel application Infographic

materialdif.com

materialdif.com