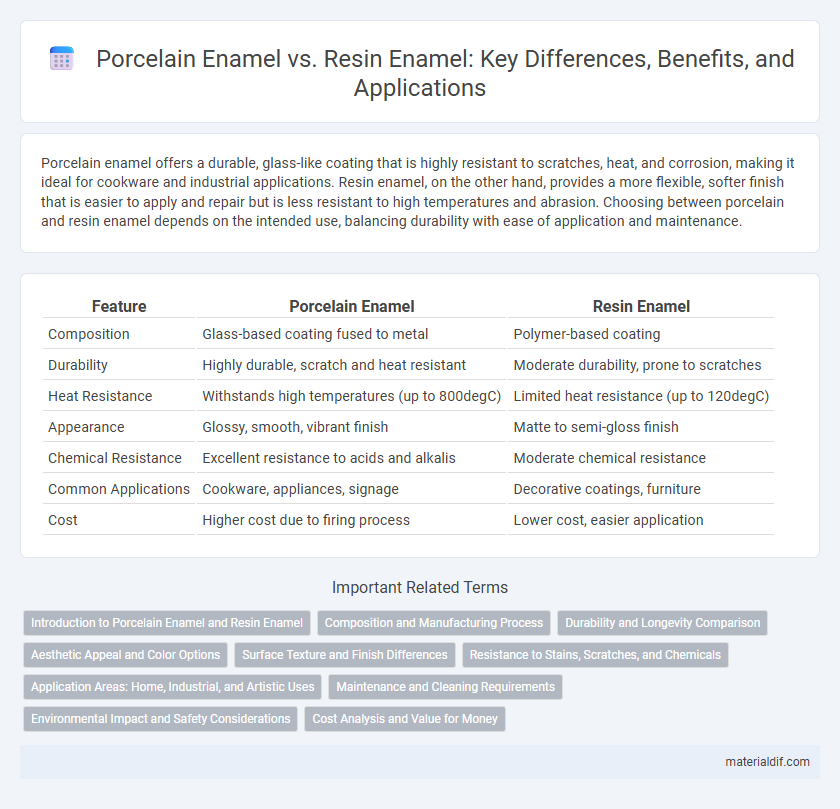

Porcelain enamel offers a durable, glass-like coating that is highly resistant to scratches, heat, and corrosion, making it ideal for cookware and industrial applications. Resin enamel, on the other hand, provides a more flexible, softer finish that is easier to apply and repair but is less resistant to high temperatures and abrasion. Choosing between porcelain and resin enamel depends on the intended use, balancing durability with ease of application and maintenance.

Table of Comparison

| Feature | Porcelain Enamel | Resin Enamel |

|---|---|---|

| Composition | Glass-based coating fused to metal | Polymer-based coating |

| Durability | Highly durable, scratch and heat resistant | Moderate durability, prone to scratches |

| Heat Resistance | Withstands high temperatures (up to 800degC) | Limited heat resistance (up to 120degC) |

| Appearance | Glossy, smooth, vibrant finish | Matte to semi-gloss finish |

| Chemical Resistance | Excellent resistance to acids and alkalis | Moderate chemical resistance |

| Common Applications | Cookware, appliances, signage | Decorative coatings, furniture |

| Cost | Higher cost due to firing process | Lower cost, easier application |

Introduction to Porcelain Enamel and Resin Enamel

Porcelain enamel is a glassy, inorganic coating fused onto metal at high temperatures, known for its durability, heat resistance, and glossy finish. Resin enamel, composed of synthetic polymer resins, offers flexibility, quicker curing times, and impact resistance but generally lacks the heat resistance of porcelain enamel. Both materials are widely used for protective and decorative coatings in appliances, cookware, and architectural applications.

Composition and Manufacturing Process

Porcelain enamel consists of powdered glass fused to metal at high temperatures, creating a durable, hard coating resistant to corrosion and heat, ideal for cookware and industrial applications. Resin enamel is made from synthetic polymers cured at lower temperatures, offering flexibility, chemical resistance, and easier application for appliances and automotive parts. The key difference lies in porcelain enamel's vitrification process versus resin enamel's polymerization, influencing their performance and usage.

Durability and Longevity Comparison

Porcelain enamel offers superior durability and longevity compared to resin enamel due to its glass-like coating fused to metal at high temperatures, making it highly resistant to scratches, corrosion, and UV damage. Resin enamel, while flexible and easier to apply, tends to wear down faster and is more susceptible to fading, chipping, and environmental degradation over time. For applications requiring long-term performance and minimal maintenance, porcelain enamel is the preferred option.

Aesthetic Appeal and Color Options

Porcelain enamel offers a superior aesthetic appeal with its glossy, glass-like finish that resists fading and provides vibrant, long-lasting color options suitable for both indoor and outdoor applications. Resin enamel, while more flexible and less expensive, tends to have a matte or semi-gloss finish with limited color durability, making it ideal for short-term or indoor projects. The choice between porcelain and resin enamel significantly impacts the visual quality and color retention of coatings in architectural and decorative uses.

Surface Texture and Finish Differences

Porcelain enamel offers a smooth, glass-like surface with a high-gloss finish that resists scratches and stains, providing durability and an elegant appearance. Resin enamel typically has a softer, matte or semi-gloss finish with a slightly textured feel, which can be more prone to wear and surface damage over time. The choice between porcelain and resin enamel significantly impacts the aesthetic and maintenance requirements of coated surfaces.

Resistance to Stains, Scratches, and Chemicals

Porcelain enamel exhibits superior resistance to stains, scratches, and harsh chemicals compared to resin enamel, making it ideal for durable surfaces in kitchens and laboratories. Its hard, glass-like coating resists discoloration and abrasion, maintaining appearance over time. Resin enamel, while offering some flexibility and ease of application, tends to be more susceptible to chemical damage and surface scratches.

Application Areas: Home, Industrial, and Artistic Uses

Porcelain enamel is predominantly used in industrial applications such as cookware, appliances, and architectural panels due to its durability, chemical resistance, and glossy finish. Resin enamel, favored for home and artistic uses, offers flexibility, quick drying, and a variety of color options suited for decorative painting, furniture, and crafts. Both materials serve distinct roles: porcelain enamel excels in heavy-duty, heat-resistant environments, while resin enamel is preferred for creative designs and lower-temperature applications.

Maintenance and Cleaning Requirements

Porcelain enamel offers superior resistance to stains and scratches, requiring only gentle cleaning with mild detergents and non-abrasive sponges to maintain its glossy, durable surface. Resin enamel, while easier to apply and more flexible, demands more frequent cleaning and careful avoidance of harsh chemicals or abrasive materials to prevent surface degradation and discoloration. Proper maintenance of porcelain enamel ensures long-lasting aesthetics and functionality, whereas resin enamel may show wear faster if not cleaned regularly and properly.

Environmental Impact and Safety Considerations

Porcelain enamel, composed of powdered glass fused to metal at high temperatures, offers excellent durability and resistance to chemicals, making it a safer choice with minimal environmental impact due to its inert, non-toxic nature and long lifespan. Resin enamel, typically made from organic polymers, often contains volatile organic compounds (VOCs) that can contribute to air pollution and pose health risks during application and curing processes. The disposal and degradation of resin enamel may release hazardous substances, whereas porcelain enamel surfaces generally avoid such environmental concerns thanks to their stable, non-reactive composition.

Cost Analysis and Value for Money

Porcelain enamel typically involves higher upfront costs compared to resin enamel due to its durability and resistance to scratching, heat, and chemicals, making it ideal for long-term applications. Resin enamel offers a lower initial investment with easier application and repair processes but may require more frequent maintenance and replacement over time. Evaluating cost analysis reveals that porcelain enamel provides better value for money in heavy-use or high-wear environments, while resin enamel suits budget-conscious projects with less demanding conditions.

Porcelain enamel vs resin enamel Infographic

materialdif.com

materialdif.com