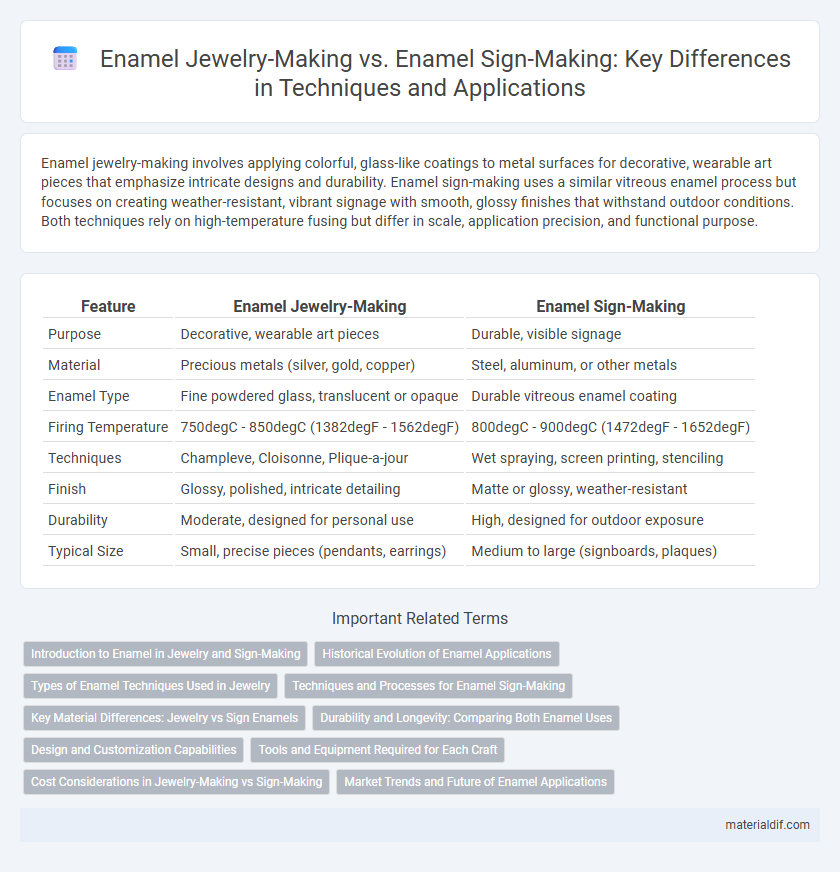

Enamel jewelry-making involves applying colorful, glass-like coatings to metal surfaces for decorative, wearable art pieces that emphasize intricate designs and durability. Enamel sign-making uses a similar vitreous enamel process but focuses on creating weather-resistant, vibrant signage with smooth, glossy finishes that withstand outdoor conditions. Both techniques rely on high-temperature fusing but differ in scale, application precision, and functional purpose.

Table of Comparison

| Feature | Enamel Jewelry-Making | Enamel Sign-Making |

|---|---|---|

| Purpose | Decorative, wearable art pieces | Durable, visible signage |

| Material | Precious metals (silver, gold, copper) | Steel, aluminum, or other metals |

| Enamel Type | Fine powdered glass, translucent or opaque | Durable vitreous enamel coating |

| Firing Temperature | 750degC - 850degC (1382degF - 1562degF) | 800degC - 900degC (1472degF - 1652degF) |

| Techniques | Champleve, Cloisonne, Plique-a-jour | Wet spraying, screen printing, stenciling |

| Finish | Glossy, polished, intricate detailing | Matte or glossy, weather-resistant |

| Durability | Moderate, designed for personal use | High, designed for outdoor exposure |

| Typical Size | Small, precise pieces (pendants, earrings) | Medium to large (signboards, plaques) |

Introduction to Enamel in Jewelry and Sign-Making

Enamel in jewelry-making involves fusing powdered glass to metal surfaces through high heat, creating intricate and colorful designs that enhance aesthetic appeal and durability. In contrast, enamel sign-making uses similar techniques to produce weather-resistant, vibrant signs with long-lasting gloss and color retention. Both crafts rely on precise temperature control and quality enamel powders to achieve their distinct functional and artistic outcomes.

Historical Evolution of Enamel Applications

Enamel jewelry-making has evolved from ancient techniques dating back to the Byzantine era, emphasizing intricate cloisonne and champleve methods to create detailed, colorful ornamental pieces. Enamel sign-making emerged later, gaining prominence in the 19th century with industrial advancements that allowed durable, weather-resistant signage for commercial and public use. Both applications showcase enamel's versatility, but jewelry focused on artistic expression while sign-making prioritized functionality and mass production during their historical development.

Types of Enamel Techniques Used in Jewelry

Enamel jewelry-making primarily employs techniques such as cloisonne, champleve, plique-a-jour, and basse-taille, each offering distinct aesthetic effects through intricate metalwork and vibrant glass powders. Cloisonne involves creating compartments with wire to hold enamel, while champleve uses engraved recesses filled with enamel. Plique-a-jour produces a stained-glass effect without a backing, and basse-taille features detailed metal engraving beneath translucent enamel for depth and luminosity.

Techniques and Processes for Enamel Sign-Making

Enamel sign-making employs techniques such as cloisonne, champleve, and powder-coating, which involve fusing powdered glass to metal surfaces at high temperatures, creating durable and vibrant signage. The process requires precise metal preparation, application of enamel layers, and multiple firings to ensure color depth and weather resistance essential for outdoor displays. This differs from enamel jewelry-making, which often emphasizes intricate detailing and smaller scale craftsmanship tailored for aesthetic wearables.

Key Material Differences: Jewelry vs Sign Enamels

Jewelry enamels are typically formulated with fine glass powders and metal oxides to achieve vibrant, translucent colors and a smooth, glossy finish suitable for detailed, small-scale applications. Sign enamels use more robust, durable materials with coarser glass particles and chemical additives designed to withstand harsh outdoor conditions, such as UV exposure and weathering. The primary material difference lies in the enamel's composition and thickness, with jewelry enamels prioritizing aesthetic finesse and sign enamels focusing on longevity and resistance to environmental factors.

Durability and Longevity: Comparing Both Enamel Uses

Enamel jewelry-making typically uses fine glass powders fused at high temperatures on metal surfaces, resulting in pieces with exceptional durability and resistance to tarnish over time. In contrast, enamel sign-making involves thicker layers of enamel applied to steel, designed to endure harsh outdoor environments, offering superior longevity against weathering and corrosion. While both processes optimize enamel's protective qualities, jewelry enamel prioritizes intricate detail and wear resistance, whereas sign enamel emphasizes robustness and long-term exposure durability.

Design and Customization Capabilities

Enamel jewelry-making offers intricate, small-scale designs with high customization flexibility in color blending and fine detailing, ideal for personal accessories. Enamel sign-making emphasizes larger, more durable surfaces with bold, vivid colors and simpler designs optimized for visibility and long-term outdoor use. Both crafts utilize enamel's color-rich properties but differ significantly in scale, detail precision, and functional customization.

Tools and Equipment Required for Each Craft

Enamel jewelry-making requires precision tools such as fine brushes, tweezers, kilns with controlled temperatures, and delicate molds to shape and fuse glass powders onto metal surfaces. Enamel sign-making demands larger-scale equipment, including torch or furnace kilns for even enamel firing on metal sheets, rollers or rollers for applying multiple enamel layers, and heavy-duty scrapers or grinders for surface finishing. Both crafts involve heat-resistant tools but differ significantly in scale and the specificity of equipment tailored to intricate jewelry details versus expansive signage surfaces.

Cost Considerations in Jewelry-Making vs Sign-Making

Enamel jewelry-making typically incurs higher costs due to the use of precious metals like gold and silver, intricate designs, and labor-intensive handcrafting techniques. In contrast, enamel sign-making generally involves larger scale production with more affordable base materials such as steel or aluminum, resulting in lower per-unit expenses. The cost disparity also stems from the detailed precision required for jewelry, whereas signs prioritize durability and visibility over fine craftsmanship.

Market Trends and Future of Enamel Applications

Enamel jewelry-making continues to grow with increasing demand for personalized, handcrafted pieces, driven by a market valuing artisanal quality and unique designs. The enamel sign-making sector, boosted by urban revitalization projects and rising interest in vintage and durable signage, demonstrates steady growth through commercial and hospitality industries. Future enamel applications are expected to expand into smart materials and sustainable manufacturing, leveraging enamel's durability and vibrant aesthetics across both jewelry and signage markets.

Enamel Jewelry-Making vs Enamel Sign-Making Infographic

materialdif.com

materialdif.com