Enamel frit consists of pre-melted, granulated glass particles that provide consistent melting and smoother finishes in enamel applications. Enamel slurry is a liquid suspension of fine enamel powders mixed with water, allowing for precise application on intricate surfaces. Choosing between frit and slurry depends on the required texture, coverage, and ease of use in the enameling process.

Table of Comparison

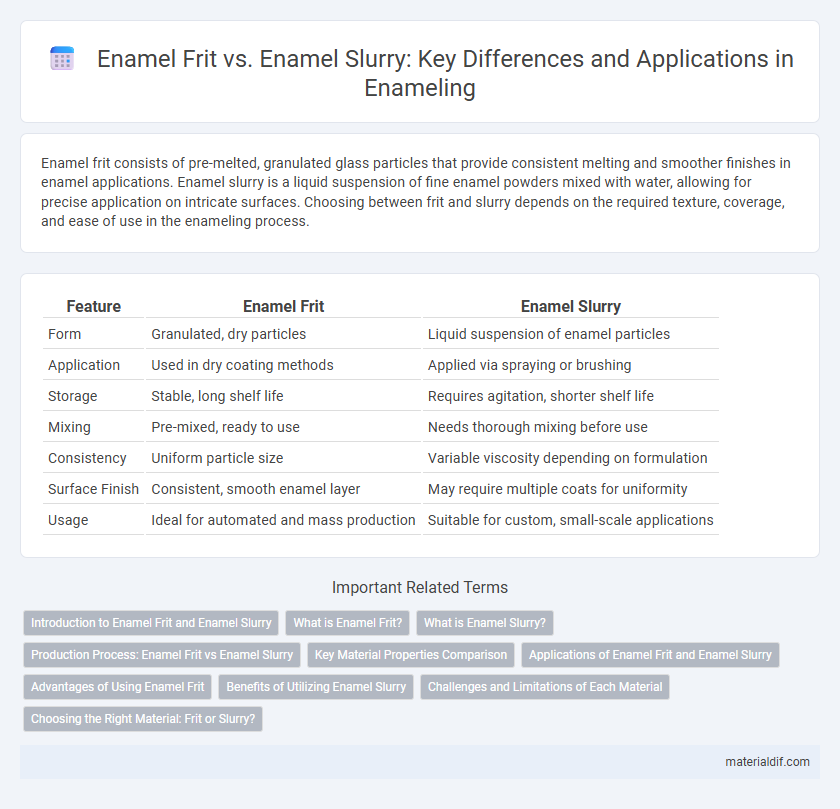

| Feature | Enamel Frit | Enamel Slurry |

|---|---|---|

| Form | Granulated, dry particles | Liquid suspension of enamel particles |

| Application | Used in dry coating methods | Applied via spraying or brushing |

| Storage | Stable, long shelf life | Requires agitation, shorter shelf life |

| Mixing | Pre-mixed, ready to use | Needs thorough mixing before use |

| Consistency | Uniform particle size | Variable viscosity depending on formulation |

| Surface Finish | Consistent, smooth enamel layer | May require multiple coats for uniformity |

| Usage | Ideal for automated and mass production | Suitable for custom, small-scale applications |

Introduction to Enamel Frit and Enamel Slurry

Enamel frit consists of powdered glass particles fused at high temperatures and cooled into solid granules, serving as the raw material for producing vitreous coatings on metals and ceramics. Enamel slurry is a suspension of these frit particles mixed with water and additives, formulated for easier application through spraying, brushing, or dipping processes. Understanding the composition and physical state differences between enamel frit and slurry is critical for optimizing enamel coating performance and achieving desired surface properties.

What is Enamel Frit?

Enamel frit is a pre-melted, granulated glass material used in the enameling process to create a smooth, durable coating on metal surfaces. It consists of finely ground glass particles fused at high temperatures, providing a consistent composition and preventing crystallization during firing. This controlled form allows for precise color and texture application compared to enamel slurry, which is a mixture of ground frit and water used for brush or spray application.

What is Enamel Slurry?

Enamel slurry is a suspension of finely ground enamel frit particles mixed with water or other liquids to create a fluid medium suitable for application on metal, glass, or ceramics before firing. It offers precise control over coating thickness and improves adhesion compared to dry frit, enhancing the final enamel finish's durability and appearance. Used extensively in industrial and artistic enameling processes, enamel slurry ensures uniform coverage and consistency in the fired enamel layer.

Production Process: Enamel Frit vs Enamel Slurry

Enamel frit is produced by melting raw materials at high temperatures, then rapidly cooling and crushing the resulting glassy material into granules, ensuring consistent chemical composition and particle size. Enamel slurry, on the other hand, is created by mixing enamel frit granules with water and additives to form a fluid suspension suitable for application techniques like spraying or brushing. The production process differences impact the material's handling, application method, and final coating properties in industrial enameling.

Key Material Properties Comparison

Enamel frit consists of pre-melted, granulated glass particles offering consistent chemical composition, rapid fusion, and enhanced durability suitable for high-temperature applications. Enamel slurry, a suspension of finely ground enamel powders in liquid, provides better application control and uniform coating thickness but may require longer firing times due to higher moisture content. Comparing key properties, frit delivers superior hardness and thermal resistance, while slurry excels in adhesion and surface smoothness, influencing final enamel quality.

Applications of Enamel Frit and Enamel Slurry

Enamel frit is commonly used in industrial applications such as coating metals for corrosion resistance, decorative finishes, and insulation due to its stable powdered form that melts during firing to form a glassy surface. Enamel slurry, being a suspension of frit particles in water, is primarily applied in processes requiring uniform application like dipping, spraying, and touch-up coatings, enabling precise control over layer thickness and smooth finishes. Both forms are essential in ceramics, electronics, and cookware industries, where the choice between frit and slurry depends on the application method and desired finish quality.

Advantages of Using Enamel Frit

Enamel frit offers superior durability and consistency compared to enamel slurry, providing a more stable and uniform coating essential for high-quality finishes. The granular form of enamel frit ensures better melting and fusion during firing, resulting in enhanced surface hardness and resistance to chipping and corrosion. Industrial applications benefit from enamel frit's improved storage life and ease of handling, reducing waste and improving overall manufacturing efficiency.

Benefits of Utilizing Enamel Slurry

Enamel slurry offers enhanced adhesion and uniform coating due to its finely suspended particles, resulting in smoother, defect-free surfaces compared to enamel frit. The slurry form simplifies application processes, reducing material wastage and enabling more precise control over thickness and texture. This method improves efficiency and consistency in manufacturing ceramic and glass products, delivering superior durability and aesthetic quality.

Challenges and Limitations of Each Material

Enamel frit presents challenges such as inconsistent melting behavior and difficulty in achieving uniform particle size, which can result in uneven coating and defects during firing. Enamel slurry, while offering better dispersion and ease of application, faces limitations like shorter shelf life, sedimentation issues, and the potential for inconsistent viscosity affecting application quality. Both materials require precise control of processing conditions to minimize defects and ensure a durable, high-quality enamel finish.

Choosing the Right Material: Frit or Slurry?

Enamel frit consists of pre-melted, crushed glass particles offering greater stability, consistent particle size, and ease of handling for precise application, making it ideal for controlled coating processes. Enamel slurry is a mixture of ground glass, water, and additives that provides flexibility in adjusting viscosity and particle suspension, suitable for complex shapes and varied application techniques. Selecting between frit and slurry depends on the specific requirements of firing temperature, surface complexity, and desired finish quality in enamel coating projects.

Enamel Frit vs Enamel Slurry Infographic

materialdif.com

materialdif.com