Enamel frit is a powdered glass material used in the vitreous coating process, offering superior durability and resistance to heat and chemicals compared to enamel paint. Enamel paint, composed of pigments suspended in a solvent-based binder, provides a smoother finish ideal for decorative applications but with less toughness and longevity. Choosing between enamel frit and enamel paint depends on whether the project demands high durability or aesthetic flexibility.

Table of Comparison

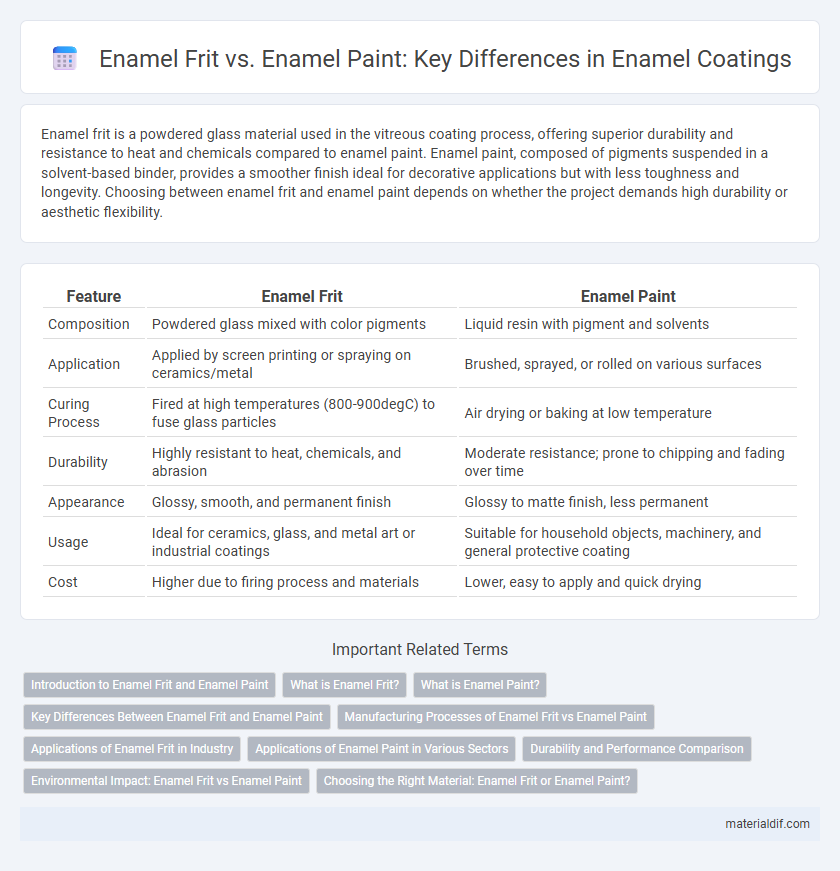

| Feature | Enamel Frit | Enamel Paint |

|---|---|---|

| Composition | Powdered glass mixed with color pigments | Liquid resin with pigment and solvents |

| Application | Applied by screen printing or spraying on ceramics/metal | Brushed, sprayed, or rolled on various surfaces |

| Curing Process | Fired at high temperatures (800-900degC) to fuse glass particles | Air drying or baking at low temperature |

| Durability | Highly resistant to heat, chemicals, and abrasion | Moderate resistance; prone to chipping and fading over time |

| Appearance | Glossy, smooth, and permanent finish | Glossy to matte finish, less permanent |

| Usage | Ideal for ceramics, glass, and metal art or industrial coatings | Suitable for household objects, machinery, and general protective coating |

| Cost | Higher due to firing process and materials | Lower, easy to apply and quick drying |

Introduction to Enamel Frit and Enamel Paint

Enamel frit is a powdered glass material fused onto metal substrates through high-temperature firing, creating a durable, glossy, and chemically resistant coating ideal for industrial applications. Enamel paint consists of pigmented oils or synthetic resins that air-dry to form a hard, glossy finish used primarily for decorative and protective purposes on various surfaces. Both materials offer enamel-like finishes but differ significantly in composition, application processes, and durability characteristics.

What is Enamel Frit?

Enamel frit is a powdered glass material fused with pigments and ground into fine granules used to coat surfaces, often in ceramics, metals, and glass art. Unlike enamel paint, which is liquid and dries to form a hard shell, enamel frit requires heat to melt and bond permanently to substrates, providing durable, glossy finishes resistant to wear, corrosion, and chemicals. Its composition includes silica, fluxes, and colorants, making enamel frit essential in industrial applications such as cookware coatings and decorative art pieces.

What is Enamel Paint?

Enamel paint is a type of paint that dries to a hard, glossy finish, typically composed of synthetic resins dissolved in a solvent. It is formulated to provide durability, resistance to moisture and abrasion, making it ideal for surfaces like metal, wood, and ceramics. Unlike enamel frit, which is used in glass and ceramic firing processes, enamel paint is applied as a liquid coating for protective and decorative purposes.

Key Differences Between Enamel Frit and Enamel Paint

Enamel frit consists of finely ground glass material used as a raw ingredient in the production of enamel coatings, providing durability and heat resistance once fused onto surfaces. Enamel paint contains enamel frit particles suspended in a solvent base, designed for direct application, offering easy use and a glossy, protective finish on various surfaces. The key differences lie in their form and purpose: enamel frit serves as a foundational component melted during the enameling process, while enamel paint is a ready-to-use coating for decorative and protective purposes.

Manufacturing Processes of Enamel Frit vs Enamel Paint

Enamel frit is produced by melting raw materials such as silica, soda ash, and metal oxides at high temperatures to form a glassy, granulated substance that is then ground into powder for application. Enamel paint, on the other hand, is manufactured by blending pigments, resins, and solvents into a liquid medium, allowing for easy application and drying on surfaces. The manufacturing process of enamel frit involves thermal fusion, while enamel paint production focuses on chemical formulation and suspension stability.

Applications of Enamel Frit in Industry

Enamel frit is extensively used in the manufacturing of glass and ceramics, providing durable, heat-resistant coatings that withstand high temperatures and harsh environmental conditions. It plays a crucial role in the automotive and electronics industries for protective and decorative surface treatments, enhancing product longevity and aesthetic appeal. Unlike enamel paint, enamel frit fuses onto surfaces during firing, ensuring superior adhesion and resistance to chipping and fading in industrial applications.

Applications of Enamel Paint in Various Sectors

Enamel paint is widely used in automotive, industrial, and household sectors due to its durability, glossy finish, and resistance to moisture and chemicals. It is ideal for coating metal surfaces, furniture, appliances, and outdoor structures, offering long-lasting protection and aesthetic appeal. In comparison to enamel frit, enamel paint provides easier application and versatility across diverse materials and environments.

Durability and Performance Comparison

Enamel frit exhibits superior durability compared to enamel paint due to its glassy nature that resists scratching, chipping, and fading under harsh conditions. Enamel paint offers easy application and vibrant color options but tends to degrade faster when exposed to UV light and chemicals. Performance-wise, enamel frit is ideal for industrial applications requiring long-lasting, weather-resistant coatings, whereas enamel paint suits decorative or indoor uses with moderate wear.

Environmental Impact: Enamel Frit vs Enamel Paint

Enamel frit is composed of powdered glass fused at high temperatures, resulting in a durable, non-toxic coating with minimal environmental impact due to its long lifespan and inert nature. Enamel paint, however, often contains volatile organic compounds (VOCs) and solvents that contribute to air pollution and require careful disposal to prevent soil and water contamination. Choosing enamel frit over enamel paint reduces environmental hazards by eliminating harmful emissions and decreasing the frequency of recoating and waste generation.

Choosing the Right Material: Enamel Frit or Enamel Paint?

Enamel frit, consisting of finely ground glass particles fused onto surfaces at high temperatures, offers superior durability, heat resistance, and a glossy finish compared to enamel paint, which is a pigmented liquid coating applied and dried at ambient temperatures. When selecting between enamel frit and enamel paint, consider environmental exposure, surface type, and desired longevity; enamel frit is ideal for industrial applications requiring abrasion resistance and permanent adhesion, while enamel paint suits decorative uses with easier application and touch-ups. Cost and equipment availability also influence the choice, as enamel frit demands kiln firing, whereas enamel paint requires minimal specialized tools.

Enamel Frit vs Enamel Paint Infographic

materialdif.com

materialdif.com