Enamel pet products exhibit superior chip resistance due to their durable, fused glass coating that prevents flaking or cracking upon impact, making them ideal for long-lasting use. Scratch resistance in enamel pets is moderate, as the smooth, hard surface resists minor abrasions but can still show fine marks from sharp or abrasive objects. Understanding the distinction between chip resistance and scratch resistance helps in choosing enamel pet items that best match your durability requirements.

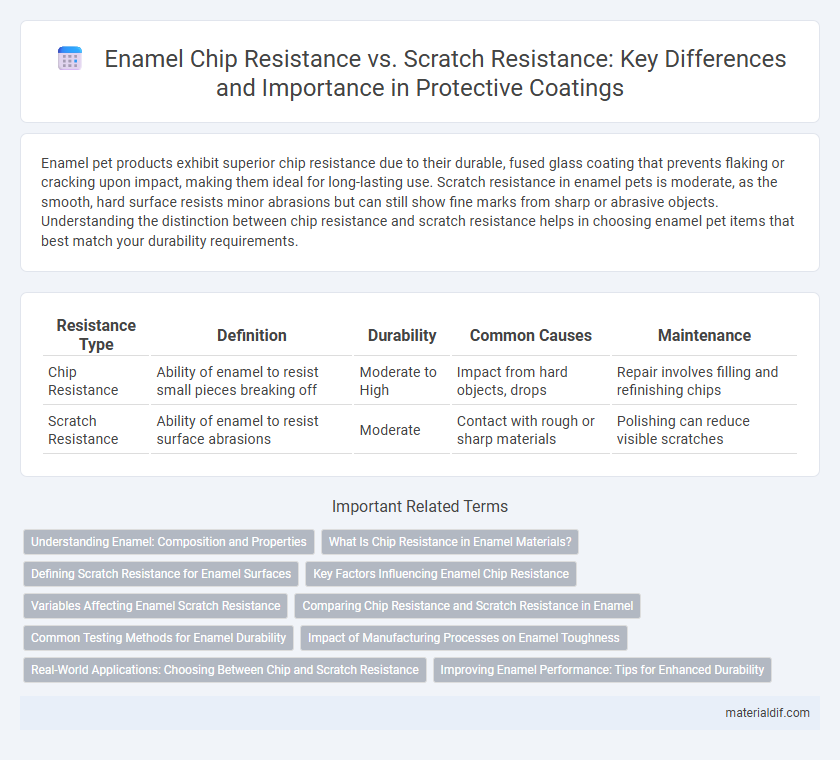

Table of Comparison

| Resistance Type | Definition | Durability | Common Causes | Maintenance |

|---|---|---|---|---|

| Chip Resistance | Ability of enamel to resist small pieces breaking off | Moderate to High | Impact from hard objects, drops | Repair involves filling and refinishing chips |

| Scratch Resistance | Ability of enamel to resist surface abrasions | Moderate | Contact with rough or sharp materials | Polishing can reduce visible scratches |

Understanding Enamel: Composition and Properties

Enamel's chip resistance is influenced by its glassy, brittle composition, which makes it prone to cracking under sudden impact but highly resistant to deep surface damage. Scratch resistance depends on the hardness of the enamel's silica and metal oxide components, allowing it to withstand abrasion without surface alteration. Understanding the balance between enamel's unique vitreous structure and its mineral hardness is key to optimizing durability in applications like dental coatings and cookware.

What Is Chip Resistance in Enamel Materials?

Chip resistance in enamel materials refers to the ability of the surface to withstand impacts and sudden forces without breaking or flaking. This property is critical in environments where enamel-coated items face frequent knocks, helping maintain the integrity and appearance over time. Unlike scratch resistance, which protects against surface abrasions, chip resistance ensures the enamel's structural durability against physical shocks.

Defining Scratch Resistance for Enamel Surfaces

Scratch resistance for enamel surfaces refers to the material's ability to withstand superficial damage caused by sharp or abrasive objects, preserving the surface's aesthetic and functional qualities. This property is critical in maintaining the smooth, glossy finish characteristic of high-quality enamel, as scratches can compromise its protective layer and lead to further deterioration. Unlike chip resistance, which prevents localized breaks from impact, scratch resistance ensures the enamel surface remains unmarred under everyday contact and friction.

Key Factors Influencing Enamel Chip Resistance

Enamel chip resistance is primarily influenced by factors such as enamel thickness, substrate preparation, and curing process, which enhance adhesion and durability against impact. Scratch resistance, while related, depends more on the hardness and flexibility of the enamel surface, affecting its ability to withstand abrasive forces without surface damage. Optimizing enamel formulations with durable fillers and improving surface tension during application further bolster chip resistance in high-performance coatings.

Variables Affecting Enamel Scratch Resistance

Enamel scratch resistance depends on factors such as the thickness of the enamel layer, its chemical composition, and curing process, which influence the hardness and bonding strength of the surface. Variables like the presence of fillers, firing temperature, and substrate material also affect the enamel's ability to withstand abrasions and mechanical wear. Understanding these variables helps optimize enamel formulations for enhanced durability against scratches.

Comparing Chip Resistance and Scratch Resistance in Enamel

Enamel chip resistance measures how well the coating withstands impacts that cause small fragments to break off, while scratch resistance assesses its ability to resist surface abrasions and fine lines. High chip resistance enamel formulations incorporate flexible binders and impact-absorbing fillers, whereas scratch resistance relies on harder surface materials and optimized curing processes to maintain smoothness. Understanding these differences guides the selection of enamel coatings for applications requiring durability against physical impacts or maintaining aesthetic surface integrity.

Common Testing Methods for Enamel Durability

Enamel chip resistance and scratch resistance are measured using standardized tests like the Impact Test and the Abrasion Test to evaluate enamel durability. The Impact Test quantifies enamel's ability to withstand sudden force or impacts without chipping, often using a weighted pendulum or drop-weight method. The Abrasion Test assesses scratch resistance by simulating wear through controlled friction or abrasive materials, ensuring enamel coatings maintain aesthetic and protective qualities under everyday use.

Impact of Manufacturing Processes on Enamel Toughness

Manufacturing processes significantly influence enamel toughness by altering its microstructure, which directly impacts chip and scratch resistance. High-temperature firing and controlled cooling enhance enamel adhesion and hardness, reducing the likelihood of chipping under impact stress. Variations in enamel composition and application techniques also contribute to the balance between resistance to surface scratches and deeper chips, optimizing durability for different industrial uses.

Real-World Applications: Choosing Between Chip and Scratch Resistance

Enamel chip resistance is crucial in environments prone to impact, such as automotive finishes and kitchenware, where small fragments can detach from the surface under sudden force. Scratch resistance is more relevant for high-contact surfaces like jewelry and electronic devices, where abrasion from everyday use can dull or damage the finish. Selecting enamel with the appropriate resistance depends on specific application demands, balancing durability against the type of wear encountered.

Improving Enamel Performance: Tips for Enhanced Durability

Enamel chip resistance depends on the material's ability to absorb impact without fracturing, which can be enhanced by applying thicker, more flexible enamel layers and using high-quality base materials to reduce brittleness. Scratch resistance improves with the inclusion of hardening agents and a smooth, well-cured surface that minimizes abrasion from external forces. Regular maintenance, such as gentle cleaning and avoiding abrasive tools, helps preserve both chip and scratch resistance, extending the enamel's overall durability.

Enamel chip resistance vs Scratch resistance Infographic

materialdif.com

materialdif.com