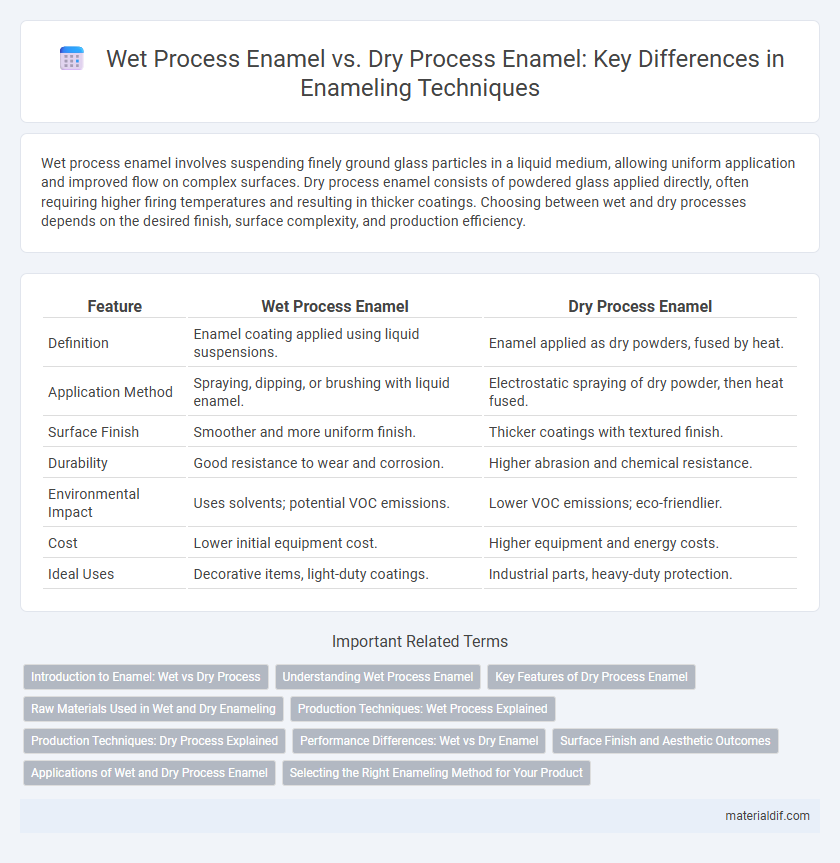

Wet process enamel involves suspending finely ground glass particles in a liquid medium, allowing uniform application and improved flow on complex surfaces. Dry process enamel consists of powdered glass applied directly, often requiring higher firing temperatures and resulting in thicker coatings. Choosing between wet and dry processes depends on the desired finish, surface complexity, and production efficiency.

Table of Comparison

| Feature | Wet Process Enamel | Dry Process Enamel |

|---|---|---|

| Definition | Enamel coating applied using liquid suspensions. | Enamel applied as dry powders, fused by heat. |

| Application Method | Spraying, dipping, or brushing with liquid enamel. | Electrostatic spraying of dry powder, then heat fused. |

| Surface Finish | Smoother and more uniform finish. | Thicker coatings with textured finish. |

| Durability | Good resistance to wear and corrosion. | Higher abrasion and chemical resistance. |

| Environmental Impact | Uses solvents; potential VOC emissions. | Lower VOC emissions; eco-friendlier. |

| Cost | Lower initial equipment cost. | Higher equipment and energy costs. |

| Ideal Uses | Decorative items, light-duty coatings. | Industrial parts, heavy-duty protection. |

Introduction to Enamel: Wet vs Dry Process

Wet process enamel involves mixing enamel powders with water to create a slurry that is sprayed or brushed onto surfaces, offering better adhesion and uniform coating thickness, ideal for intricate designs. Dry process enamel consists of applying dry enamel powders directly onto substrates before firing, providing a thicker, more durable finish often used in heavy-duty industrial applications. Both methods require precise firing temperatures between 750degC and 900degC to achieve optimal vitrification and gloss.

Understanding Wet Process Enamel

Wet process enamel involves mixing finely ground enamel frits with water to create a slurry that allows for uniform application on metal surfaces, ensuring excellent adhesion and a smooth finish. This method enhances the enamel's flow and leveling properties, resulting in superior coating durability and resistance to chipping and scratching. Wet process enamel is commonly used in industrial applications requiring consistent, high-quality surface coatings on appliances, cookware, and architectural components.

Key Features of Dry Process Enamel

Dry process enamel features a powder form that allows precise control over particle size and composition, resulting in uniform coating thickness and enhanced durability. It offers superior scratch resistance and better adhesion on metal surfaces compared to wet process enamel. This method reduces solvent use, minimizing environmental impact and improving workplace safety.

Raw Materials Used in Wet and Dry Enameling

Wet process enamel utilizes raw materials suspended in a liquid medium, primarily water-based suspensions of finely ground glass frit, pigments, and binders, allowing for smooth application and strong adhesion on metal substrates. Dry process enamel involves the use of powdered raw materials such as frit, oxides, and coloring agents, which are mixed and applied as a dry powder before firing, providing a thicker and more durable coating. The choice of raw materials directly influences the enamel's finish, durability, and resistance, with wet enameling favoring finer particle sizes and dry enameling requiring coarser powders for optimal performance.

Production Techniques: Wet Process Explained

Wet process enamel production involves mixing finely ground enamel powders with water to create a slurry, which is then sprayed or dipped onto metal surfaces. This technique ensures uniform coating thickness and reduces dust emission compared to dry processes. The controlled water content in the slurry allows for better adhesion and smoother finishes on complex shapes.

Production Techniques: Dry Process Explained

Dry process enamel production involves applying finely ground glass powders directly onto metal substrates without pre-wetting, enabling precise control of coating thickness and reducing the risk of bubbles or impurities. This technique typically employs electrostatic spray or dry powder coating methods, followed by firing in kilns at high temperatures to achieve a durable, smooth enamel surface. The dry process offers advantages such as improved surface quality and faster production cycles compared to wet process enameling.

Performance Differences: Wet vs Dry Enamel

Wet process enamel typically offers better adhesion and uniform coating due to its liquid application, enhancing corrosion resistance and surface smoothness. Dry process enamel, applied as a powder, provides superior thickness control and durability but may exhibit less flexibility under thermal stress. Performance differences between wet and dry enamel largely depend on the specific substrate and operating environment, influencing factors such as wear resistance, chemical stability, and finish quality.

Surface Finish and Aesthetic Outcomes

Wet process enamel offers a smoother surface finish with enhanced gloss and uniformity, ideal for high-quality aesthetic outcomes in decorative applications. Dry process enamel tends to produce a more textured surface, which can result in a matte or less polished appearance, suitable for industrial or utilitarian uses. The choice between wet and dry processes directly impacts the enamel's visual appeal, surface smoothness, and overall finish quality.

Applications of Wet and Dry Process Enamel

Wet process enamel is widely used in applications requiring smooth, high-gloss finishes such as automotive coatings, industrial appliances, and kitchenware due to its superior flow and uniform coverage. Dry process enamel finds application in high-temperature environments like electrical insulators, heat exchangers, and cookware, where durability and resistance to thermal shock are critical. Both enamel types offer specific advantages depending on the performance requirements, with wet process being favored for aesthetic appeal and dry process for thermal and mechanical resilience.

Selecting the Right Enameling Method for Your Product

Wet process enamel offers superior adhesion and a smoother finish ideal for complex shapes and detailed designs, making it suitable for products requiring high durability and aesthetic appeal. Dry process enamel provides faster application and curing times, optimizing production efficiency for large-scale manufacturing with consistent, matte textures. Choosing between wet and dry enameling depends on product requirements such as surface complexity, desired finish, and production speed to ensure optimal performance and cost-effectiveness.

Wet process enamel vs Dry process enamel Infographic

materialdif.com

materialdif.com