Low-temperature enamel offers vibrant colors and is easier to apply on delicate substrates, making it ideal for decorative pet collars and accessories. High-temperature enamel, firing above 1400degF, creates a durable, glossy finish that resists scratches and chemicals, suitable for heavy-use pet tags. Choosing between low and high-temperature enamel depends on the balance between aesthetic detail and long-lasting durability in pet products.

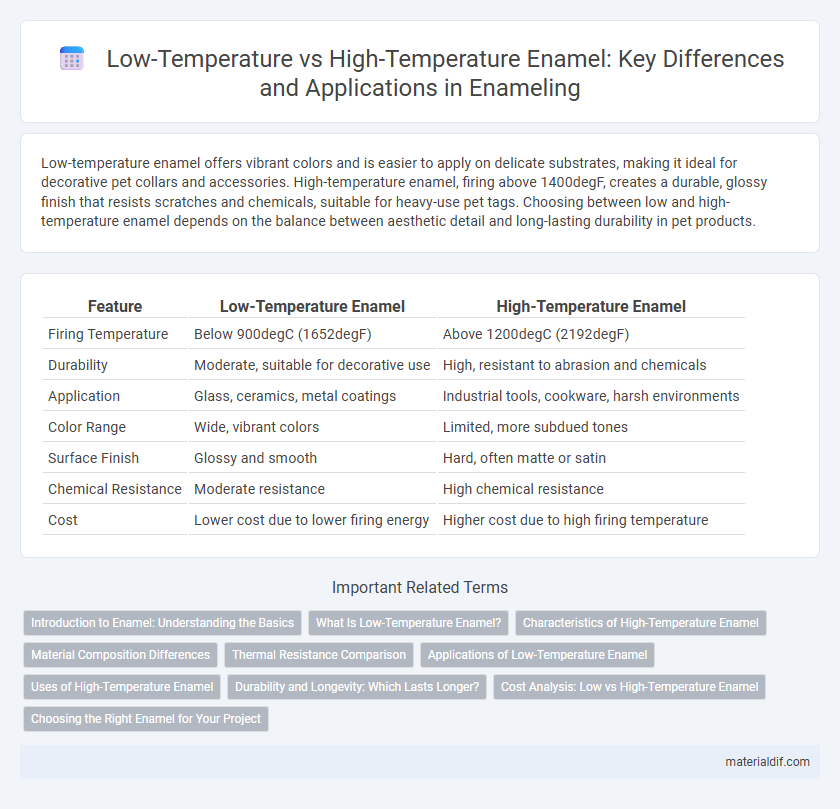

Table of Comparison

| Feature | Low-Temperature Enamel | High-Temperature Enamel |

|---|---|---|

| Firing Temperature | Below 900degC (1652degF) | Above 1200degC (2192degF) |

| Durability | Moderate, suitable for decorative use | High, resistant to abrasion and chemicals |

| Application | Glass, ceramics, metal coatings | Industrial tools, cookware, harsh environments |

| Color Range | Wide, vibrant colors | Limited, more subdued tones |

| Surface Finish | Glossy and smooth | Hard, often matte or satin |

| Chemical Resistance | Moderate resistance | High chemical resistance |

| Cost | Lower cost due to lower firing energy | Higher cost due to high firing temperature |

Introduction to Enamel: Understanding the Basics

Low-temperature enamel fuses at approximately 750-850degC, offering vibrant colors and quick firing times, ideal for delicate substrates and detailed artwork. High-temperature enamel requires firing above 800degC, providing superior durability, chemical resistance, and a stronger bond to metal surfaces. Understanding these temperature ranges helps in selecting the right enamel type for specific applications in jewelry, industrial coatings, and artistic creations.

What Is Low-Temperature Enamel?

Low-temperature enamel is a type of glass coating fired at temperatures typically between 550degC and 750degC, allowing it to bond to metal surfaces without damaging heat-sensitive materials. This enamel variant offers vibrant color options and fine detail suitable for decorative applications, such as jewelry and art pieces. Its lower firing range distinguishes it from high-temperature enamel, which requires temperatures above 800degC and caters to more durable industrial uses.

Characteristics of High-Temperature Enamel

High-temperature enamel is characterized by its superior durability and resistance to thermal shock, making it ideal for applications subjected to extreme heat, such as cookware and industrial equipment. It typically melts and fuses at temperatures above 850degC, providing a hard, glassy surface that resists corrosion and abrasion. The chemical stability of high-temperature enamel ensures long-lasting protection against environmental factors and mechanical wear.

Material Composition Differences

Low-temperature enamels typically contain a higher proportion of lead oxide and other fluxes that lower the melting point, enabling firing at temperatures between 700-850degC. High-temperature enamels are formulated with silica, boron, and alkali metal oxides, allowing them to withstand firing temperatures above 1200degC without compromising durability. The distinct material compositions influence thermal expansion, chemical resistance, and final coating hardness in applications ranging from decorative coatings to industrial machinery parts.

Thermal Resistance Comparison

Low-temperature enamel typically cures at temperatures between 450degC and 600degC, providing moderate thermal resistance suitable for decorative applications and light-duty industrial uses. High-temperature enamel withstands curing temperatures above 800degC, offering superior thermal stability and resistance to thermal shock, making it ideal for heavy-duty environments such as cookware and high-performance machinery. The enhanced durability of high-temperature enamel results in longer lifespan and better protection against oxidation and heat-induced degradation.

Applications of Low-Temperature Enamel

Low-temperature enamel is ideal for decorating complex metal objects and ceramics due to its ability to fuse at temperatures between 450degC and 800degC, preserving delicate substrates and intricate designs. It is commonly used in jewelry, art pieces, and electrical components where heat-sensitive materials require durable, vibrant coatings. This enamel also offers excellent chemical resistance and flexibility, making it suitable for household appliances and automotive parts that demand both aesthetic appeal and functional protection.

Uses of High-Temperature Enamel

High-temperature enamel is extensively used in applications requiring superior durability and resistance to thermal shock, such as industrial machinery, kitchenware, and automotive components. Its ability to withstand temperatures above 1200degC makes it ideal for protective coatings on engine parts, heat exchangers, and furnace linings. Compared to low-temperature enamel, high-temperature enamel provides enhanced corrosion resistance and mechanical strength in extreme environments.

Durability and Longevity: Which Lasts Longer?

Low-temperature enamel generally offers less durability compared to high-temperature enamel due to its lower firing temperature, which results in a softer surface prone to wear and scratching. High-temperature enamel, fired at temperatures above 1400degF (760degC), creates a stronger, more resilient coating that withstands abrasion and environmental factors better. Consequently, high-temperature enamel typically provides superior longevity, making it ideal for heavy-use applications requiring extended lifespan and resistance to damage.

Cost Analysis: Low vs High-Temperature Enamel

Low-temperature enamel requires less energy for firing, resulting in lower production costs compared to high-temperature enamel, which demands higher kiln temperatures and longer firing times. The material costs for low-temperature enamel are generally more economical due to simpler formulations, while high-temperature enamels often incorporate more expensive raw materials to achieve durability and heat resistance. Cost analysis reveals that low-temperature enamel offers budget-friendly options for products with moderate performance, whereas high-temperature enamel incurs higher upfront expenses justified by superior longevity and thermal stability.

Choosing the Right Enamel for Your Project

Low-temperature enamel is ideal for delicate substrates like glass and ceramics due to its lower firing point, typically between 500degC and 800degC, which prevents material damage. High-temperature enamel, firing above 800degC, offers superior durability and resistance to chemicals and wear, making it suitable for metal surfaces exposed to harsh conditions. Selecting the appropriate enamel depends on factors such as the substrate type, desired finish, and application environment to ensure optimal adhesion and longevity.

Low-temperature enamel vs high-temperature enamel Infographic

materialdif.com

materialdif.com