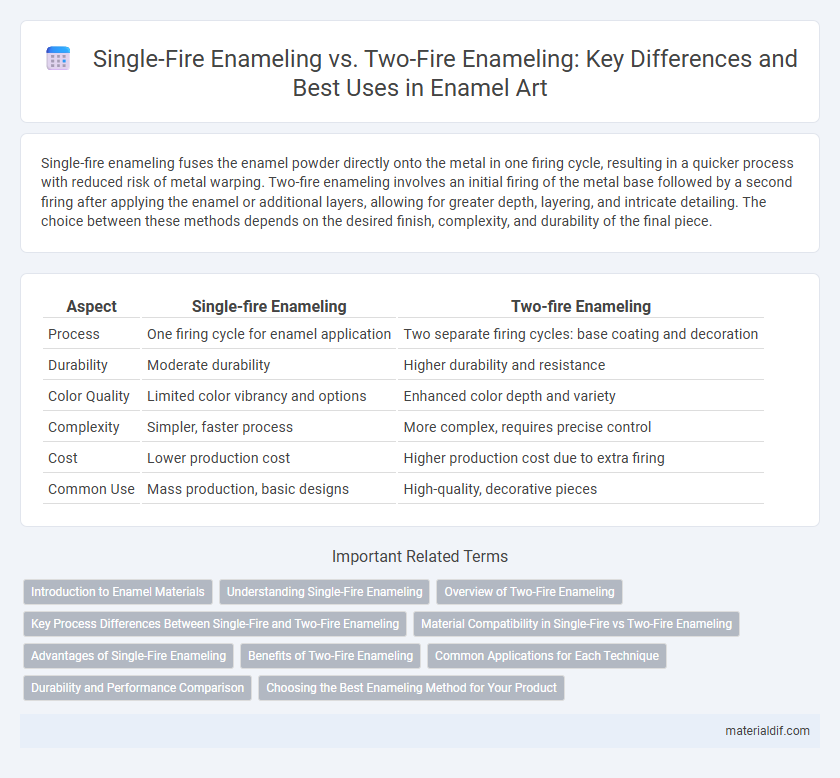

Single-fire enameling fuses the enamel powder directly onto the metal in one firing cycle, resulting in a quicker process with reduced risk of metal warping. Two-fire enameling involves an initial firing of the metal base followed by a second firing after applying the enamel or additional layers, allowing for greater depth, layering, and intricate detailing. The choice between these methods depends on the desired finish, complexity, and durability of the final piece.

Table of Comparison

| Aspect | Single-fire Enameling | Two-fire Enameling |

|---|---|---|

| Process | One firing cycle for enamel application | Two separate firing cycles: base coating and decoration |

| Durability | Moderate durability | Higher durability and resistance |

| Color Quality | Limited color vibrancy and options | Enhanced color depth and variety |

| Complexity | Simpler, faster process | More complex, requires precise control |

| Cost | Lower production cost | Higher production cost due to extra firing |

| Common Use | Mass production, basic designs | High-quality, decorative pieces |

Introduction to Enamel Materials

Enamel materials consist of finely ground glass powders fused onto metal surfaces, creating a durable and decorative coating. Single-fire enameling involves applying and firing enamel once, suitable for simpler designs and faster production, while two-fire enameling requires sequential firings for base layers and detailed decorations, enhancing color depth and texture. Understanding these processes is essential for selecting appropriate enamel materials and achieving desired aesthetic and functional properties in metalwork.

Understanding Single-Fire Enameling

Single-fire enameling involves fusing enamel powder to metal in one firing process, typically at temperatures ranging from 1400degF to 1600degF, resulting in a durable and glossy finish. This technique requires precise control of firing time and temperature to avoid over- or under-firing, which can cause defects such as blistering or dullness. Preferred for faster production and simpler designs, single-fire enameling is ideal for achieving consistent color and smooth surfaces on jewelry and decorative metalwares.

Overview of Two-Fire Enameling

Two-fire enameling involves applying a base layer of enamel and firing it at high temperatures before adding additional layers and firing again to achieve depth, texture, and enhanced color variation. This technique allows for more complex designs and greater control over enamel consistency and finish compared to single-fire enameling. Artists often prefer two-fire enameling for its ability to produce rich, multi-dimensional surfaces on metal jewelry and artwork.

Key Process Differences Between Single-Fire and Two-Fire Enameling

Single-fire enameling involves applying enamel onto a metal surface and firing it once at high temperature, resulting in a smooth, uniform coating ideal for quicker production. Two-fire enameling requires an initial firing of the metal base followed by enamel application and a second firing, offering enhanced control over detail and color layering. The key difference lies in process complexity, with two-fire enameling providing superior durability and depth through multiple firings compared to the efficiency of single-fire enameling.

Material Compatibility in Single-Fire vs Two-Fire Enameling

Single-fire enameling requires materials that can withstand a single high-temperature firing without distortion, favoring metals like copper and sterling silver due to their thermal stability. Two-fire enameling allows for greater material compatibility, enabling multiple firings at different temperatures, which accommodates delicate metals such as fine silver and gold-filled substrates. This flexibility in two-fire enameling reduces the risk of thermal stress, making it suitable for complex designs and mixed-metal compositions.

Advantages of Single-Fire Enameling

Single-fire enameling offers advantages such as reduced production time and lower energy consumption by eliminating the need for multiple firing cycles. This technique minimizes the risk of thermal shock and color distortion commonly associated with two-fire enameling. Additionally, it allows for greater precision in applying enamel layers, resulting in a smoother and more durable finish.

Benefits of Two-Fire Enameling

Two-fire enameling offers enhanced durability and color depth by allowing more precise control over each layer's firing temperature and duration, which reduces cracking and improves adhesion. This technique enables artists to apply multiple layers with distinct finishes, resulting in richer, more vibrant enamel surfaces. Compared to single-fire enameling, two-fire processes minimize imperfections and maximize the longevity of the enamel artwork.

Common Applications for Each Technique

Single-fire enameling is commonly used in jewelry making and decorative items where a quick, efficient process is needed to fuse enamel onto metal surfaces, often on copper or silver. Two-fire enameling finds its applications in higher-end jewelry and cloisonne work, allowing for additional layers of enamel to be applied and detailed without compromising the initial fusion. Automotive badges and high-durability industrial parts benefit from two-fire enameling due to the enhanced color depth and durability it provides.

Durability and Performance Comparison

Single-fire enameling involves applying and firing the enamel layer once, resulting in faster production but potentially less durability due to limited bonding time. Two-fire enameling includes an intermediate firing step after the base coat, enhancing adhesion and creating a stronger, more resilient surface that withstands wear and temperature fluctuations better. Consequently, two-fire enameling typically offers superior performance and longevity in applications requiring high durability.

Choosing the Best Enameling Method for Your Product

Single-fire enameling offers a faster, more cost-effective solution by applying color and glaze simultaneously, ideal for simpler designs and mass production. Two-fire enameling provides greater durability and richer color depth by firing the glaze and color separately, making it suitable for intricate artwork and high-quality products. Selecting the best enameling method depends on balancing production speed, budget, and desired finish quality for the specific application.

Single-fire enameling vs Two-fire enameling Infographic

materialdif.com

materialdif.com