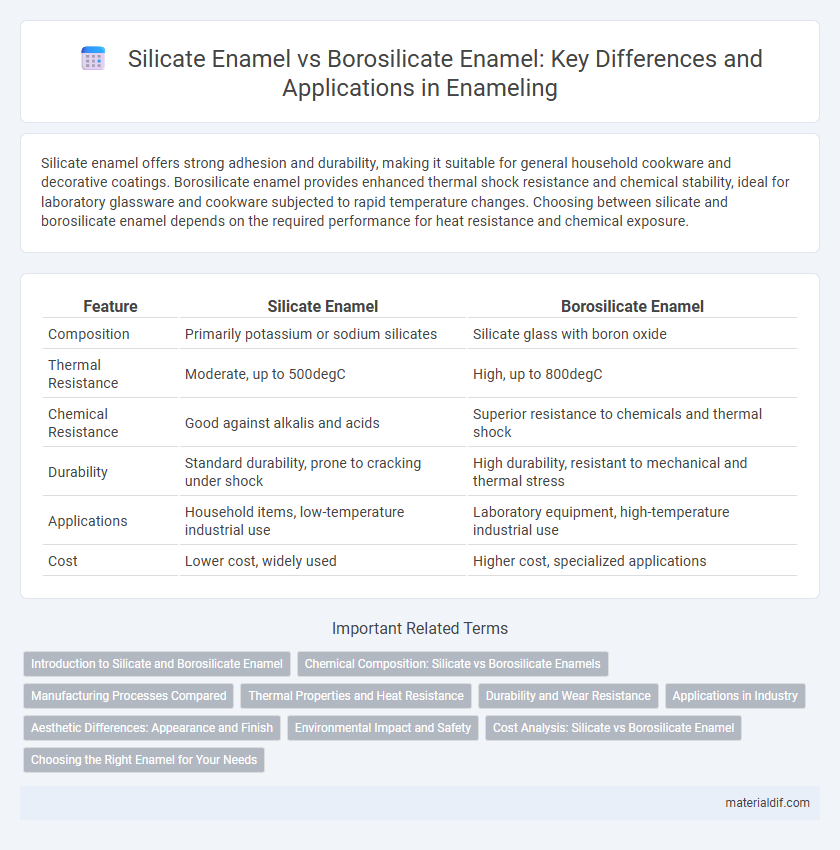

Silicate enamel offers strong adhesion and durability, making it suitable for general household cookware and decorative coatings. Borosilicate enamel provides enhanced thermal shock resistance and chemical stability, ideal for laboratory glassware and cookware subjected to rapid temperature changes. Choosing between silicate and borosilicate enamel depends on the required performance for heat resistance and chemical exposure.

Table of Comparison

| Feature | Silicate Enamel | Borosilicate Enamel |

|---|---|---|

| Composition | Primarily potassium or sodium silicates | Silicate glass with boron oxide |

| Thermal Resistance | Moderate, up to 500degC | High, up to 800degC |

| Chemical Resistance | Good against alkalis and acids | Superior resistance to chemicals and thermal shock |

| Durability | Standard durability, prone to cracking under shock | High durability, resistant to mechanical and thermal stress |

| Applications | Household items, low-temperature industrial use | Laboratory equipment, high-temperature industrial use |

| Cost | Lower cost, widely used | Higher cost, specialized applications |

Introduction to Silicate and Borosilicate Enamel

Silicate enamel is composed primarily of silica (SiO2) combined with alkali and alkaline earth metals, offering excellent chemical resistance and a smooth, glossy finish ideal for decorative and protective coatings. Borosilicate enamel incorporates boron oxide (B2O3) into the silica matrix, enhancing thermal stability and resistance to thermal shock, making it suitable for cookware and industrial applications. Both silicate and borosilicate enamels provide durable, non-porous surfaces, but borosilicate enamel's superior heat resistance differentiates it in high-temperature environments.

Chemical Composition: Silicate vs Borosilicate Enamels

Silicate enamel primarily consists of silica (SiO2) combined with metal oxides, offering a durable, glossy surface resistant to scratches and heat. Borosilicate enamel incorporates boron oxide (B2O3) within its silica matrix, enhancing thermal resistance and chemical stability, making it suitable for high-temperature applications. The presence of boron in borosilicate enamel reduces thermal expansion, providing greater resistance to thermal shock compared to standard silicate enamel.

Manufacturing Processes Compared

Silicate enamel manufacturing involves fusing a mixture of silica, alkali, and metal oxides at temperatures between 750degC and 850degC, resulting in a glassy, durable coating. Borosilicate enamel incorporates boron oxide into the silicate base, requiring higher firing temperatures around 850degC to 1000degC, which enhances thermal resistance and chemical durability. The borosilicate process demands precise control over raw materials and firing schedules to achieve improved mechanical strength and resistance to thermal shock compared to traditional silicate enamel.

Thermal Properties and Heat Resistance

Silicate enamel typically offers moderate thermal resistance with a coefficient of thermal expansion around 14-16 x 10^-6/K, making it suitable for everyday applications but less ideal for extreme temperature fluctuations. Borosilicate enamel exhibits superior heat resistance due to its lower coefficient of thermal expansion of approximately 3.3 x 10^-6/K, enabling it to withstand rapid temperature changes and high thermal shock without cracking. This enhanced thermal stability makes borosilicate enamel preferred for laboratory glassware and cookware exposed to intense heat.

Durability and Wear Resistance

Silicate enamel offers good durability and wear resistance due to its strong silica base, making it suitable for general industrial applications. Borosilicate enamel enhances these properties with added boron oxide, resulting in superior thermal stability and resistance to chemical corrosion, which significantly extends its lifespan in harsh environments. The borosilicate composition provides improved toughness and scratch resistance compared to standard silicate enamel, making it ideal for high-performance coatings.

Applications in Industry

Silicate enamel offers excellent resistance to chemical corrosion and is widely used in industrial applications such as cookware, laboratory equipment, and architectural cladding due to its durability and aesthetic flexibility. Borosilicate enamel exhibits superior thermal shock resistance and is preferred in high-temperature industrial environments, including chemical reactors, heat exchangers, and automotive parts exposed to rapid temperature changes. Both enamels enhance surface protection, with silicate enamel favoring chemical stability and borosilicate enamel optimizing performance under thermal stress.

Aesthetic Differences: Appearance and Finish

Silicate enamel typically offers a glossy and vibrant finish with rich color depth, making it ideal for decorative applications where aesthetics are a priority. Borosilicate enamel, on the other hand, provides a more matte or satin finish with subtle color variations due to its chemical composition, enhancing the surface's textured and sophisticated appearance. The difference in finish between silicate and borosilicate enamels influences the choice for design projects requiring specific visual effects and durability.

Environmental Impact and Safety

Silicate enamel offers moderate environmental benefits due to its lower processing energy but may release trace amounts of heavy metals during manufacturing, impacting safety. Borosilicate enamel demonstrates superior chemical durability and thermal resistance, reducing the frequency of replacements and thus lowering overall environmental impact. Its composition minimizes hazardous emissions, making it a safer choice for both producers and end-users in enamel applications.

Cost Analysis: Silicate vs Borosilicate Enamel

Silicate enamel typically offers a lower cost option due to its simpler chemical composition and widespread availability of raw materials. Borosilicate enamel, incorporating boron oxide, demands higher production expenses reflecting enhanced thermal and chemical resistance properties. Cost analysis favors silicate for budget-conscious projects, while borosilicate's premium pricing aligns with applications requiring superior durability and performance.

Choosing the Right Enamel for Your Needs

Silicate enamel offers excellent hardness and resistance to abrasion, making it ideal for industrial coatings and heavy-duty applications, while borosilicate enamel provides superior thermal shock resistance and chemical durability, suitable for cookware and laboratory equipment. Selecting the right enamel depends on factors such as exposure to temperature fluctuations, chemical contact, and mechanical wear. Understanding the specific properties of silicate versus borosilicate enamel ensures optimal performance and longevity for your project or product.

Silicate enamel vs Borosilicate enamel Infographic

materialdif.com

materialdif.com