Enamel offers superior durability and resistance to chipping compared to glass, making it ideal for cookware and decorative surfaces. Its smooth, non-porous finish prevents staining and is easy to clean, unlike glass which can be more fragile and prone to scratches. Enamel's vibrant colors and heat resistance provide versatile design options that glass cannot match.

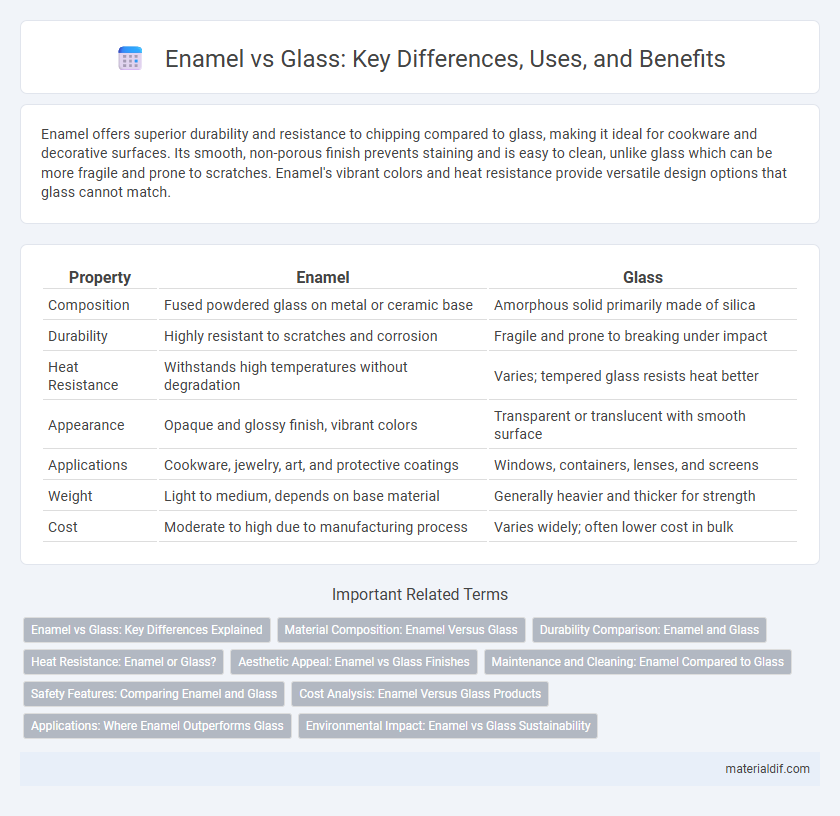

Table of Comparison

| Property | Enamel | Glass |

|---|---|---|

| Composition | Fused powdered glass on metal or ceramic base | Amorphous solid primarily made of silica |

| Durability | Highly resistant to scratches and corrosion | Fragile and prone to breaking under impact |

| Heat Resistance | Withstands high temperatures without degradation | Varies; tempered glass resists heat better |

| Appearance | Opaque and glossy finish, vibrant colors | Transparent or translucent with smooth surface |

| Applications | Cookware, jewelry, art, and protective coatings | Windows, containers, lenses, and screens |

| Weight | Light to medium, depends on base material | Generally heavier and thicker for strength |

| Cost | Moderate to high due to manufacturing process | Varies widely; often lower cost in bulk |

Enamel vs Glass: Key Differences Explained

Enamel is a durable, glass-like coating fused to metal at high temperatures, providing a smooth, glossy finish resistant to corrosion and heat. Unlike traditional glass, enamel features enhanced adhesion to surfaces and greater impact resistance, making it suitable for cookware, jewelry, and industrial applications. Glass, in contrast, is a brittle, non-porous material often used for windows and containers but lacks the flexibility and durability of enamel coatings.

Material Composition: Enamel Versus Glass

Enamel is a durable, vitreous coating made by fusing powdered glass to a metal substrate at high temperatures, creating a strong bond that resists corrosion and wear. Glass, primarily composed of silica, soda ash, and lime, lacks the metal base and fusion process that characterize enamel, making it more brittle and less impact-resistant. The key distinction lies in enamel's integration with metal through vitrification, resulting in enhanced toughness and long-lasting surface protection compared to standalone glass.

Durability Comparison: Enamel and Glass

Enamel demonstrates superior durability compared to glass due to its resistance to scratching, chipping, and heat exposure, making it ideal for cookware and industrial applications. While glass can be fragile and prone to cracking under thermal shock or impact, enamel's tough, fused coating provides a resilient, protective barrier that extends product lifespan. The enhanced durability of enamel reduces replacement frequency and maintenance costs, making it a cost-effective choice in environments demanding robustness.

Heat Resistance: Enamel or Glass?

Enamel exhibits superior heat resistance compared to glass, withstanding temperatures up to 1,600degF (870degC) without melting or warping, whereas most glass types begin to soften around 1,100degF (593degC). This makes enamel ideal for cookware and industrial applications requiring high thermal stability. The crystalline structure of enamel, fused to metal substrates, enhances its durability under rapid temperature changes compared to brittle glass surfaces.

Aesthetic Appeal: Enamel vs Glass Finishes

Enamel finishes offer a rich, vibrant aesthetic with deep color saturation and a smooth, glossy surface that resists fading and chipping over time. Glass finishes provide a sleek, reflective quality with high light transmission, creating a modern and luminous appeal but can be more prone to scratches and fingerprints. The choice between enamel and glass depends on desired visual impact: enamel for bold, enduring color depth, glass for brilliance and contemporary clarity.

Maintenance and Cleaning: Enamel Compared to Glass

Enamel surfaces offer superior durability and resistance to scratches and stains compared to glass, making maintenance easier and less frequent. Enamel can be cleaned effectively with mild detergents and non-abrasive cloths, avoiding harsh chemicals that may damage its finish, whereas glass requires regular polishing to maintain clarity and is more prone to showing fingerprints and smudges. The non-porous nature of enamel reduces bacterial buildup, enhancing hygiene with simple cleaning routines, unlike glass which may need constant attention to prevent water spots and streaks.

Safety Features: Comparing Enamel and Glass

Enamel surfaces offer superior safety features compared to glass due to their resistance to shattering and high heat tolerance, making them ideal for kitchen and industrial applications. Unlike glass, enamel is less prone to breakage on impact, reducing risks of injury from sharp fragments. Its non-porous, easy-to-clean nature also prevents bacterial buildup, enhancing overall health safety.

Cost Analysis: Enamel Versus Glass Products

Enamel products typically offer a more cost-effective solution compared to glass due to lower production and material expenses, making them ideal for budget-conscious projects. Glass items often incur higher costs related to fragility, packaging, and shipping, which increase the overall investment. Evaluating the long-term durability and maintenance costs reveals enamel's advantage in resisting chips and scratches, thereby reducing replacement and repair expenditures over time.

Applications: Where Enamel Outperforms Glass

Enamel excels over glass in high-temperature applications such as cookware and industrial equipment due to its superior thermal shock resistance and durability. Its chemical resistance makes it ideal for protective coatings on metal surfaces exposed to aggressive environments. Enamel's ability to bond permanently to metals provides long-lasting aesthetic and functional benefits that glass cannot match in heavy-use or corrosive settings.

Environmental Impact: Enamel vs Glass Sustainability

Enamel production typically involves higher energy consumption compared to glass, but it benefits from durability and long lifespan, reducing waste over time. Glass is more recyclable and has a lower carbon footprint in manufacturing, making it a more sustainable choice in terms of raw material reuse. Both materials offer eco-friendly advantages, but glass leads in circularity while enamel excels in longevity and reduced replacement frequency.

Enamel vs Glass Infographic

materialdif.com

materialdif.com