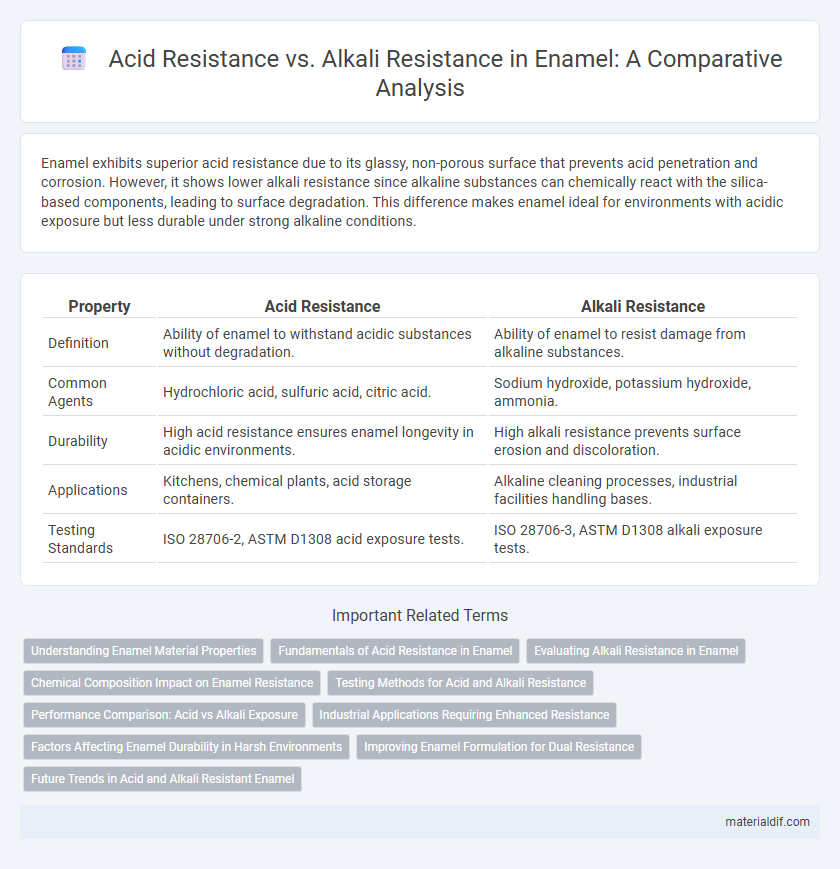

Enamel exhibits superior acid resistance due to its glassy, non-porous surface that prevents acid penetration and corrosion. However, it shows lower alkali resistance since alkaline substances can chemically react with the silica-based components, leading to surface degradation. This difference makes enamel ideal for environments with acidic exposure but less durable under strong alkaline conditions.

Table of Comparison

| Property | Acid Resistance | Alkali Resistance |

|---|---|---|

| Definition | Ability of enamel to withstand acidic substances without degradation. | Ability of enamel to resist damage from alkaline substances. |

| Common Agents | Hydrochloric acid, sulfuric acid, citric acid. | Sodium hydroxide, potassium hydroxide, ammonia. |

| Durability | High acid resistance ensures enamel longevity in acidic environments. | High alkali resistance prevents surface erosion and discoloration. |

| Applications | Kitchens, chemical plants, acid storage containers. | Alkaline cleaning processes, industrial facilities handling bases. |

| Testing Standards | ISO 28706-2, ASTM D1308 acid exposure tests. | ISO 28706-3, ASTM D1308 alkali exposure tests. |

Understanding Enamel Material Properties

Enamel exhibits superior acid resistance due to its dense, glassy surface that prevents acid penetration and erosion, making it ideal for environments with low pH exposure. Alkali resistance, however, is generally lower since alkaline substances can cause surface degradation and increased porosity in enamel material. Understanding the differential resistance is crucial for selecting enamel coatings in applications where chemical durability against specific substances is required.

Fundamentals of Acid Resistance in Enamel

Acid resistance in enamel is primarily determined by the composition and microstructure of the glassy matrix, which controls ion exchange and dissolution rates when exposed to acidic environments. The presence of alumina and silica enhances chemical durability by forming a stable aluminosilicate network that resists proton attacks. In contrast, alkali resistance relies on minimizing the leaching of alkali ions, which requires different structural considerations focused on alkaline stability rather than proton resistance.

Evaluating Alkali Resistance in Enamel

Alkali resistance in enamel is crucial for applications exposed to high pH environments, where alkaline substances can cause surface degradation and structural weakening. Evaluating alkali resistance involves subjecting enamel samples to alkaline solutions such as sodium hydroxide or potassium hydroxide, followed by assessments of surface hardness, gloss retention, and microstructural integrity using techniques like scanning electron microscopy (SEM) and hardness testing. Comparing these results with acid resistance data highlights enamel's suitability for environments where alkali exposure is predominant, informing material selection and formulation optimization.

Chemical Composition Impact on Enamel Resistance

Enamel demonstrates higher acid resistance due to its dense hydroxyapatite crystal structure, which limits acid penetration and enamel erosion. Alkali resistance is influenced by the presence of silica and alumina in the enamel's mineral matrix, which help neutralize alkaline solutions and reduce surface degradation. The chemical composition, particularly the balance of calcium, phosphate, and trace elements, directly impacts enamel's durability against acidic and alkaline environments.

Testing Methods for Acid and Alkali Resistance

Acid and alkali resistance of enamel is commonly evaluated using standardized immersion tests, where samples are exposed to specific acidic or alkaline solutions for defined durations and concentrations, followed by surface analysis for degradation or etching. Techniques like weight loss measurement, gloss retention, and microscopic examination assess the enamel's durability against corrosive substances. Advanced methods include electrochemical impedance spectroscopy and pH cycling tests to simulate real-world acid and alkali exposure, providing detailed insights into enamel's protective properties.

Performance Comparison: Acid vs Alkali Exposure

Enamel demonstrates superior acid resistance by maintaining surface integrity and gloss when exposed to acidic environments, preventing erosion and discoloration. In contrast, alkali exposure can cause more substantial degradation, including surface roughening and potential chemical breakdown of the enamel matrix. Performance comparison reveals enamel's enhanced durability against acids but a relative vulnerability to alkaline substances, influencing its application in chemically varied settings.

Industrial Applications Requiring Enhanced Resistance

Enamel coatings exhibit superior acid resistance essential for industrial applications such as chemical tanks, acid storage vessels, and pharmaceutical equipment exposed to corrosive acidic environments. Alkali resistance in enamel is critical for industries including soap manufacturing, paper processing, and cleaning product containment, where high pH substances can degrade lesser materials. Selecting enamel formulations tailored for either acid or alkali resistance ensures durability, reduces maintenance costs, and improves safety in harsh chemical processing settings.

Factors Affecting Enamel Durability in Harsh Environments

Enamel durability in harsh environments is significantly influenced by its acid resistance and alkali resistance, which depend on its chemical composition, firing temperature, and thickness. High silica content and optimal firing conditions enhance acid resistance by forming a dense, glassy surface that resists corrosion. Conversely, alkali resistance improves with reduced flux content and increased alumina, which prevent surface degradation and maintain structural integrity under alkaline exposure.

Improving Enamel Formulation for Dual Resistance

Enhancing enamel formulation to achieve dual resistance involves optimizing the balance between acid resistance and alkali resistance, ensuring durability in both corrosive environments. Incorporating specific inorganic fillers and stabilizers, such as alumina and zirconia, can significantly increase enamel's resistance to acidic and alkaline attack. Advanced silicate-based binders and phosphate additives contribute to a robust enamel matrix that withstands pH extremes, extending the lifespan and performance of coated surfaces.

Future Trends in Acid and Alkali Resistant Enamel

Future trends in acid and alkali resistant enamel emphasize enhanced formulations integrating nanotechnology to improve durability and chemical stability. Advances in hybrid organic-inorganic coatings are driving better protection against highly corrosive environments, extending the lifespan of industrial equipment. Research into eco-friendly, sustainable materials is also gaining momentum to comply with stricter environmental regulations while maintaining superior resistance properties.

Acid resistance vs Alkali resistance Infographic

materialdif.com

materialdif.com