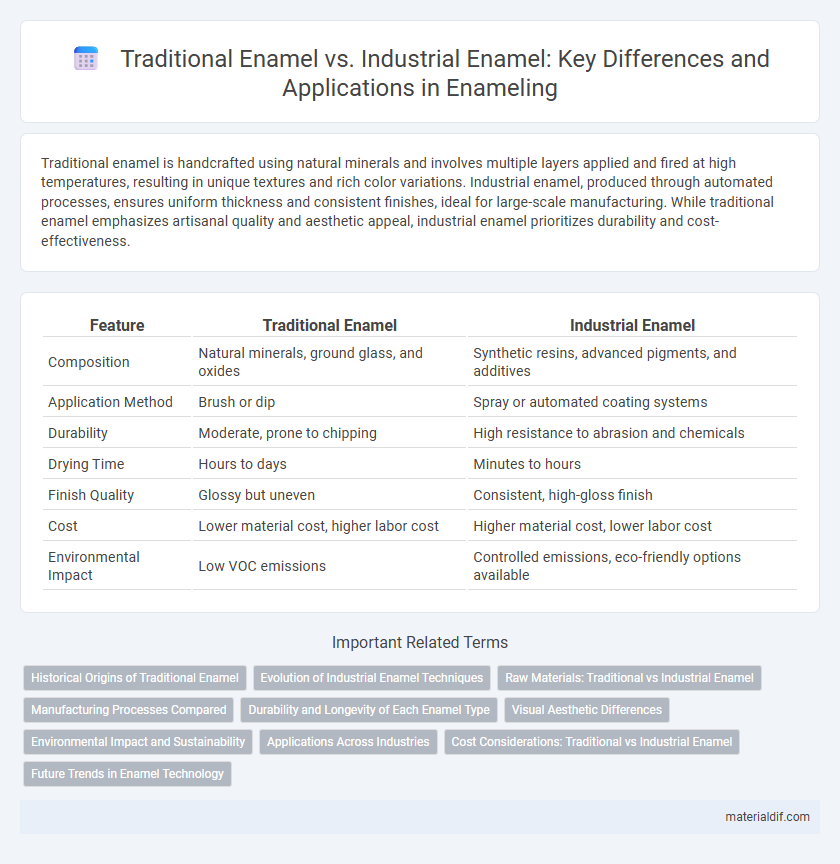

Traditional enamel is handcrafted using natural minerals and involves multiple layers applied and fired at high temperatures, resulting in unique textures and rich color variations. Industrial enamel, produced through automated processes, ensures uniform thickness and consistent finishes, ideal for large-scale manufacturing. While traditional enamel emphasizes artisanal quality and aesthetic appeal, industrial enamel prioritizes durability and cost-effectiveness.

Table of Comparison

| Feature | Traditional Enamel | Industrial Enamel |

|---|---|---|

| Composition | Natural minerals, ground glass, and oxides | Synthetic resins, advanced pigments, and additives |

| Application Method | Brush or dip | Spray or automated coating systems |

| Durability | Moderate, prone to chipping | High resistance to abrasion and chemicals |

| Drying Time | Hours to days | Minutes to hours |

| Finish Quality | Glossy but uneven | Consistent, high-gloss finish |

| Cost | Lower material cost, higher labor cost | Higher material cost, lower labor cost |

| Environmental Impact | Low VOC emissions | Controlled emissions, eco-friendly options available |

Historical Origins of Traditional Enamel

Traditional enamel has origins dating back to ancient civilizations such as the Egyptians and Byzantines, who developed intricate enamel techniques for decorative art and jewelry. This form of enamel uses powdered glass fused onto metal surfaces through high-temperature kiln firing, creating durable and vibrant finishes. Unlike industrial enamel, which emphasizes mass production and uniform coatings, traditional enamel focuses on handcrafted detail and historical craftsmanship methods.

Evolution of Industrial Enamel Techniques

Industrial enamel techniques have evolved significantly from traditional methods, incorporating advanced formulations and precise application processes to enhance durability and uniformity. Modern industrial enameling utilizes automated spraying and controlled firing environments, improving adhesion and resistance to corrosion compared to hand-applied traditional enamel. Innovations in chemical compositions, such as the introduction of frits and synthetic pigments, have optimized color consistency and surface hardness in industrial enamel coatings.

Raw Materials: Traditional vs Industrial Enamel

Traditional enamel relies on natural raw materials such as feldspar, quartz, and soda ash, combined with finely ground glass and natural minerals to create a smooth, glossy finish. Industrial enamel incorporates synthetic raw materials and chemical additives to enhance durability, chemical resistance, and uniformity during large-scale production. The choice of raw materials directly impacts the enamel's hardness, color consistency, and resistance to heat and corrosion in different applications.

Manufacturing Processes Compared

Traditional enamel manufacturing involves manual application of enamel powders onto metal surfaces followed by firing in kilns at high temperatures, allowing for detailed craftsmanship and artisanal finishes. Industrial enamel production utilizes automated processes such as robotic spraying and continuous conveyor kilns, enabling high-volume, consistent coatings with precise thickness control. The industrial approach significantly reduces production time and labor costs while maintaining durable, corrosion-resistant surfaces suitable for mass-market appliances and cookware.

Durability and Longevity of Each Enamel Type

Traditional enamel, often composed of natural raw materials and applied through manual processes, tends to exhibit superior durability due to its thicker protective layer and resistance to chipping and scratching. Industrial enamel, produced using advanced manufacturing techniques and synthetic compounds, offers consistent quality and enhanced resistance to environmental factors like corrosion and UV exposure, extending its longevity in industrial applications. Both enamel types provide durable coatings, but traditional enamel excels in longevity through natural resilience, while industrial enamel benefits from precision-engineered formulations for specific durability needs.

Visual Aesthetic Differences

Traditional enamel showcases rich, handcrafted textures with subtle color variations and depth, resulting in a unique and artisanal finish. Industrial enamel offers a more uniform, glossy surface with consistent color and smoothness ideal for mass production. The choice between traditional and industrial enamel significantly impacts the visual appeal, texture complexity, and perceived craftsmanship of the final product.

Environmental Impact and Sustainability

Traditional enamel production relies on natural raw materials and low-energy firing processes, resulting in minimal environmental impact and high sustainability due to its long lifespan and recyclability. Industrial enamel manufacturing often involves synthetic chemicals and higher energy consumption, leading to increased greenhouse gas emissions and waste generation. Sustainable practices are improving in industrial enamel with innovations in eco-friendly materials and energy-efficient technologies that reduce its carbon footprint.

Applications Across Industries

Traditional enamel is widely used in artisanal crafts, jewelry, and decorative objects due to its vibrant colors and intricate detailing capabilities. Industrial enamel finds extensive applications in cookware, automotive parts, and architectural panels where durability, heat resistance, and corrosion protection are critical. Both types serve specific industry needs, with traditional enamel excelling in aesthetic appeal and industrial enamel prioritizing functional performance.

Cost Considerations: Traditional vs Industrial Enamel

Traditional enamel typically incurs higher costs due to labor-intensive application methods and the use of artisanal materials, which contribute to its premium pricing. Industrial enamel benefits from automated production processes and bulk material procurement, resulting in lower per-unit costs and greater affordability. Cost considerations also include factors such as durability and maintenance, where industrial enamel often offers enhanced longevity, reducing long-term expenses.

Future Trends in Enamel Technology

Traditional enamel, crafted through manual layering and firing processes, offers unique artisanal qualities but faces limitations in scalability and durability. Industrial enamel leverages advanced automation and chemical formulations, enhancing consistency, wear resistance, and environmental sustainability. Future trends focus on nanotechnology integration, eco-friendly materials, and smart coatings to revolutionize enamel applications across automotive, cookware, and architectural industries.

Traditional enamel vs industrial enamel Infographic

materialdif.com

materialdif.com