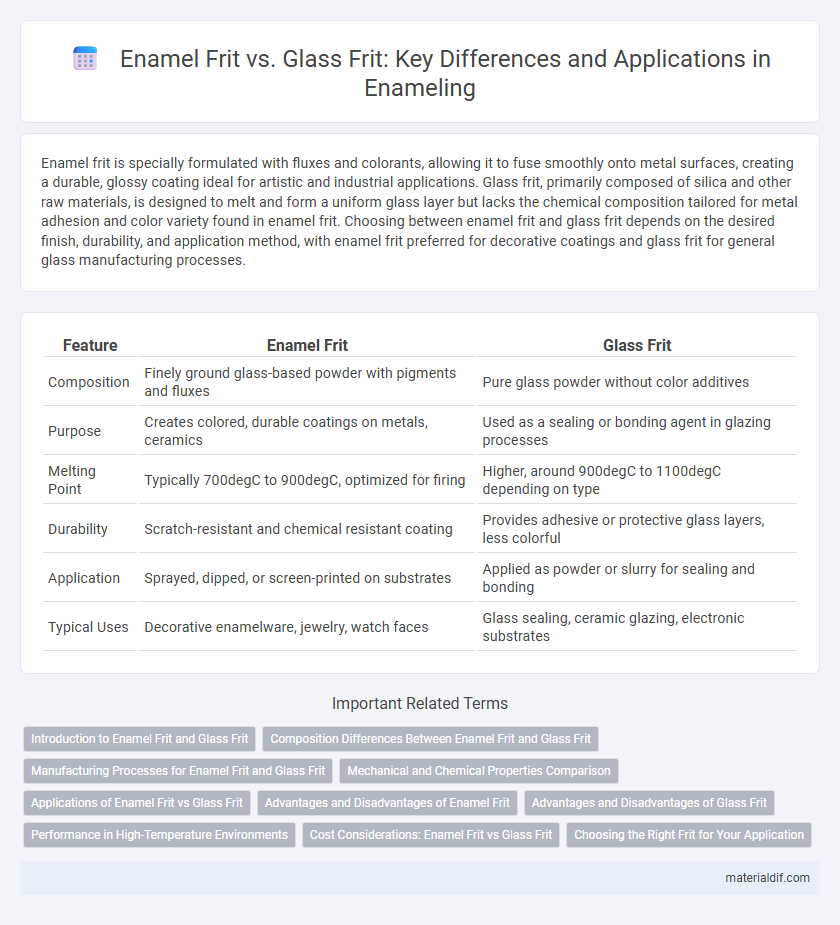

Enamel frit is specially formulated with fluxes and colorants, allowing it to fuse smoothly onto metal surfaces, creating a durable, glossy coating ideal for artistic and industrial applications. Glass frit, primarily composed of silica and other raw materials, is designed to melt and form a uniform glass layer but lacks the chemical composition tailored for metal adhesion and color variety found in enamel frit. Choosing between enamel frit and glass frit depends on the desired finish, durability, and application method, with enamel frit preferred for decorative coatings and glass frit for general glass manufacturing processes.

Table of Comparison

| Feature | Enamel Frit | Glass Frit |

|---|---|---|

| Composition | Finely ground glass-based powder with pigments and fluxes | Pure glass powder without color additives |

| Purpose | Creates colored, durable coatings on metals, ceramics | Used as a sealing or bonding agent in glazing processes |

| Melting Point | Typically 700degC to 900degC, optimized for firing | Higher, around 900degC to 1100degC depending on type |

| Durability | Scratch-resistant and chemical resistant coating | Provides adhesive or protective glass layers, less colorful |

| Application | Sprayed, dipped, or screen-printed on substrates | Applied as powder or slurry for sealing and bonding |

| Typical Uses | Decorative enamelware, jewelry, watch faces | Glass sealing, ceramic glazing, electronic substrates |

Introduction to Enamel Frit and Glass Frit

Enamel frit consists of finely ground, pre-melted glass particles specifically formulated to fuse onto metal surfaces, creating a durable, glossy coating often used in decorative and protective applications. Glass frit, a similar powdered glass material, generally serves broader industrial purposes such as ceramics, glazes, and composites, where melting and bonding properties vary based on composition. Both enamel frit and glass frit undergo controlled melting processes, but enamel frit is engineered to achieve optimal adhesion and color stability on metal substrates.

Composition Differences Between Enamel Frit and Glass Frit

Enamel frit is primarily composed of silica, fluxes, and stabilizers designed to create a durable, glossy coating when fused to metal surfaces, whereas glass frit focuses on forming a uniform, smooth glassy layer with a higher proportion of silica and alkaline earth oxides. The key compositional difference lies in enamel frit containing metal oxides like boron oxide and lead oxide to enhance adhesion and chemical resistance, unlike glass frit, which may have a simpler mix aimed at aesthetic or insulating properties. These variations in composition directly influence their distinct melting temperatures, surface hardness, and suitability for different industrial applications such as jewelry or electronics.

Manufacturing Processes for Enamel Frit and Glass Frit

Enamel frit manufacturing involves melting a blend of raw materials such as silica, fluxes, and colorants at high temperatures before rapidly cooling to form glassy particles, ensuring chemical durability and smooth fusion on metal surfaces. Glass frit production follows a similar melting and quenching process but is often tailored for specific applications like ceramics or electronics, with variations in composition and particle size to optimize thermal and mechanical properties. Precise control over melting temperatures and cooling rates during both enamel and glass frit manufacturing directly impacts the final frit's quality, reactivity, and performance in coating or bonding processes.

Mechanical and Chemical Properties Comparison

Enamel frit, composed primarily of finely ground glass fused with oxides, offers superior chemical resistance and enhanced mechanical durability due to its vitrified surface, which withstands corrosion and abrasion better than standard glass frit. Glass frit, mainly silica-based with fluxing agents, exhibits lower hardness and is more prone to chemical degradation and surface wear under mechanical stress. The fusion process in enamel frit results in a denser, more chemically stable coating, making it ideal for applications requiring high resistance to acids, alkalis, and mechanical impact.

Applications of Enamel Frit vs Glass Frit

Enamel frit is primarily applied in coating metals, ceramics, and glass to provide a durable, glossy, and chemical-resistant surface, ideal for cookware, signage, and architectural panels. Glass frit is commonly used in ceramics, electronics, and glass-to-metal sealing due to its ability to fuse at lower temperatures and create strong, hermetic seals. The choice between enamel and glass frit depends on application requirements such as temperature resistance, surface finish, and bonding properties.

Advantages and Disadvantages of Enamel Frit

Enamel frit offers superior durability and chemical resistance compared to glass frit, making it ideal for applications requiring long-lasting coatings and vibrant finishes. However, enamel frit typically requires higher firing temperatures and can be more brittle, posing challenges during manufacturing and increasing the risk of cracking. Its advantage in color retention and hardness is balanced by the complexity and cost of processing relative to glass frit.

Advantages and Disadvantages of Glass Frit

Glass frit offers superior durability and chemical resistance compared to enamel frit, making it ideal for high-temperature applications and corrosion-prone environments. However, glass frit typically requires higher melting temperatures and longer firing times, increasing energy costs and processing complexity. Its rigidity can limit adhesion on certain metals, potentially causing cracking or chipping under mechanical stress.

Performance in High-Temperature Environments

Enamel frit exhibits superior thermal stability and chemical resistance compared to glass frit, making it ideal for high-temperature applications. Its composition allows it to withstand rapid temperature changes without cracking or degrading, ensuring long-lasting durability in environments exceeding 800degC. Glass frit, while effective for lower-temperature processes, often softens or deteriorates under extreme heat, limiting its performance in industrial settings requiring robust thermal endurance.

Cost Considerations: Enamel Frit vs Glass Frit

Enamel frit typically incurs higher production costs than glass frit due to its specialized formulation and firing requirements, making it less economical for large-scale applications. Glass frit offers a more cost-effective solution with lower raw material expenses and simpler manufacturing processes, ideal for budget-sensitive projects. Cost considerations also include durability and finish quality, where enamel frit may justify its premium price through enhanced wear resistance and aesthetic appeal.

Choosing the Right Frit for Your Application

Enamel frit, composed primarily of finely ground glass and oxides, is formulated to fuse smoothly onto metal surfaces, providing durability and vivid color options ideal for decorative and protective coatings. Glass frit, while similar in composition, is designed mainly for vitrification processes in ceramics or glass products, offering excellent thermal stability and chemical resistance but lacking enamel's adhesion properties. Selecting the right frit depends on the substrate and desired finish; enamel frit suits metal enameling for corrosion resistance and aesthetic appeal, whereas glass frit is optimal for applications requiring high-temperature firing and structural integrity.

Enamel Frit vs Glass Frit Infographic

materialdif.com

materialdif.com